Page 2 of 20

Table of Contents

Technical data................................................................................................................................4

Stove Dimensions..........................................................................................................................5

9507.................................................................................................................................................5

9510...................................................................................................................................................

.........................................................................................................................................................6

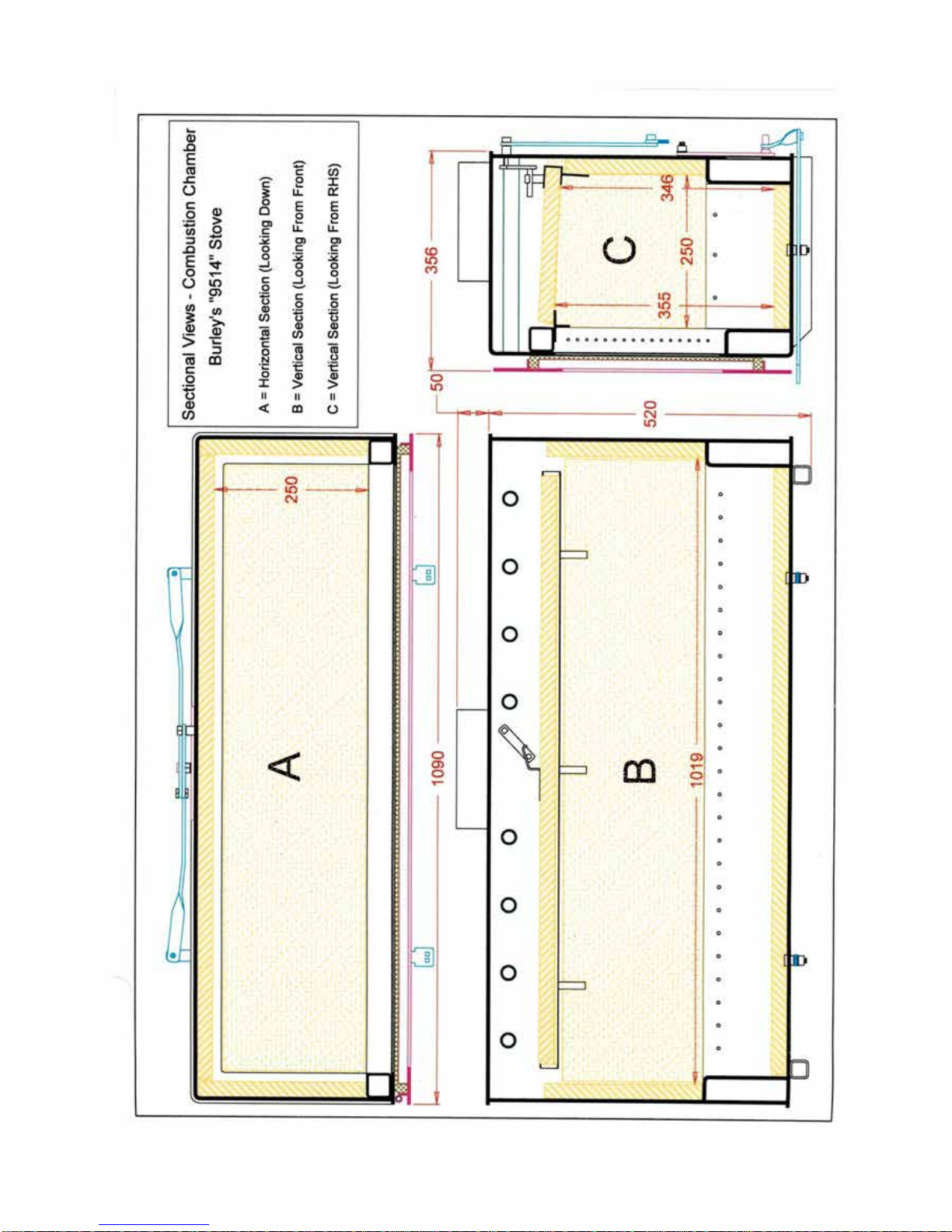

9514.................................................................................................................................................7

Approvals .......................................................................................................................................8

The Clean Air Act 1993 and Smoke Control Areas .....................................................................8

Hearths............................................................................................................................................9

Stove tables....................................................................................................................................9

Inset installations.........................................................................................................................10

Air supply .....................................................................................................................................10

Room Sealing Kit.........................................................................................................................10

Chimneys......................................................................................................................................11

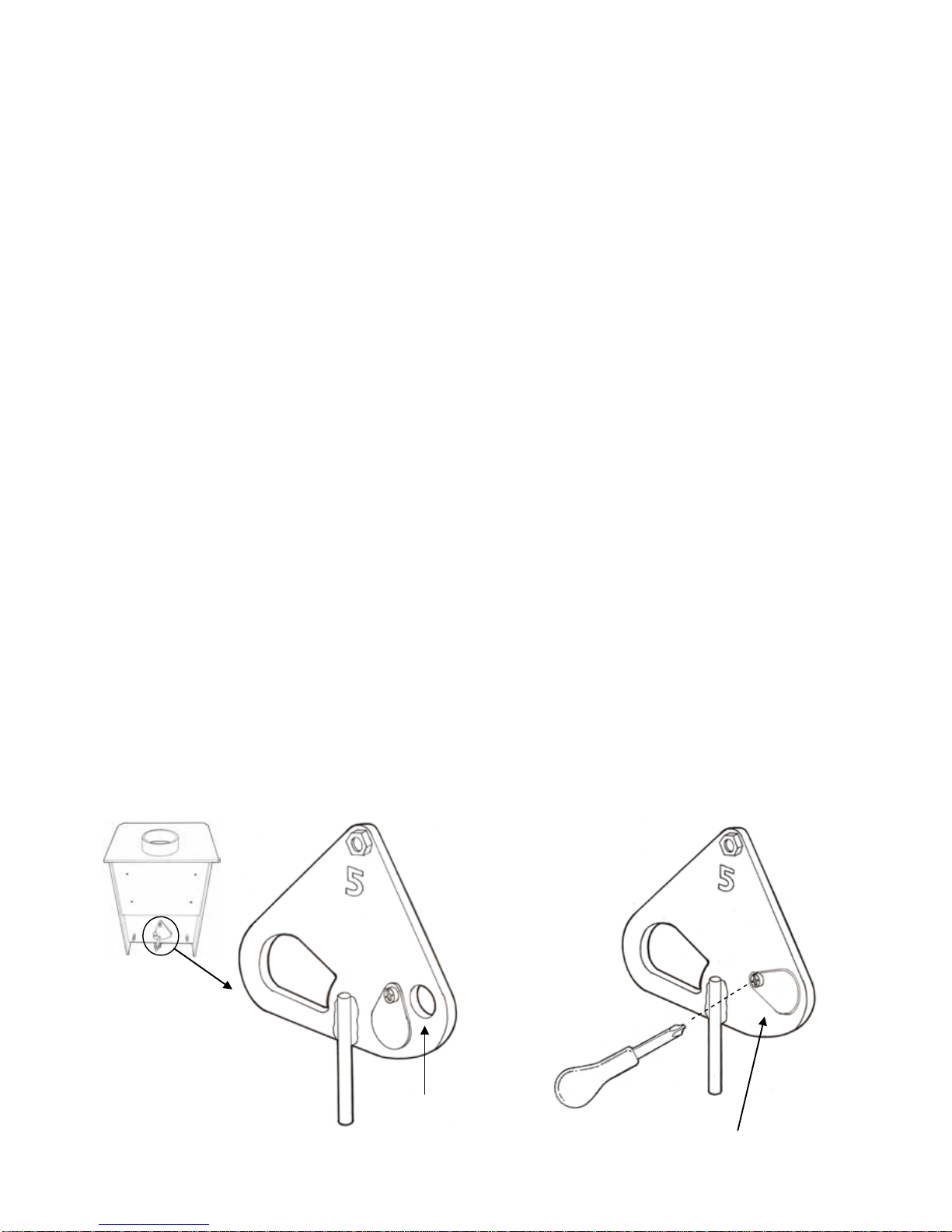

Assembly of control levers.........................................................................................................11

Installation of the stove fire bricks.............................................................................................11

Commissioning the Appliance....................................................................................................12

USER INSTRUCTIONS.................................................................................................................13

To Light the Stove........................................................................................................................13

Recommended fuels & using the Moisture Meter.....................................................................14

Stove Thermometers - DO NOT USE WITH OUR STOVES ...............................................15

Troubleshooting/Poor Appliance Operation..............................................................................16

Reasons for Premature Wear of Internal Parts..........................................................................16

Care of Glass................................................................................................................................17

Chimney Sweeping and Maintenance........................................................................................17

Safety............................................................................................................................................18

Warranty .......................................................................................................................................19

If you need further help…............................................................................................................19

Spare Parts...................................................................................................................................19

Customer & Installation Notes....................................................................................................20

PLEASE CAREFULLY CHECK YOUR STOVE FOR DAMAGE

OR DEFECTS PRIOR TO FITTING.

WE CAN NOT EXCHANGE DAMAGED OR FAULTY

STOVES THAT HAVE BEEN FITTED.