4

2. Safe Operating Instructions

1. The operator must wear slip-resistant safety shoes, suitable clothing, safety glasses,

helmet, and earplugs.

2. While operating the machine, please keep well balanced; the user shall stand in front of

Air Filter to operate the machine. While operating the machine, do not partake in any other

activity.

3. While operating the machine always use both hands.

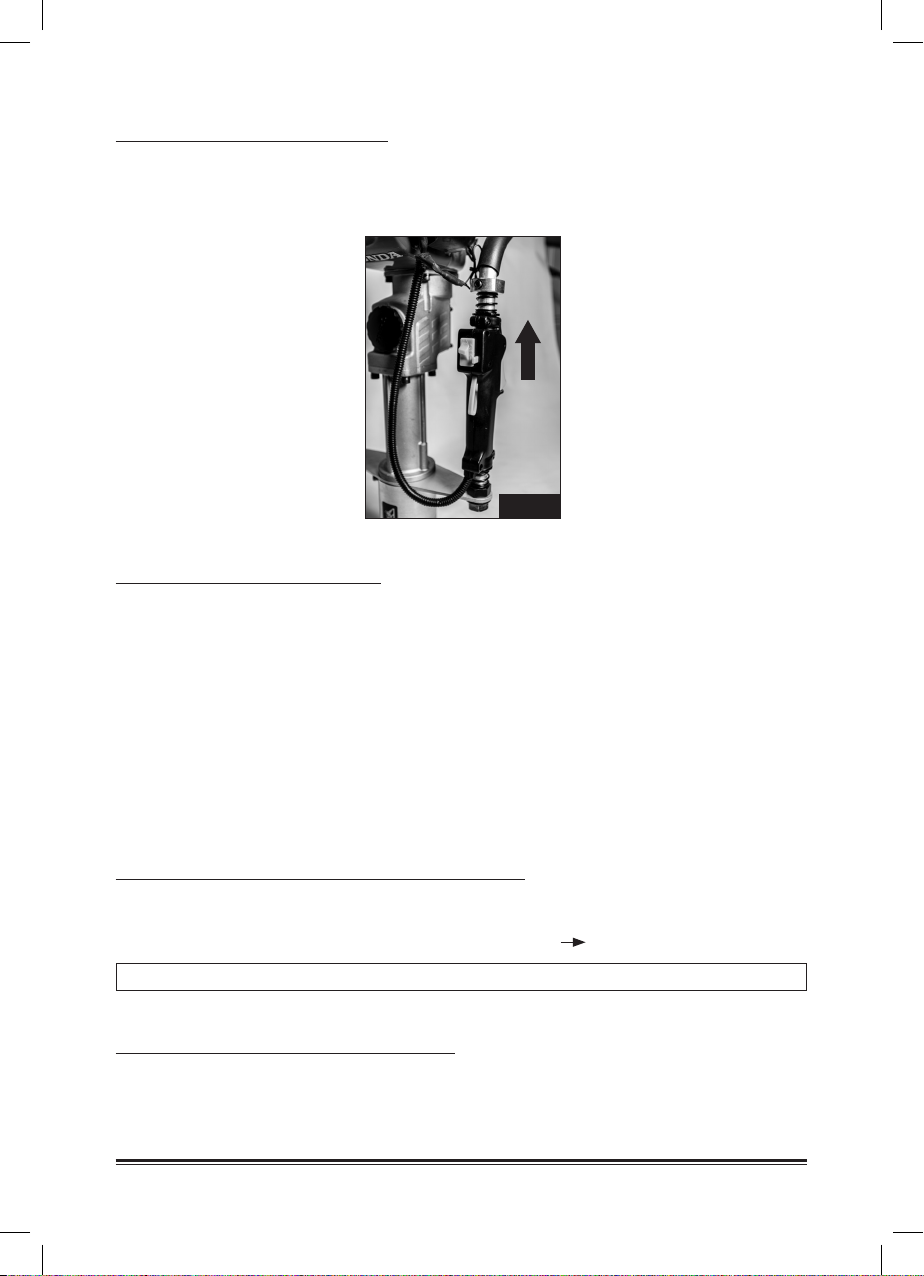

4. When lifting the machine always have engine at idle.

5. Keep any observer away from the operation area to avoid injury.

6. Select the medium speed to operate post driver.

7. Keep the handle dry and clean free of oil or fuel.

8. If operation is stopped midway; be sure to turn o the engine.

9. Pre-check before use that all bolts and screws are tight and that they have not vibrated

loose from the previous day’s work or transportation.

10. Gasoline is highly ammable. Therefore, replenish fuel in a well-ventilated environment.

During fuel lling, engine must be turned o.

11. Do not add too much fuel and do not exceed the neck of the fuel tank. If fuel spills, wait

until the fuel vaporizes completely and then start the engine.

12. After refueling, tighten the fuel tank lid. If fuel spills while operating the machine, check

that the fuel tank lid is tight and check for damage to the fuel tank. If there is a fuel leak

shut the machine down immediately.

13. Keep reserve fuel in a safe storage area away from re or open ame.

14. Where the post driver is used in closed areas such as tunnels, trenches and conned

spaces, ensure there is ample air circulation to avoid waste gas poisoning and suocation.

15. When transporting ensure machine is tied down securely so as to not damage the

machine.

16. Before transport, empty fuel inside fuel tank to avoid leakage.

17. Do not allow non-qualied personnel to dismantle the post driver. This will avoid internal

damage of the machine, shortened service life of the post driver or accidents. To do so will

void the warranty.

3. Main Purpose and Function

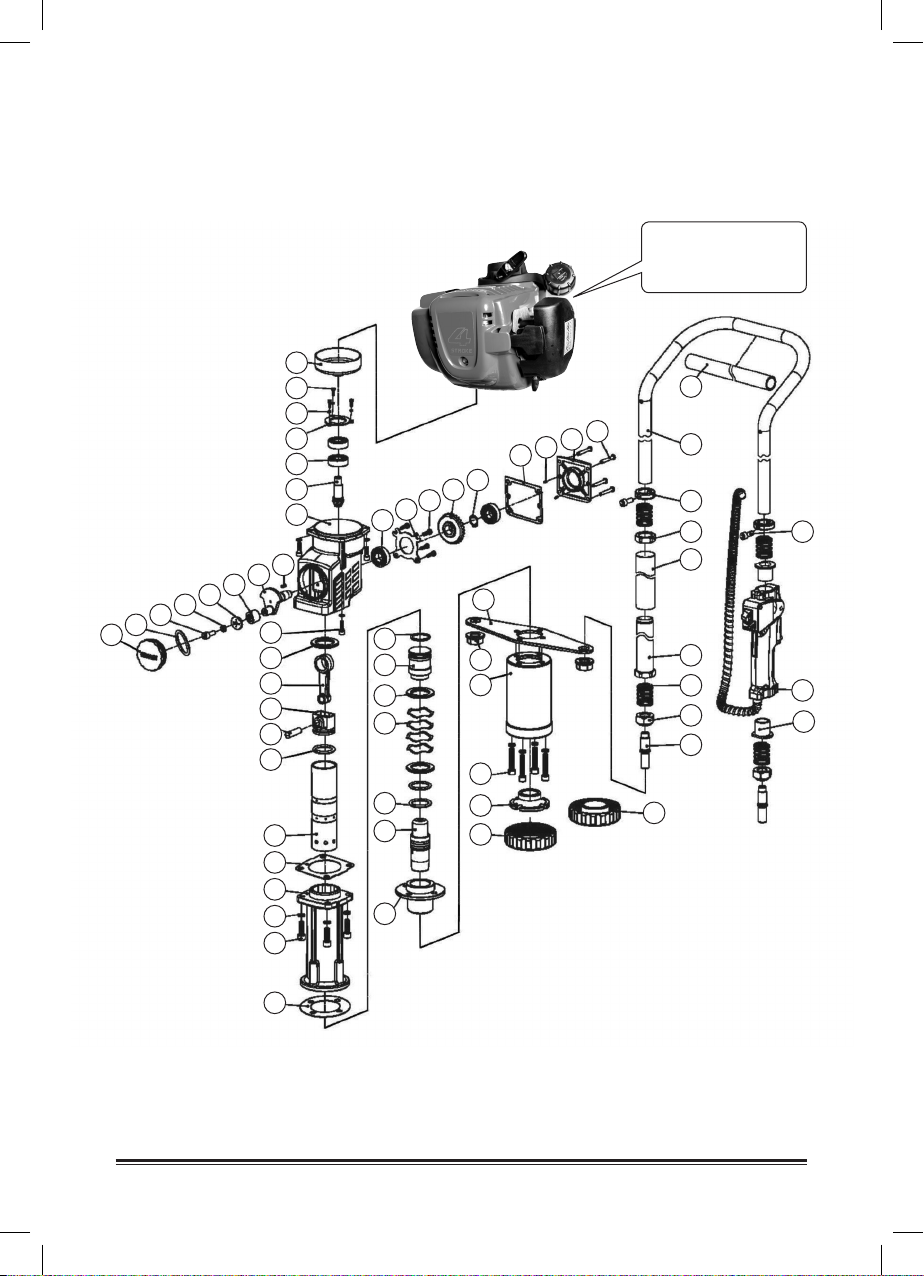

3.1 Purpose: It can be used for driving in star pickets, pipe, form work pins for use on fences,

barriers and construction.

3.2 Function

3.2.1 It is a handheld gasoline post driver that is light weight and produces low emissions.

3.2.2 The product is an excellent design and engineered to be easy to use with minimal eort

and powerful operating eciency. The operator can achieve 360° all-round operation.

3.2.3 It can regulate impact energy and impact frequency and be applied to a variety of posts

with diameter larger than 20mm (inclusive) and smaller less than 80mm (inclusive).

3.2.4 Advantage: Saves the trouble of using heavy machines such as generator, air compressor,

hoses, leads and vehicle.

3.2.5 The operating handle of the machine is rubber and plastic sponge which can greatly

reduce the recoil force of the machine. It features a two-way Dampening Spring which

makes it more comfortable to use.