WARRANTY

The BURNDY® MRC840AL is warranted to be free of defects in materials

and workmanship for a period of 1 year, except in the case of abuse or

modication.

Any BURNDY®MRC840AL found to be defective in material or

workmanship and returned to the BURNDY®Tool Service Center within

1 year of shipment will be repaired or the tool will be replaced free of

charge at the option of the BURNDY® Tool Service Center.

After 1 year, units will be repaired and billing will be based on a sliding

scale according to how long the unit has been in service.

Any BURNDY®MRC840AL returned for repair must be shipped prepaid

to the BURNDY®Tool Service Center, 150 BURNDY Road, Littleton,

New Hampshire, USA 03561. On your packaging slip indicate the nature

of the repair required (or describe the problem) and the number of the

purchase order requesting service. Please provide a contact name and phone number in the event we

need to call you regarding the repair or service.

BURNDY®disclaims all other warranties, expressed or implied, including without limitations the warranties

of merchantability and tness for a particular purpose.

BURNDY®will not under any circumstances be liable for the cost of removal or reinstallation of goods or

the cost of disassembly or reassembly of equipment in connection therewith, or for the loss of the use

of the Buyer’s equipment or facilities, or for the loss of business or good will or prots, or for the cost

of inspection or storage, or for any incidental or consequential damages of any nature or description

whatever which may arise from BURNDY® sale of goods to Buyer.

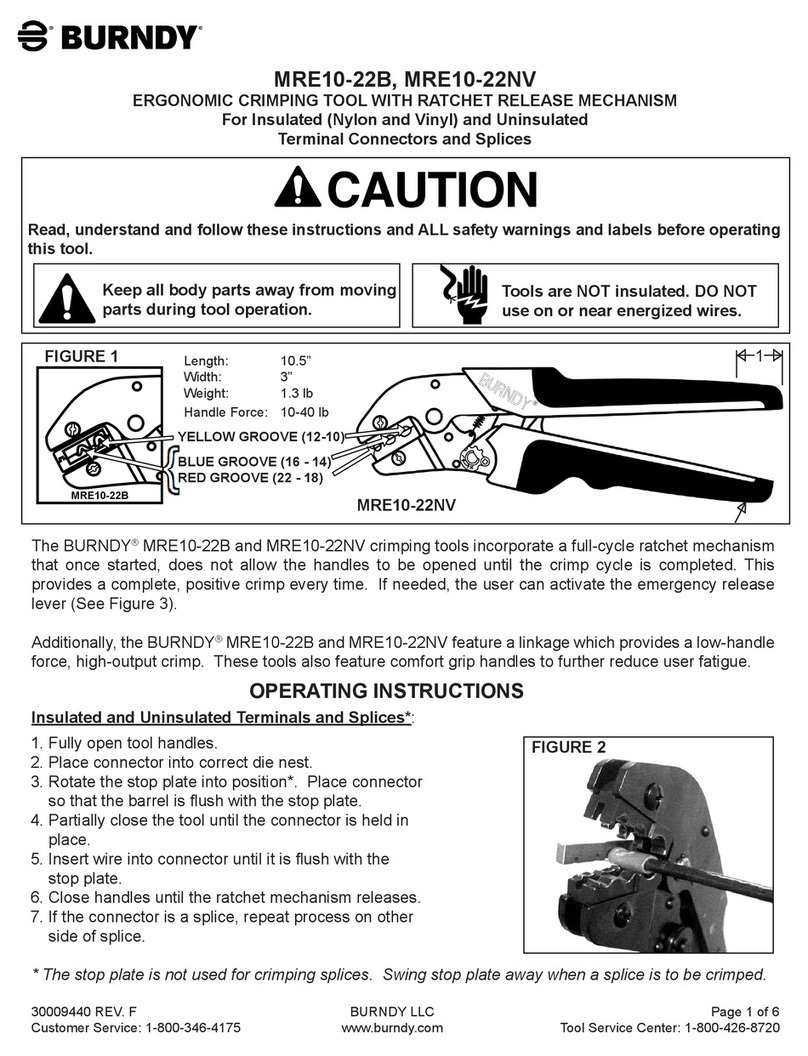

MECHANICAL ROTATABLE CRIMP TOOL

BURNDY®MRC840AL

Tools are NOT insulated for use on or near energized conductors. Use of these tools near

energized conductors may lead to electrical shock, causing severe injury or death. Do

NOT use these tools near energized conductors without adequately insulating operator

and surroundings.

OPERATING SAFETY PRECAUTIONS

FORMMRCALOMI

Rev. C

Item # 10103462

Pinch point. Keep all body parts away from the head of the tool during use to avoid serious

personal injury.

Use all appropriate personal safety equipment when handling, operating, and servicing this tool such as,

safety shoes, eye protection, and work gloves.

To help ensure safe operation of this tool, keep all safety labels clean and legible. Replace labels when

necessary with new labels.

DESCRIPTION

The BURNDY® MRC840AL mechanical crimp tool is designed to install YA-A and YS-A series connectors.

Connector/Conductor ranges are from #8 AWG through 4/0 AWG stranded copper and aluminum.

The MRC840AL is equipped with rotatable crimp die wheels that are color coded. The rotatable die

wheel crimp grooves are engraved with a die index number. The engraved index number embosses the

connector during crimping permitting permanent inspection of the completed connection.

For more information write or call:

BURNDY® TOOL SERVICE CENTER

150 BURNDY Road

Littleton, NH 03561 USA

Telephone: 1-800-426-8720

ToolRepair@burndy.com