ne-cut-manual-e Page 6 / 10

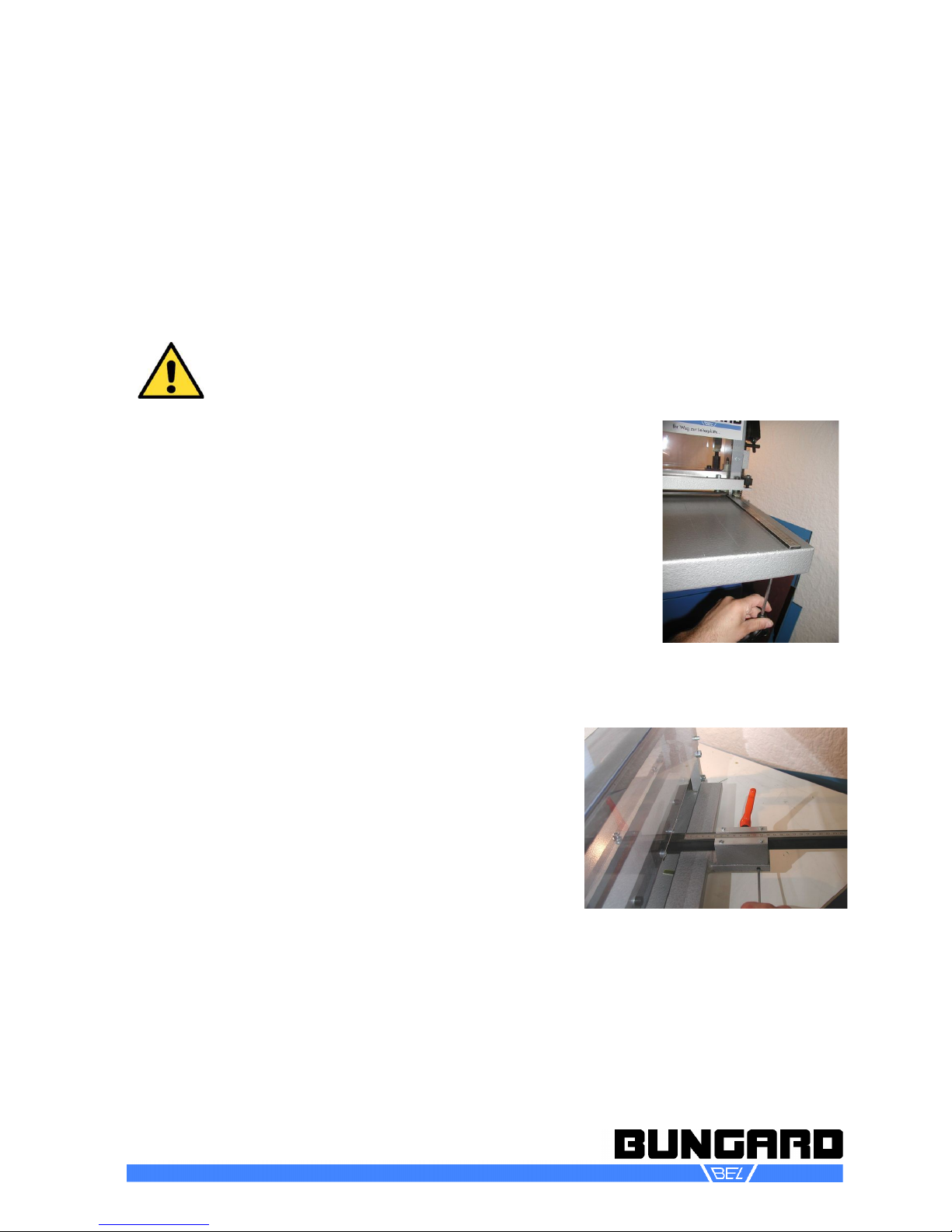

Turn the lever up and back to its home position. Take a wide board and scoop it first against the front side

counter bar and then against the rear counter bare.

Pull the lever until the clamping unit fixes the board. In this position you can adjust the height of the rear

counter bar until it lies smooth against the board. Now tighten the Allen key screws.

The parallelity of the rear counter bare was pre-adjusted and proved before the machine left the company.

However it happens sometimes that the rear counter bare does not fit after disassembly. The reason for

this could be a an unevenness of the finishing coat. If you happen to notice a disparallelity after some test

cuts, please read chapter adjustment how to scale the counter bare again.

Operating

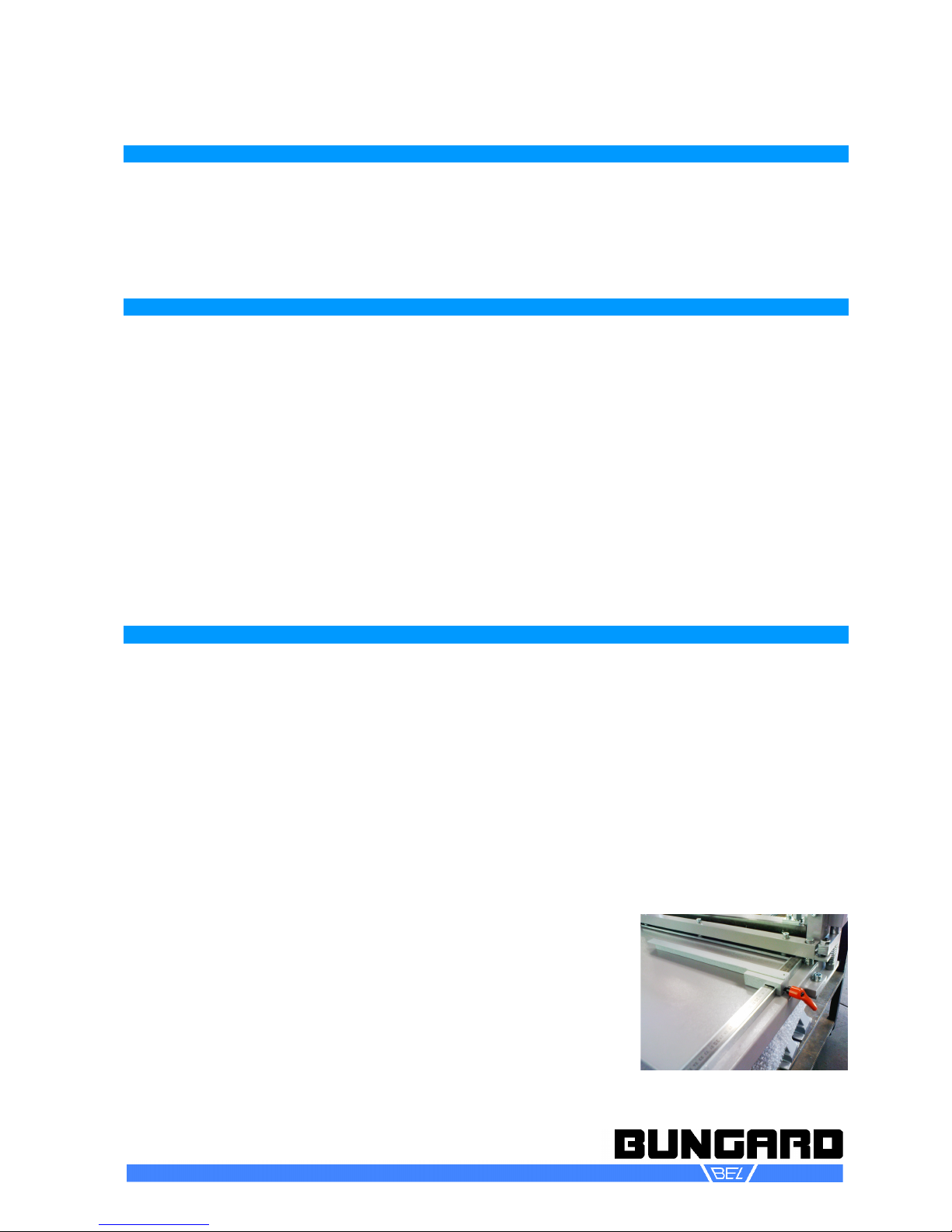

Adjust the size of the board to be cut with the rear counter bare: Loosen the orange knob by lifting and

turning. Slide the counter bare to the rough dimension of the board, tighten the knob a little bit and adjust

the zero position mark precisely by knocking against the skid of the counter bare. Then tight the knob

firmly. Place the board against the front counter bare and push it against the rear counter bare.

Pull the lever to the front and down. The downholder (clamping unit) will clamp the board and then the

blade will cut it. Pull the lever all the way back, so the clamping unit releases the board.

If you place the board precisely to the scale of the front counter bare, you can even perform some cuts

without adjusting the rear counter bare. Or you can trim the rims of the board by sight. If you work without

the rear counter bare, it can happen that the board is pushed back by the blade for about 0,1-0,2 mm.

That is a general side effect of the cutting procedure and no defect of the machine. To reduce this effect

we offer as an option a front parallel counter bare.

Please make sure to take out regularly the cuts and the oddments from the ground plate of the machine. If

the oddments are very small, they might stick underneath the blade. Attention: risk of injury! Lower the

upper blade until the gap between upper and lower blade is closed before you remove these small parts.

Disassem ly

ismount the rear counter bar only for transport reason, because

you have to go through the adjustment procedure again after you

mount the counter bare . This procedure is described in the chapters

Set Up and Adjustment. The counter bare itself can be slid off the

beam after the knob is loose.

For safety reasons always keep the clamping unit in its position.

Nevertheless you can remove the clamping unit by pressing it down

on the side till it comes free from the press beams which connect the

clamping unit with the lowering mechanism.

Turn away the press beams and lift the clamping unit.

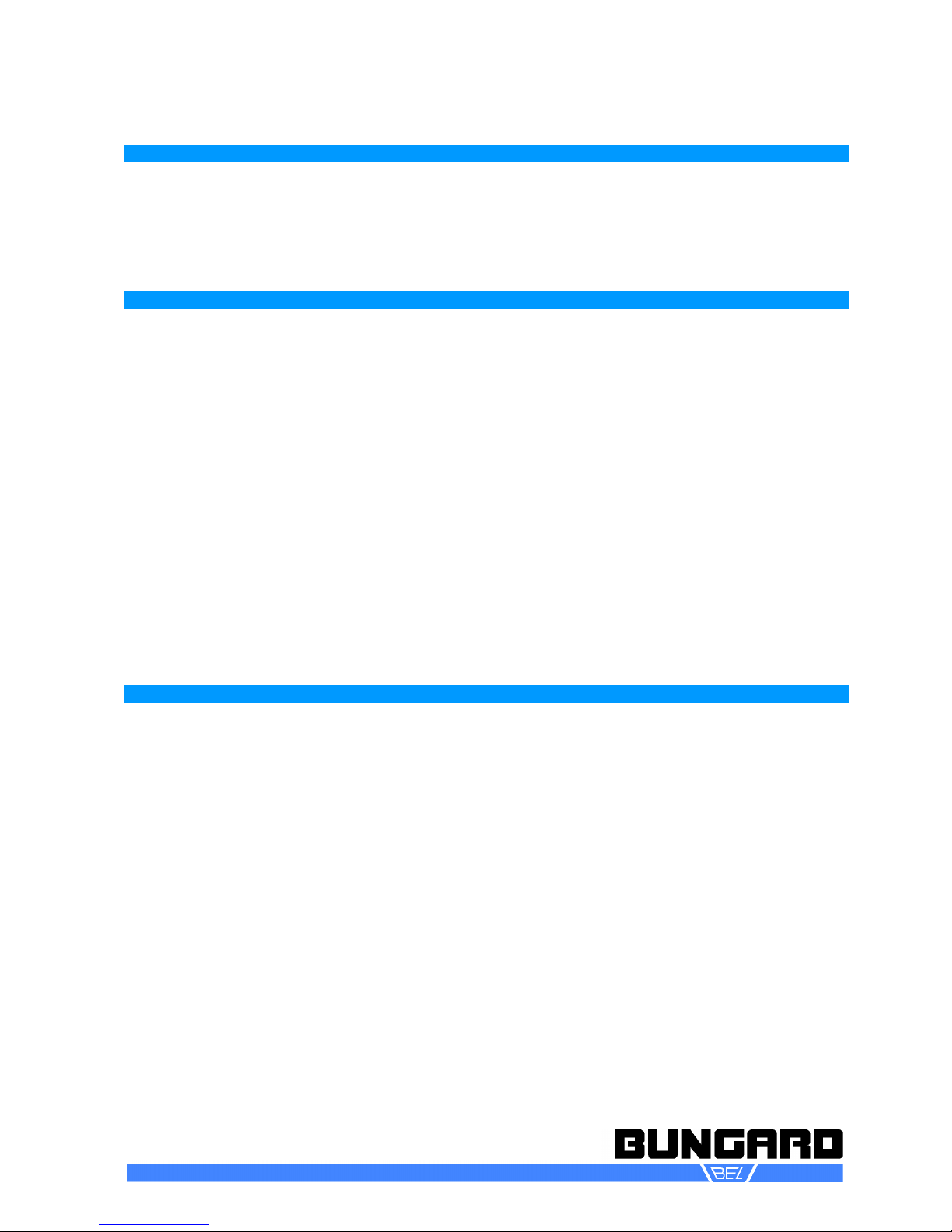

If you need to have access to the lower blade you must remove the

machine table. Loosen the two screws which connect the table to the

ground plate (Picture 5). After remounting the table you have to con-

trol the perpendicularity of the table and if needed, readjust the scale

of the front counter bare (see chapter adjustment).