6

III. Installation Guide

A. Installation Requirements

1. Only qualified and/or authorized persons must carry out the installation, gas conversion, and

servicing/repair of this equipment.

2. Components having adjustments protected by the manufacturer are not to be adjusted by the

installation person. They must only be adjusted by an authorized Service Engineer.

3. This equipment must be installed in an area with sufficient ventilation to prevent the occurrence

of unacceptable concentrations of substances harmful to health.

4. The installation of this equipment must comply with the local gas, health, and safety

requirements.

5. The warranty will be void if this equipment was not installed in accordance with the

manufacturer’s specification and relevant National and Local codes.

6. This equipment must be installed in accordance with relevant National Installation codes, and in

addition, in accordance with relevant National and Local codes covering gas and fire safety.

Australia:

AS 5601/AG 601 (to be AS 5601)- Gas Installations

New Zealand:

NZS 5261 - Gas Installation.

United Kingdom:

Gas Safety (Installation and Use) Regulations 1998

BS 6173-Installation of Catering Appliances.

BS 5440-1&2 Installation Flueing & Ventilation.

Ireland:

IS 820-Non Domestic Gas Installations.

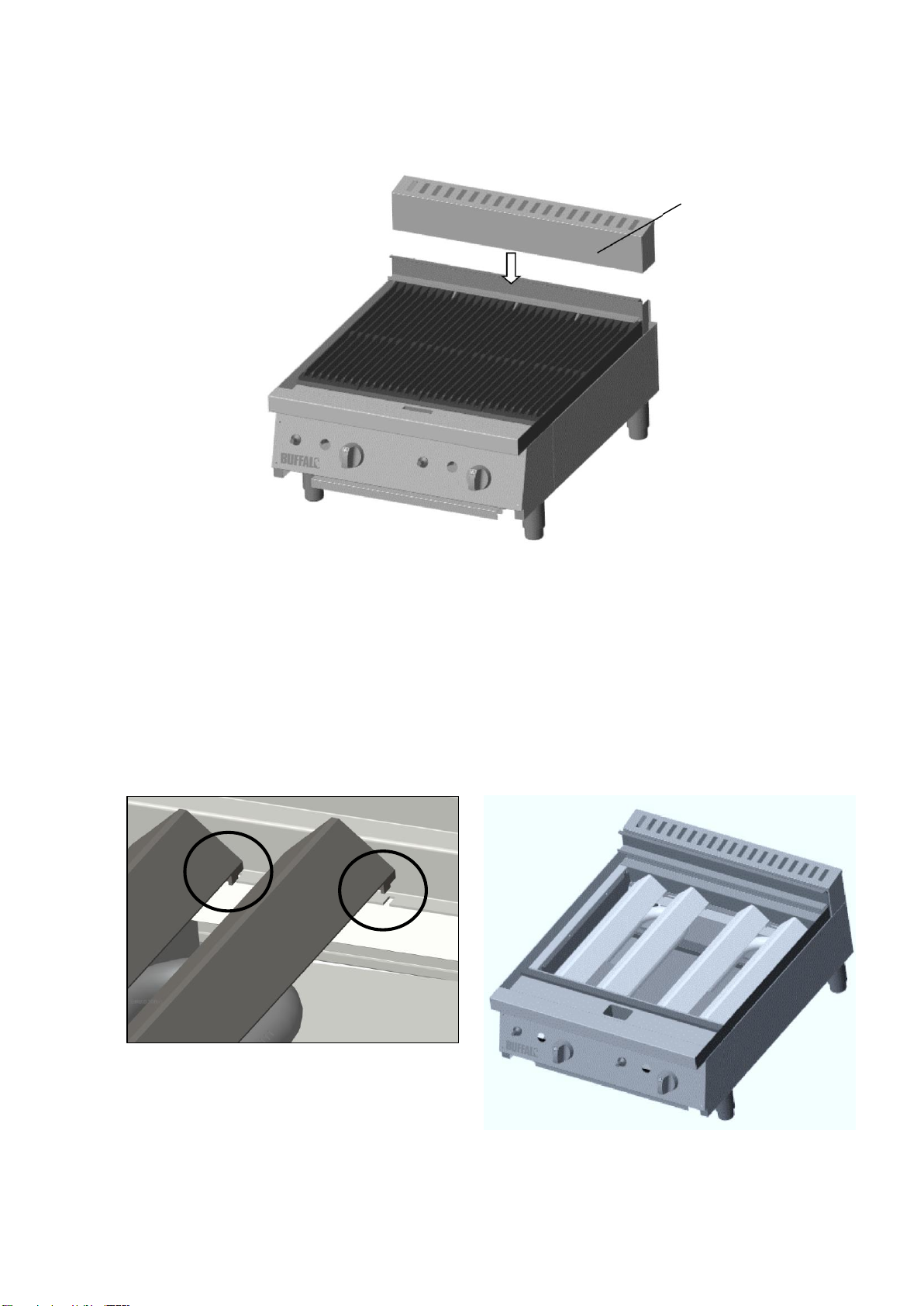

B. Unpack the equipment

1. Remove all packaging and transit protection from the appliance including all protective film

coating from the exterior stainless steel panels. NOTE: Take caution when unpacking the

equipment, as wood pallets or skids can contain splinters and nails. Shipping cartons can contain

large staples. Ensure to wear cut-resistant gloves and protective eyewear during unpacking,

opening, removing and disposing of shipping containers.

2. Upon opening the package, check immediately the equipment and accessories/parts for any

damage or deficiency.

3. Upon checking of the unit, report immediately to the carrier and the distributor, for any damage

or deficiency on the equipment, and its accessories or parts.

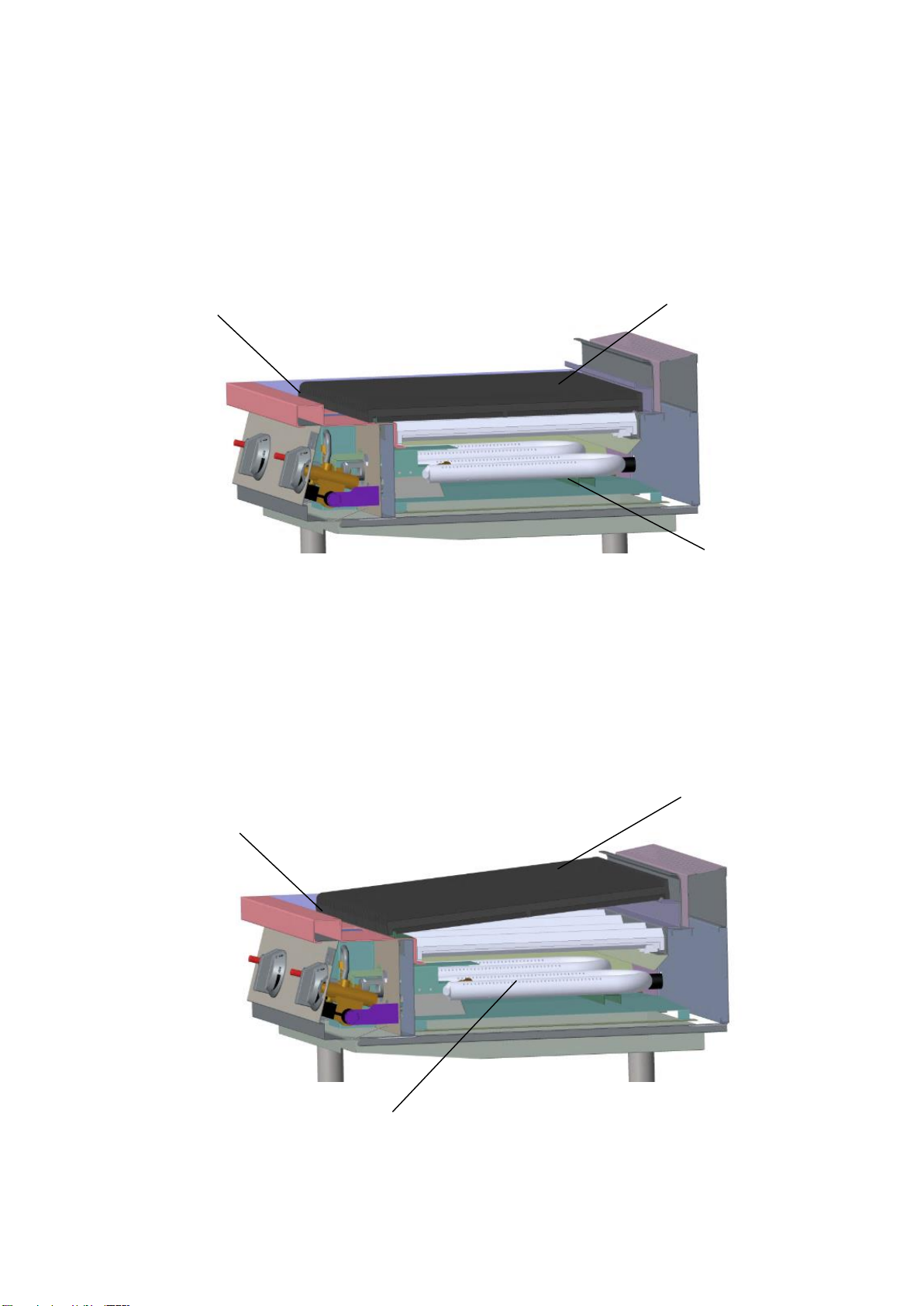

C. Establish the operational location of the equipment

1. This equipment must be installed in an area with sufficient ventilation to prevent the occurrence

of unacceptable concentrations of substances harmful to health.

2. Install the equipment in an area which provides enough airflow for combustion.

3. All air for burner combustion is supplied from underneath the unit. The feet/stands must always

be fitted and no obstruction must be placed on the underside or around the base of the unit, as

obstruction will cause incorrect operation and/or failure of the appliance.

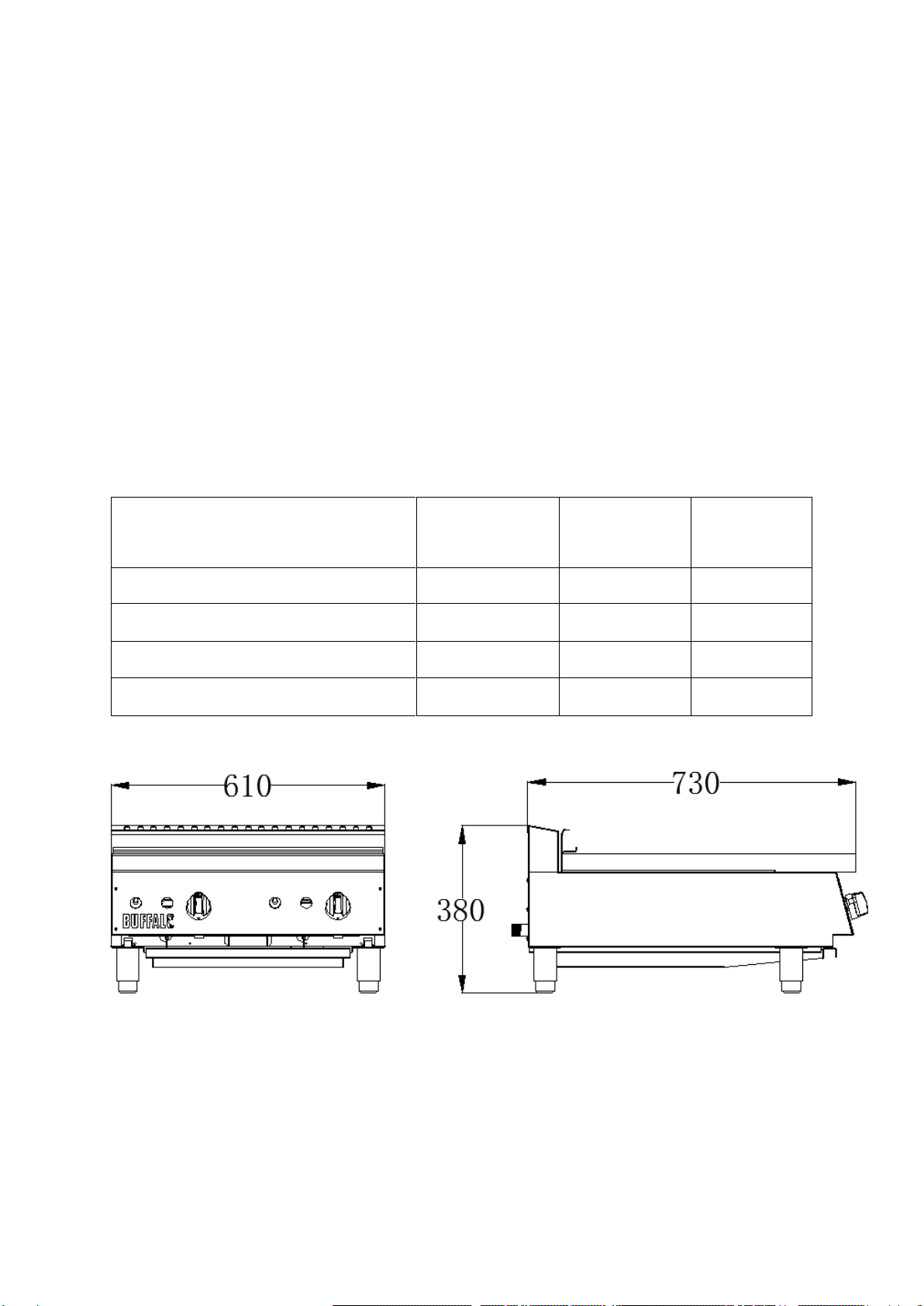

4. Position the appliance in its approximate working location, then install the feet or gas stand

provided.