RLM419p-Manual-E Page 9 / 13

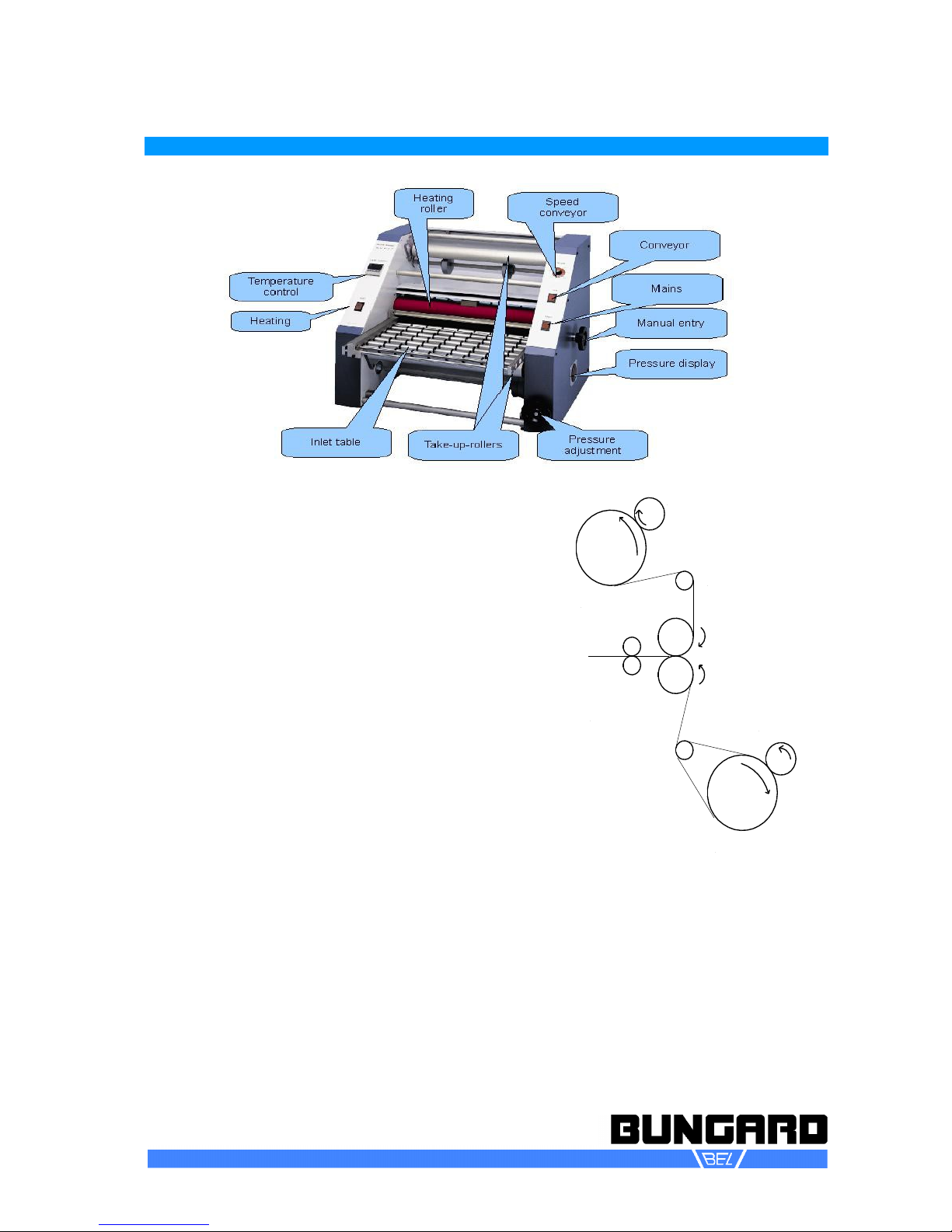

Put the take up roller back in its place on top of the laminate roller

and fix the separation foil to the take up roller by adhesive tape. Re-

peat this procedure for the upper coil with reference to the thread-

ing diagram (9). Make sure the take-up rollers are driven automatic-

ally by the rotation of the laminate coil.

For the following step you will profit from two pieces of cardboard of approx. 300 x 300 size and 1 to

2 mm thickness.

Turn the laminator main supply on.

Leave the heater and drive switch off.

Let the top laminate hang loosely over

the rollers. The protective foil faces to

the heating rollers the sticky photo

polymer faces to the operator. Take

the lower laminate and press it in

proper alignment against the top lam-

inate.

The laminate may not be sloppy or

wrinkled. You will find the wrinkles on

your board again. Now take a card-

board of 30 x 30 cm and 1 mm thick-

ness. Push it against the laminate and

further between the heating rollers (in

opposite to a pcb a cardboard is soft

and will not permanently deform the heating rollers).

Turn the hand wheel and thus promote the cardboard until you feel a firm resistance. This is the

point where the board is due to enter between the transport rollers. The transport rollers can be

seen from the back of the laminator. Set a speed of 0.5 on the scale and turn on the transport. Keep

tension on the hand wheel until you feel that the transport rollers grab the cardboard.

Stop the transport before the cardboard disappears completely between the heating rollers. Check

that upper and lower laminate run congruent. If necessary loosen alternately the left and right upper

flange and move these rollers till the laminate aligns properly.

If the laminate shows wrinkles after having shifted the flanges please insert the cardboard one

more time to enable the laminate to level out.

The loaded laminate will look like in picture (10):

Finally mount the inlet roller table: Lift it at its rear insert the front end in the middle of the unit until

it goes into the two lateral pins on the housing and lower the rear end until this snaps onto the pins

as well.

It is assumed that at the end of each job you leave a piece of cardboard between the lamination

rollers. This serves to keep the lamination rollers clean from molten laminate.

Laminating

Now you can start operating the machine:

Turn the heaters on. Set the desired temperature and wait until the unit has heated up. Set the pres-

sure and speed and start the transport. Let the cardboard leave the lamination rollers. Insert a PC

board through the brushes of the inlet table and push it slightly until it is taken by the lamination

rollers. If you do several PCBs at a time feed them one after the other with about 2 cm distance

between them.