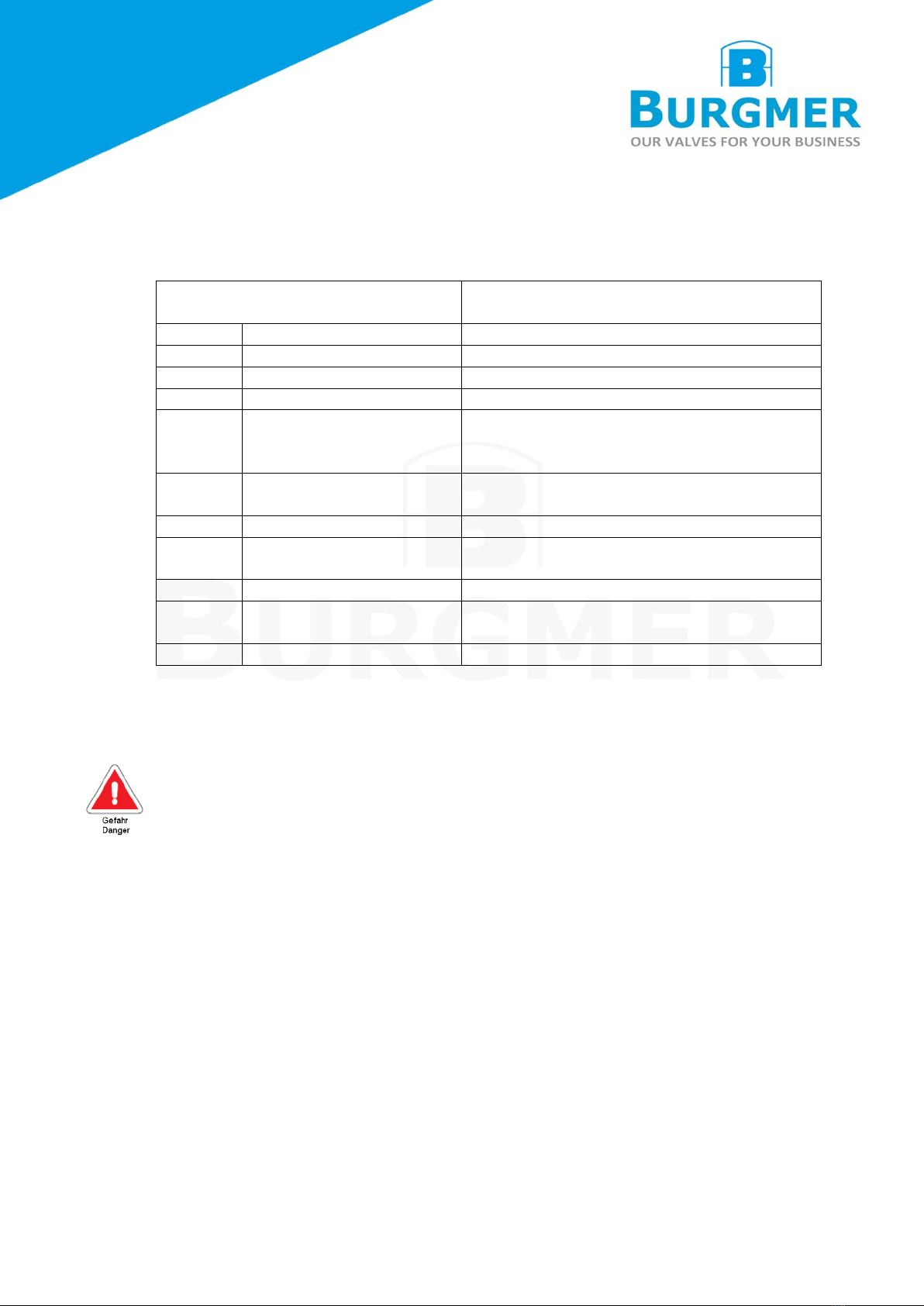

BWM DBS-E/DBS/F-EP U/F-DK page [10] state: 01.2018

6.1 Assembly

BURGMER gate valves are to be installed or attached between or to flanges, according to EN

1092-1 and DIN EN 1759-1, with sealing bars of shapes B1 or B2, which are plane parallel

machined and have to align. Other types of flanges and sealing bars may only be used after

the manufacturer has checked their technical viability.

The seal faces of body and counter flanges must be smooth and clean.

In BA and collar II seals, the sealing insert acts at the same time as flange seal. Please make

sure to use counter flanges with diameters suited to support the seals of the gate valves.

The inner diameter of the counter flanges is intended to cover at least 2/3 of the seal face

and at most the clear width of the valve.

Don’t use additional flange for this type of sealing.

ATTENTION! In case of use as end valve, the seal face located on the outside has to be

supported by a suitable through flange. Moreover, in normal operation, especially in case

of hot, gaseous and/or hazardous media, a blind flange must be installed or the valve

bolted safely in the position (“CLOSED”).

It is forbidden to weld the flanges to the system or other pipeline/conveyor parts after the

gate valve is installed (seal insert can burn!).

INSTALLATION INSTRUCTIONS!

•Check the gate valves for transportation damages. Don’t install the valves if it’s

damaged.

•Make sure to install only gate valves, which technical specifications (permitted

pressure, temperature class, etc.) fulfil the installation requirements.

•The gate valve must be mounted that no big forces may absorb through the casing.

The bulk material must enter the gate valve vertically!

•The gate valves can be installed in a position with regard to the medium flow direction

(marked with a red arrow on the casing).

•The valve may not serve as fixed point; it is supported by the pipeline system.

•Please ensure to insert the gate valves centred between the counter flanges.

•Huge and heavy actuators must be stabilized.

•Clean the flange faces and install flange seals appropriate to the quality of the valve

seal. (IMPORTANT!see also item 6.1.)

•If the valves are provided with grounding screws, shaft and body of the valve must

be integrated mandatorily into the potential equalisation of the whole system. Shaft

and body are provided for this with a specially marked threaded hole. The grounding

cable must have then a cross section of at least 4mm² for nominal widths 50-350

Furthermore, the 90° rotational movement of the shaft is to be taken into account

when dimensioning the length of the shaft grounding cable!

•Thermal expansions in the system are to be compensated through compensators.