3

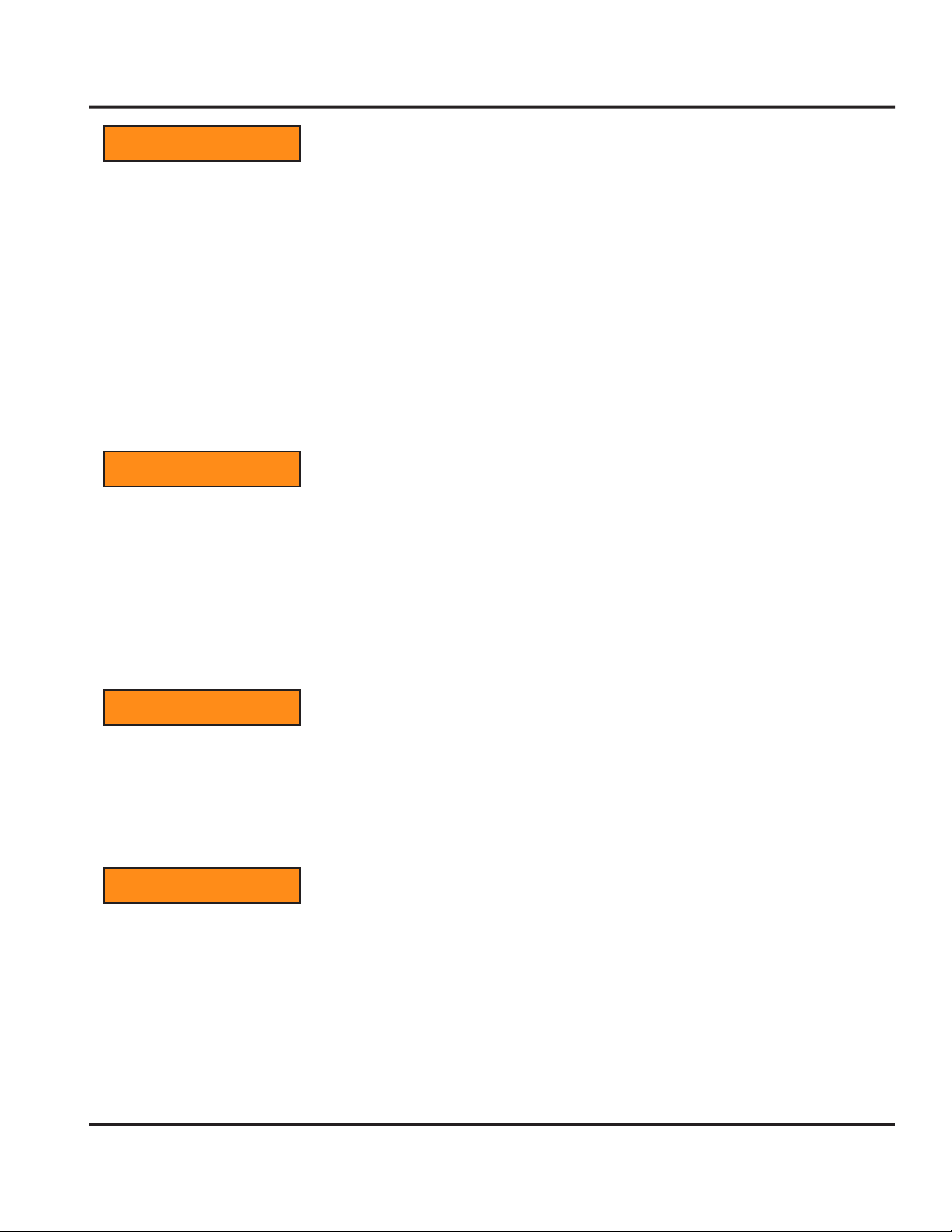

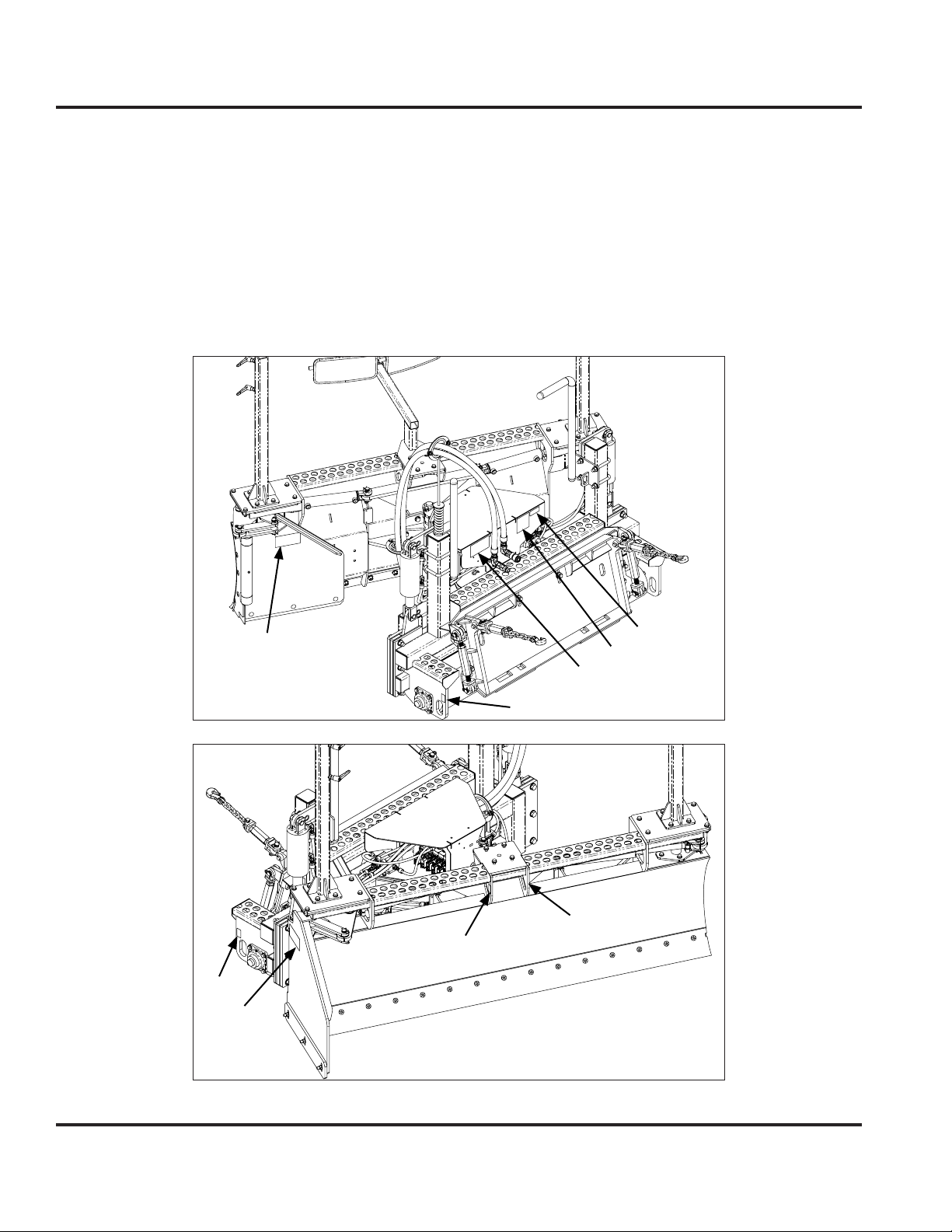

Laser Grader

1. Introduction

Congratulations on your purchase of your Burchland Manufacturing Grader.

Carefully examine the grader upon receipt. Report any damage immediately to the freight carrier and register

any claim.

Read and understand this manual before using the grader and follow all of the safety instructions. Keep this

manual with the grader at all times.

Information provided in this manual was current as of the issue date. Burchland Manufacturing, Inc. reserves

the right to make design changes without further notice or liability.

This manual explains the operation and routine maintenance of the LGX Laser Grader.

Information furnished in this manual does not include all of the details of design, production, or variations of

the equipment. It does not cover all the possible contingencies, which may arise during operation, setup, or

maintenance. Should special issues arise, or further information be desired, please contact your Burchland

Manufacturing dealer.

The text contained in this manual is for current production models. Some instructions and maintenance

procedures may not apply to your specic unit.

Equipment modications from original design and specications are strictly prohibited. Modications or

overloading may compromise safe operation of the grader, subjecting users to serious injury or death and

may void any remaining warranty.

Burchland Manufacturing reserves the right to change, improve, modify or expand features of this equipment

at any time. Specications, models, or equipment are subject to change without notice, and without incurring

any obligations to change, improve or expand features of previously delivered equipment. Because of the

variations in optional equipment and continued design improvement, certain information contained within

this manual may not apply.

This operators manual does not replace, nor does its use release the owner/operator from observing all

safety codes or operating limitations as well as any applicable federal, state, provincial or local regulations.

The grader is designed to be used by experienced operators, trained in the safe operation of a skidsteer and

trained in the hazards related to using the grader and the safe use of the grader for the intended purpose.

Serious injury or death of the operator or bystanders may be caused if the grader is misused. Misuse may

also cause damage to the skidsteer carrying the grader, or the grader itself.

Introduction