Table of Contents

v

MA112680_39.3 [Original Instructions] 4/2014

IsoMet4000 Linear Precision Saw................................................................................................................1

Warranty........................................................................................................................................................ 1

Specifications................................................................................................................................................1

Safety Information.........................................................................................................................................2

Machine Use and Care...........................................................................................................................2

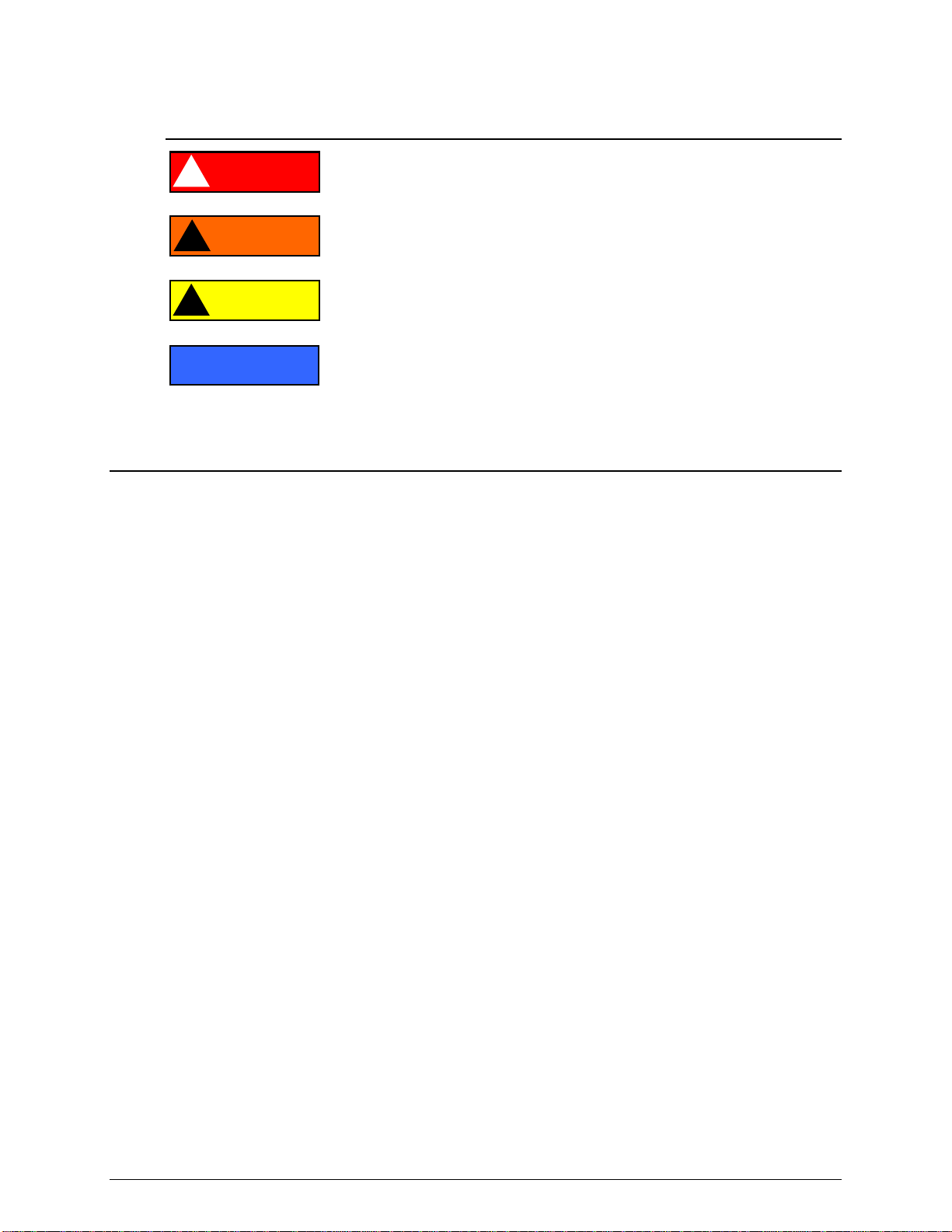

Safety Terms .......................................................................................................................................... 3

Unpacking .....................................................................................................................................................3

Installation.....................................................................................................................................................4

Electrical Installation .....................................................................................................................................4

Blade Installation...........................................................................................................................................5

Installing a Blade..............................................................................................................................5

Cooling and Lubrication ................................................................................................................................6

Vises.............................................................................................................................................................. 6

External Recirculating System......................................................................................................................7

IsoMet 4000 Controls and Functions ............................................................................................................8

Front Panel Controls............................................................................................................................... 8

IsoMet 4000 Display Screens and Commands...........................................................................................10

Parameter Fields ..................................................................................................................................10

L1 Display Screen.................................................................................................................................11

L1 Display Screen Commands ......................................................................................................11

Pause CUTTING CYCLE...............................................................................................................11

L2 Display Screen.................................................................................................................................12

L2 Display Screen Commands ......................................................................................................12

L3 Display Screen.................................................................................................................................13

L3 Display Screen Commands ......................................................................................................13

Specimen Positioning..................................................................................................................................14

Specimen Loading................................................................................................................................14

Positioning a Specimen with an Unknown Thickness..........................................................................14

Positioning a Specimen with a Known Thickness................................................................................16

Operation.....................................................................................................................................................17

Cutting a Specimen ..............................................................................................................................17

Single Cut.............................................................................................................................................17

Manual Cutting......................................................................................................................................18

SMART CUT: Checking and Adjusting the Feed Rate ...............................................................................19

Blade Dressing............................................................................................................................................19

Dressing the Blade ...............................................................................................................................20

Automatic Blade Dressing, Rotating Chuck, and Specimen Positioning System.......................................21

Removing the Specimen Position System (Catalog Number 11-2699).........................................21

Installing the Specimen Position System.......................................................................................22

Removing the Rotating Chuck (Catalog Number 11-2695) ...........................................................22

Installing the Rotating Chuck.........................................................................................................22

Removing the Automatic Blade Dressing System (Catalog Number 11-2696).............................22

Installing the Automatic Blade Dressing System ...........................................................................23

Warning Messages .....................................................................................................................................24