WARNINGS

Read, understand, and follow all instructions, warnings, and cautions before using this equipment. Failure to do so

could result in your serious injury or death.

This product is designed to be used by a person with a maximum weight of 350 lbs. when fully equipped.

Fall protection equipment, (i.e. fall arrest, work positioning belts, climbers, retrieval, suspension etc.) should

notbe resold or provided to others for re-use after use by original user as assurance cannot be granted that a

used product meets criteria of applicable standards and is safe for use to a subsequent user.

KNOW and FOLLOW ANSI Z133.1 for Tree Care Operations

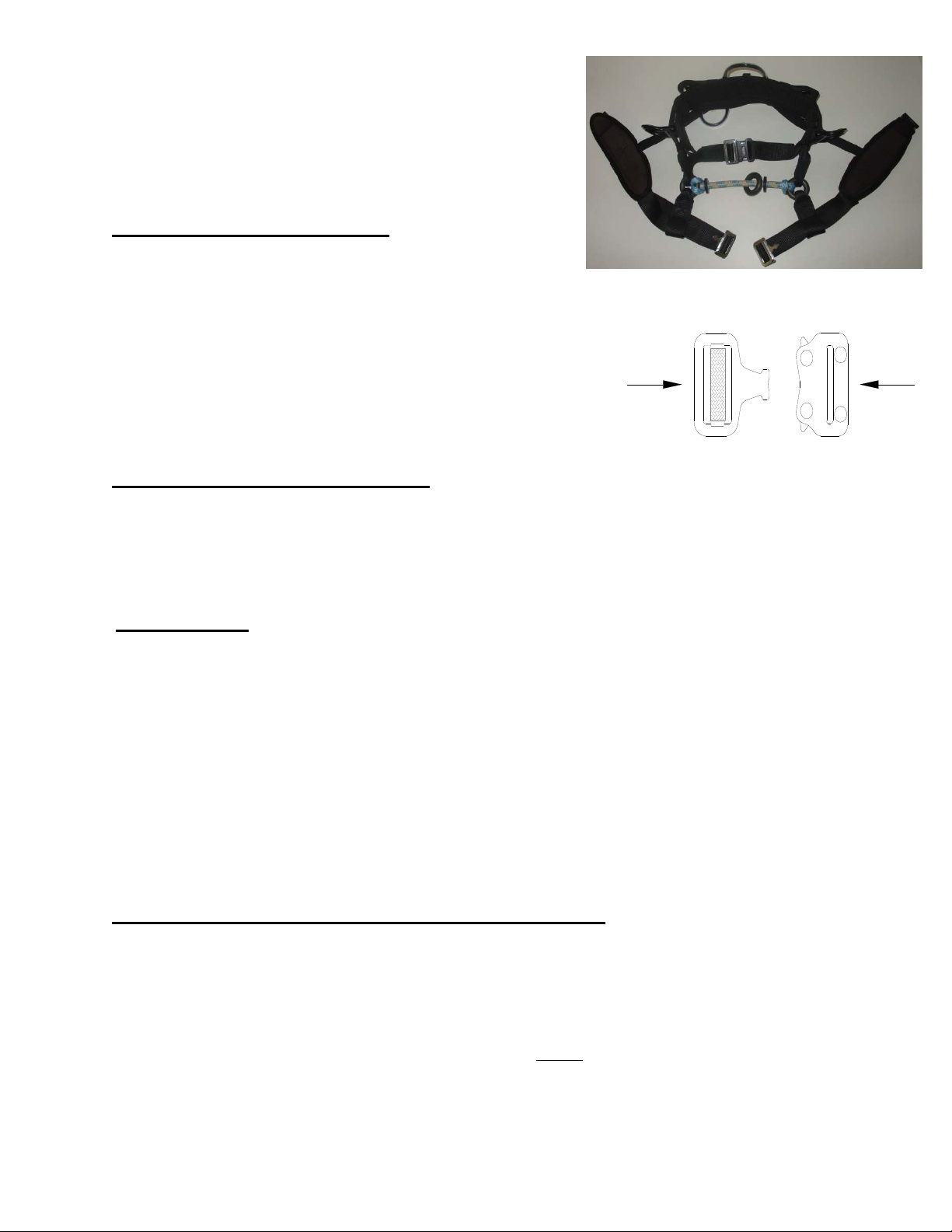

Buckingham Glide arborist saddles are intended for use as personal protection equipment only, not for towing or

hoisting and when properly used, comply with the requirements of ANSI Z133.1.

Do not use without proper training.

Before using the first time, the user should carry out a suspension test in a safe place to ensure that the equipment

is the correct size, has sufficient adjustment, and is of an acceptable comfort level for the intended use.

Before use of the equipment, consideration should be given as to how any necessary rescue could be safely

achieved.

This product is to be used for positioning and suspension only, NOT FOR FALL ARREST UNLESS USED WITH

OPTIONAL RETROFIT HARNESS. Therefore, it may be necessary to supplement arrangements for work

positioning / suspension with collective means (i.e. safety nets) or personal means of protection against falls from a

height (i.e. fall arrest system).

This equipment must only be used for the specific purpose for which it is designed and intended.

Destroy any and all equipment subjected to impact loading.

Never work without independent fall arrest protection if there is danger of a fall.

Keep equipment from coming into contact with sharp edges, extreme temperatures, excessive ultra violet rays,

and chemical agents. Exposure to these elements may have a detrimental effect on the integrity of the equipment.

Always visually check that all buckles are properly closed before use.

Attach only connecting devices meeting standards/regulations for intended use for positioning and suspension to

belt D-rings and attachment points.

Only positioning connection devices should be attached to side D-rings, as side D-rings are not intended for fall

arrest or suspension.

Position and / or adjust the work positioning lanyard in such a manner that the anchorage point is maintained at or

above waist level, the lanyard is kept taut, and free movement is restricted to a maximum of 1.96 ft. (0.6 m).

Positioning and suspension anchor points, as a minimum, must support user’s weight plus all additional job related

loads. Fall arrest anchor points must support a minimum of 5000 pounds per attached worker and be independent

of worker support.

As a minimum the materials used in the manufacture of this product are acceptable for use under all normal

environmental conditions tolerable to humans.

Always visually check that each snap hook freely engages D-ring, or anchor point, and keeper is completely

closed with each use. Never rely solely on the feel or sound of a snap hook engaging.

Before each use check that: 1) fabric or belt strap is free of burns, cuts, broken stitches, or excessive wear, 2)

rivets are not bent, loose, or missing, 3) buckles and D-rings are not distorted or cracked, 4) if there is a tongue

buckle, that the tongue does not bind on the buckle and buckle holes are not damaged. Always remove from

service, destroy, and discard a belt or harness if it fails inspection.

Always use locking snap hooks, or locking carabiners, as outlined in the ANSI Z133.1 standards for suspension,

work positioning, and fall arrest.

When in the work position, ensure there is no pressure on the snap hook locking mechanism sufficient to depress

it as this will, due to its length, render it incompatible with currently designed D-rings and make it very susceptible

to rollout.

During use, all fastening and adjusting elements must be regularly checked to ensure adjustment and closure.

Never attach multiple snap hooks to a D-ring unless they are of the locking type and designed for such

attachment.

Never disable locking keeper on a snap hook or carabiner.

Never punch additional holes in, or alter, any belt or harness in any way.

Product covered under these instructions / warnings should not be resold, redistributed, or re-used afteruse

by original user.

This equipment should be a personal issue to the employee using it.

GlideSeriesSaddles.pub (P/N 230168)

12/16/03 (Rev. 08/02/12)

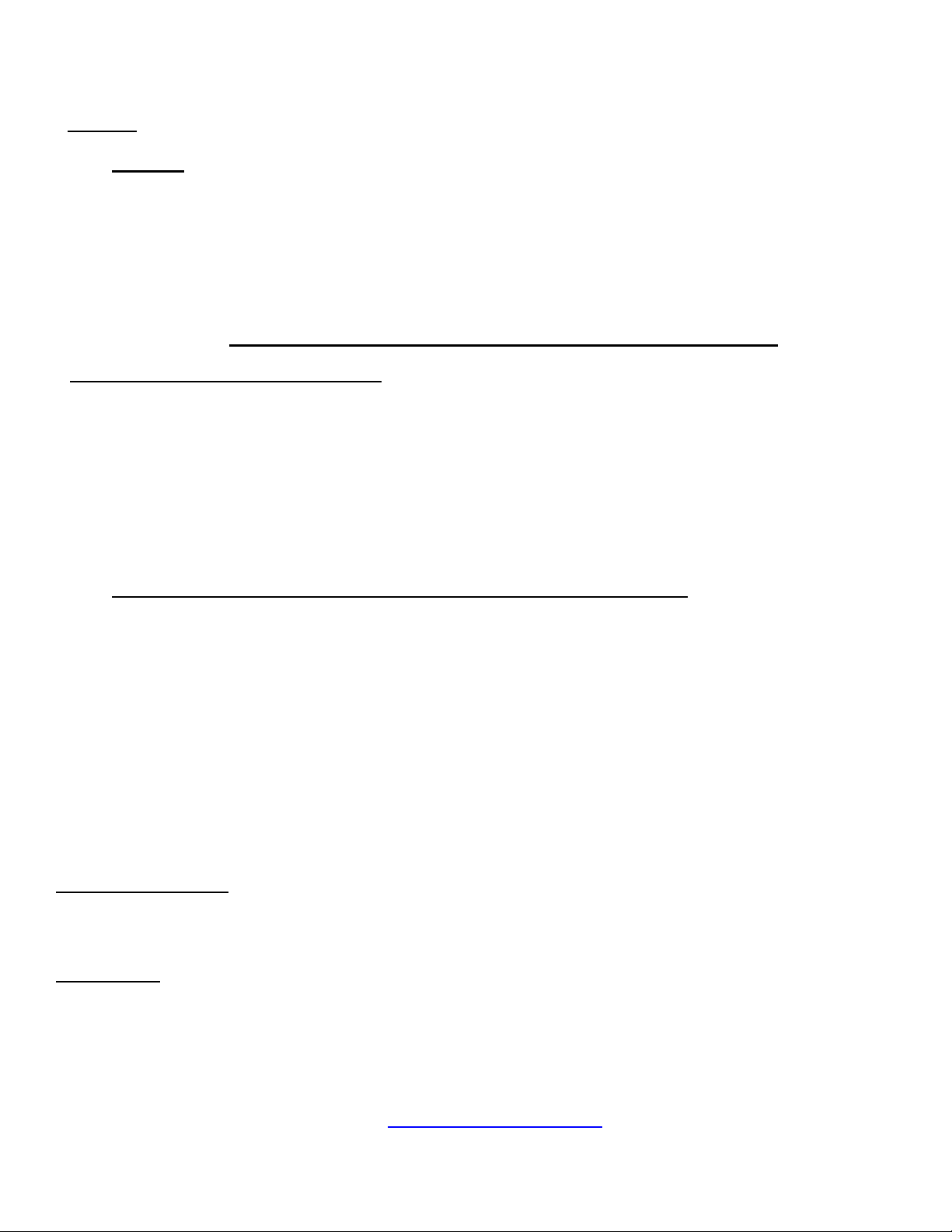

FRICTIONBCKL.dwg

Page 5