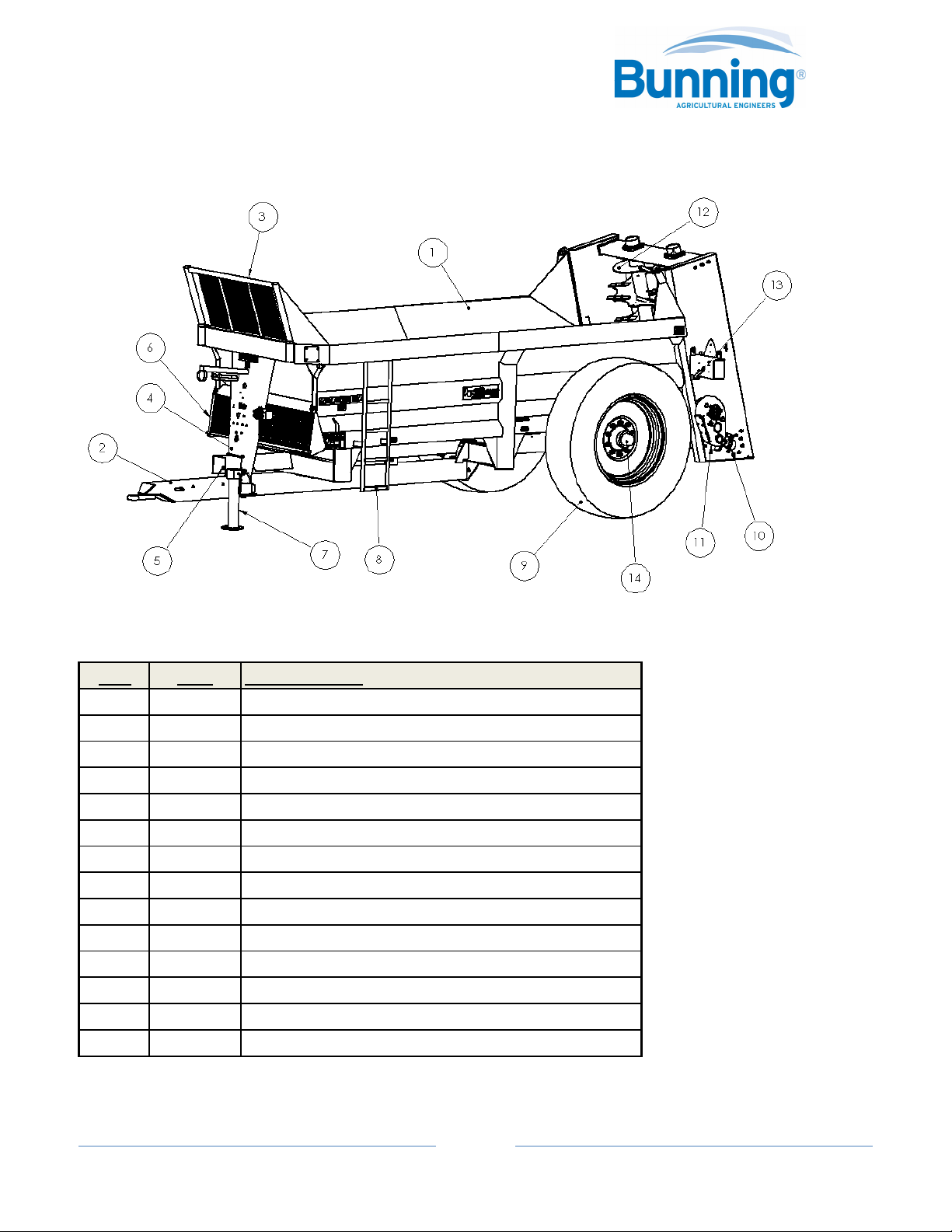

LOPRO670&780MANURESPREADER–INSTRUCTION&SPARESMANUAL

Page3

CHASSISSERIALNUMBER................................................................................

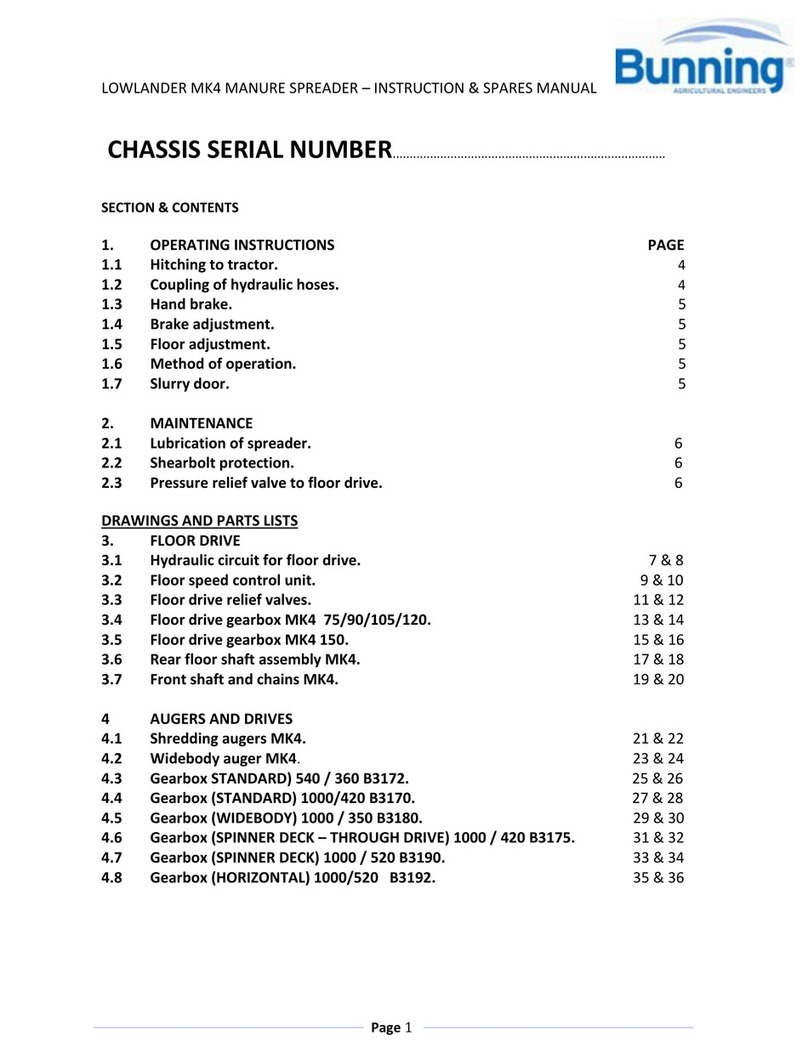

SECTION&CONTENTSPAGE

Preface5

Howtousethismanual 5

Operatingonpublicroads 5

Introduction 6

Disposal6

ECDeclarationofConformity 7

Machineoverview8

1. OPERATINGINSTRUCTIONS

1.1 Hitchingtotractor. 9

1.2 Couplingofhydraulichoses.10

1.3 Flooradjustment. 11

1.4 Methodofoperation. 11

1.5SlurryDoor.11

2.MAINTENANCE

2.1 Lubricationofspreader. 12

2.2 Servicingintervals. 12

2.3 Amountofoilrequiredtofillgearboxes. 15

2.4Servicerecord16

2.5 Shearboltprotection. 17

2.6Greasepoints17

2.7Tire&Wheel18

2.8PTOInspection19

3. DRAWINGS&PARTSLISTS

3.1 FloorDriveAssembly 21

3.2 FrontShaft&Chains 27

3.3 Augers&Gearboxes 28

3.4PTOShafts33

3.5SlurryDoor38

3.6Drawbar40

3.7AxleAssembly41

3.8LampCovers44

3.9 DetachableSpinnerDeck 46

3.10BodySeals47

3.11WeighBars47

3.12Lighting48