Key Code

The access to the installation level is protected against

unauthorized use by a key code. This will enable you

to change settings described in this manual.

This operating level should only be accessed by a

heating contractor or a trained operator.

Accessing the installation level.

Key Code 3

7

Key Code

• Press and release the “AUT” button. Button

is located adjacent to cover flap.

• Press and hold down the “INS”

button.

• Insert a pointed object into the hole

to the right of the “INS” button. Release

the “INS” button and remove the pointed

object from the hole.

• The control automatically

reverts back to previous operation if no

entries are made within 20 seconds.

• Different settings become accessible

by repeatedly pressing the “INS” button.

The display will indicate the current

setting. The value of each setting is

changed by turning the dial.

AMERICAN

INS O

SETTING THE LANGUAGE TO AMERICAN

• Enter the key code

• Turn dial until “American” appears.

• Automatic operation is resumed after

20 seconds.

2 Program Overview

6

Possible settings for the installation level.

The following settings allow the heating contractor to

customize the Ecomatic HS 2102 control for the

particular application.

1. Language:

Factory Setting: American

Other Languages: Deutsch, English,

Español, Italiano, etc.

2. Temperature Scale:

Factory Setting: Fahrenheit

Optional Selection: Celsius

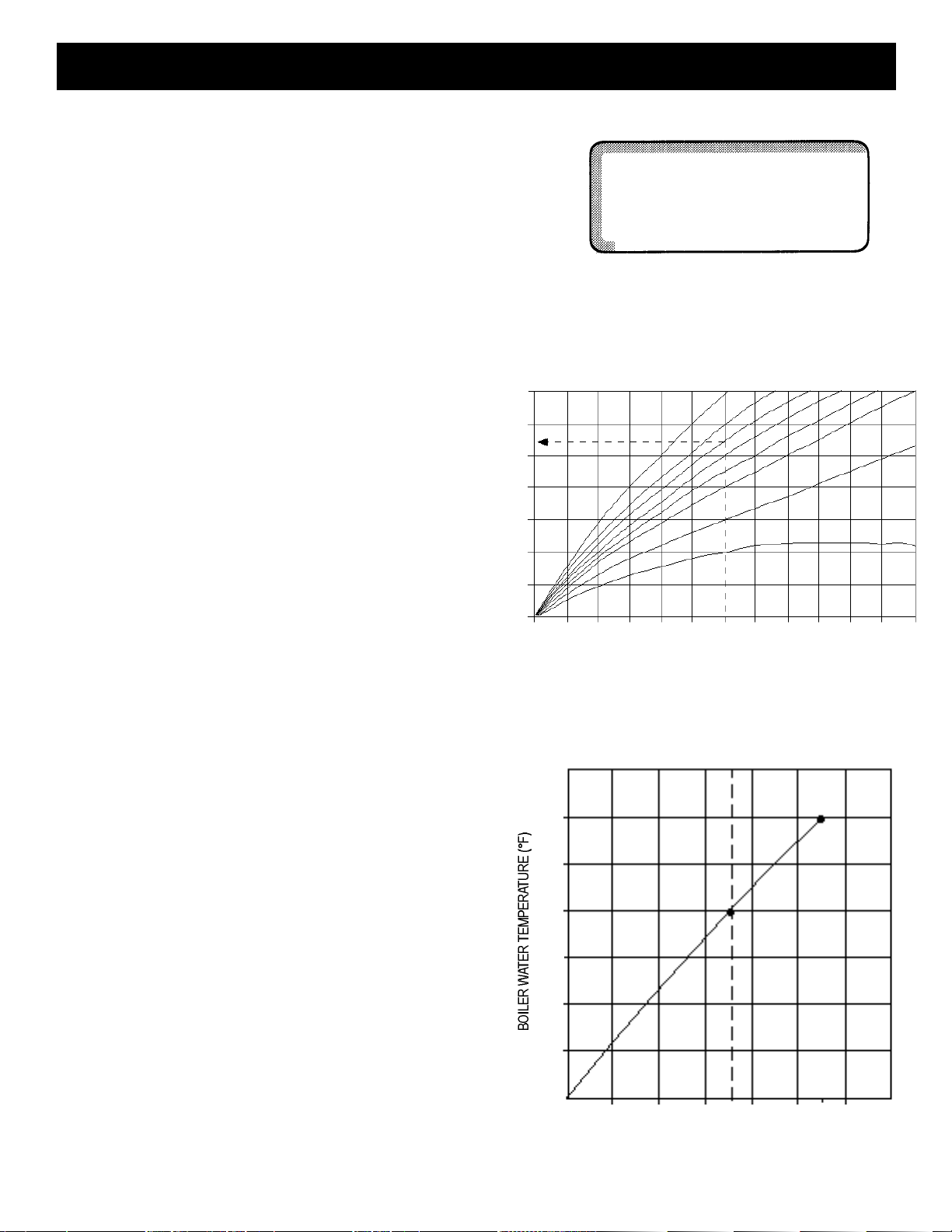

3. Heating curve-REF TEMP:

Factory Setting: 167°F (75˚ C)

Range: 122°F to 194°F (50°C to 90°C)

4. Freeze protection temperature-FREEZTEMP:

Factory Setting: 34°F (1°C)

Range: 14°F to 50°F (-10°C to 10°C)

5. Room Sensor - BFC:

Factory Setting: Off

Option: On

6. Compensation temperature-ROOM COMP:

(only with room sensor)

Factory Setting: 5°F (3°C)

Range: 0°F to 18°F (0°C to 10°C)

7. Setback modes:

Factory Setting: Outside Air Setback

Options: Setback

Room Setback

Boiler Off

8. Minimum boiler water temperature-MIN TEMP:

Factory Setting: 50°F (10°C)

Range: 50°F to 104°F (10°C to 40°C)

9. Maximum boiler water temperature-MAX TEMP:

Factory Setting: 185°F (85°C)

Range: 149°F to 194°F (65°C to 90°)

10. Flue Gas Sensor-FLUE GAS:

Factory Setting: Off

(Not available in the USA)

11. Clock recalibration-TIM ADJ:

Factory Setting: 0 Sec/Day

Range: -59 to 59 Sec/Day

12. Room temperature shift-OFFSET:

Factory Setting: 0

Range: -9°F to 9°F (-5°C to 5°C)

13. Diagnostic Test Features:

Relay Test

LCD Test

Heating curve display

Version number