9

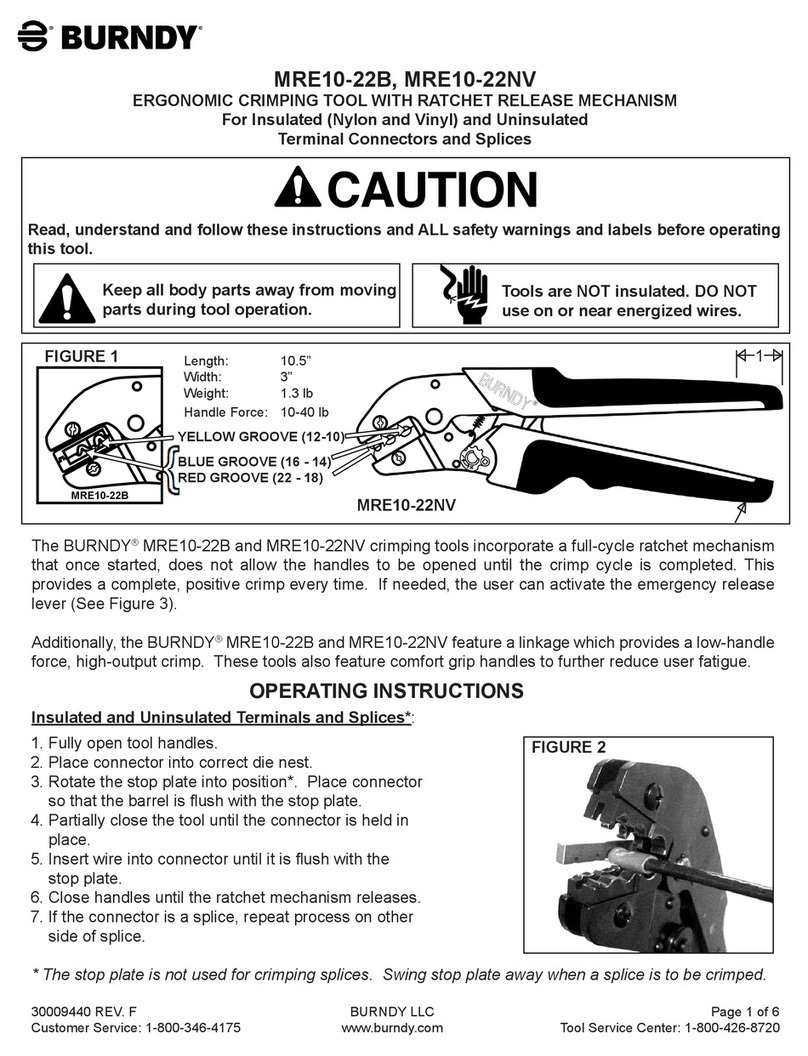

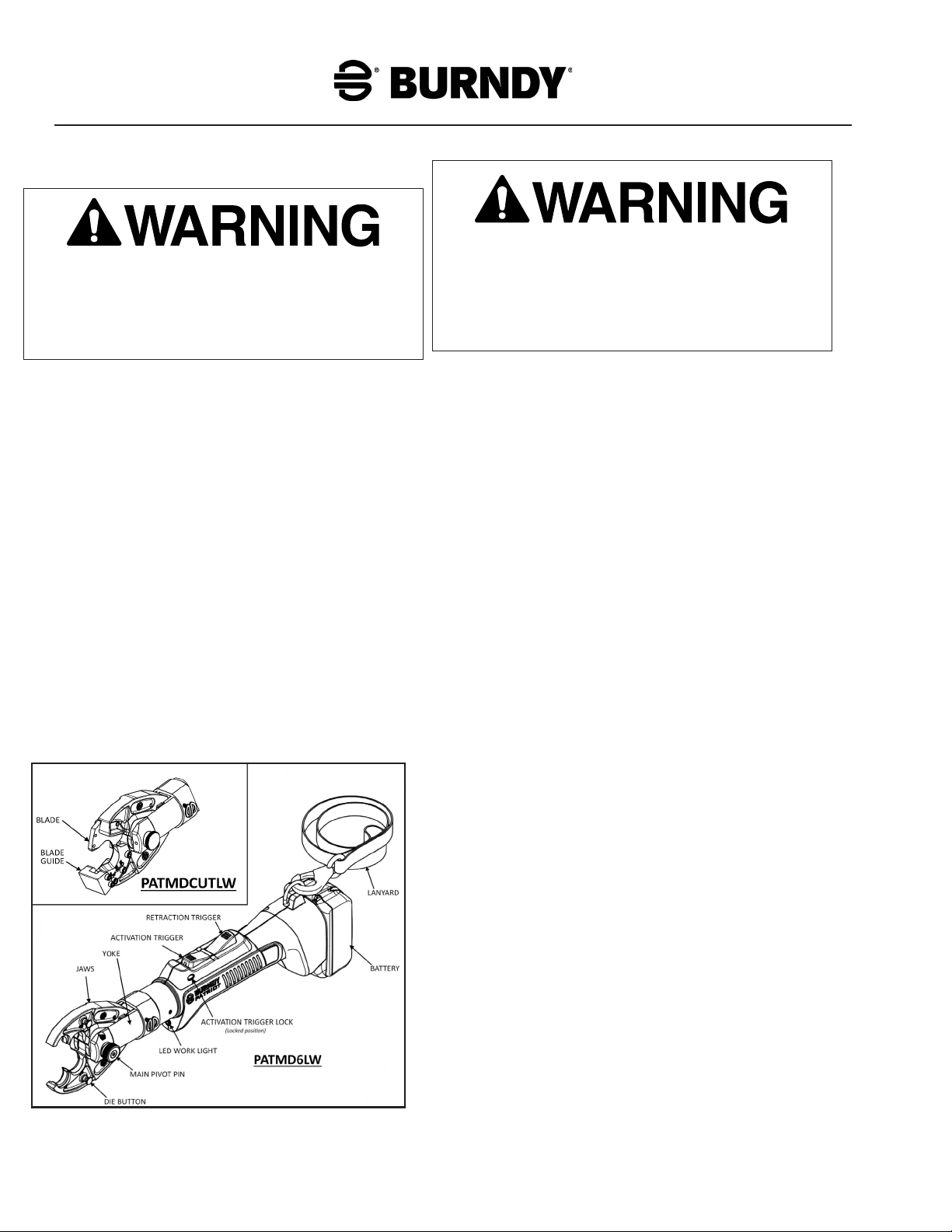

JAW INSTALLATION PROCEDURE

One of the main features of the BURNDY®PATRIOT®

IN-LINE®Crimper/Cutter tool is its ability to easily change

out and install dierent types of jaws, without the need

for any additional tools. There are several dierent types

of jaws for crimping and cutting, so it may be necessary

to switch jaws depending on the application. (See Parts

Section to order other jaw variations.)

1) Engage the activation trigger lock and then remove

battery.

2) Press the black retraction trigger to ensure the ram is

fully retracted.

3) Grip the knurled end of the main pivot pin and pull

outward. Turning the pin while pulling will make it

easier to get past the detent and pull outward. (Note:

The pin will not pull out of the yoke completely.)

4) Squeeze the jaws slightly and remove the jaws from

the tool.

5) Insert new jaws into the yoke by closing the jaws

slightly in your hand. Line up the tabs at the base of

the jaws with the notches in the yoke.

6) Push the pin inward so that it is fully inserted into the

jaws and yoke.

BLADE REPLACEMENT PROCEDURE

If the blades wear out, it will be necessary to change out

and install new blades. (See Parts Section to order new

blades and guide.)

Required Tools: 9/64" Allen Wrench, 5/32" Allen Wrench

1) Engage the activation trigger lock and then remove

battery.

2) Remove the guide by removing the #8-32 socket head

cap screws.

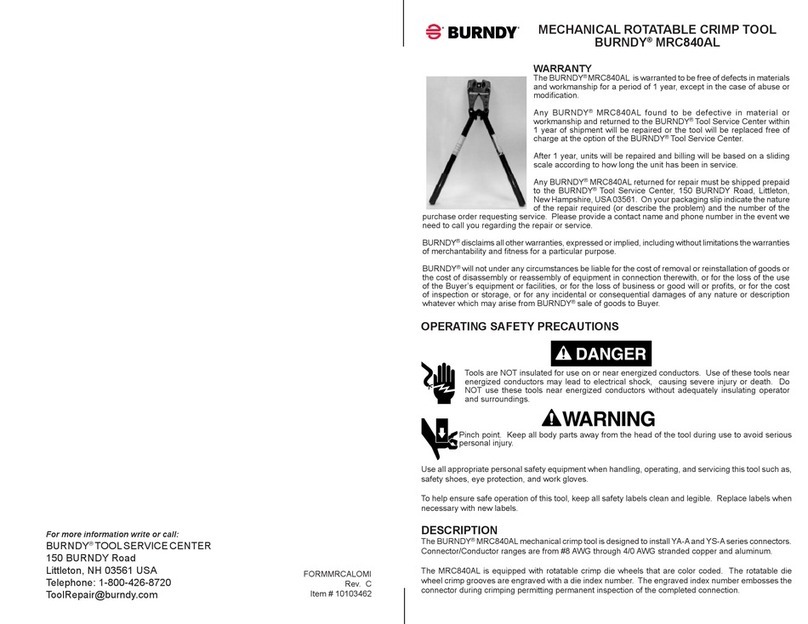

OPERATION

Read and follow all pre-operation and

safety instructions provided for your

PATRIOT®IN-LINE®Crimper/Cutter and

for the battery charger (see Charger

Instruction Manual) and accessories.

Failure to follow the proper operating

instructions and safety information

provided can lead to serious personal

injury or death.

This tool is NOT insulated for use on or

near energized conductors. Use of this

tool near energized conductors may lead

to electrical shock, causing severe injury

or death.

Pinch point hazard. Crimp ram operates

at high speed and force and can cause

severe personal injury. Keep all body

parts away from moving parts of the tool,

especially the area of the head and die

holder during operation.

Blade hazard. Cutter blades move at

high speed and force and can cause

severe personal injury. Keep all body

parts away from moving parts of the tool

during operation.

NOTE: Do not immerse the tool in water, as the PATRIOT®

IN-LINE®Crimper/Cutter is not designed to operate under

water. This is considered abuse and will void the warranty!

Always use the tool lanyard provided to prevent dropping

the PATRIOT®IN-LINE®Crimper/Cutter.

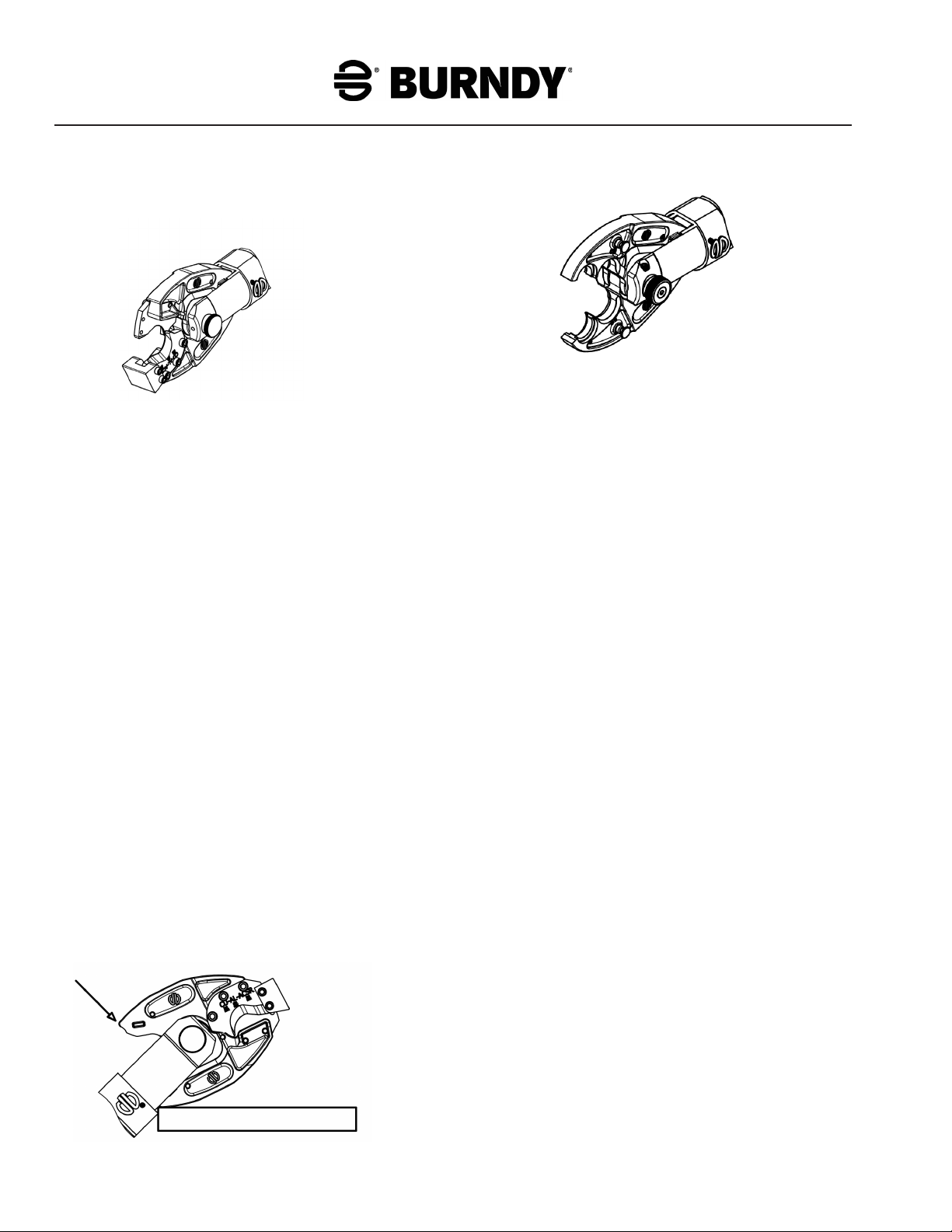

BLADE REPLACEMENT Continued

3) Remove each blade by removing the three

#10-32 x 1/2" socket head cap screws on both sides.

4) Install the new blades and secure with the three

#10-32 x 1/2" cap screws on each side.

5) Install the blade guide and secure with the #8-32

socket head cap screws.

6) Be sure that all screws are tight before operating the

tool.

7) Cycle the tool. Make sure that there is no interference

and that the jaws advance and retract smoothly.

DIE INSTALLATION PROCEDURE

For the majority of crimped connections, it is necessary to

select and install the appropriate die for the application.

Please refer to the connector catalog page or the die

index number shown on the connector to determine the

correct die set.

To Install:

1) Select the appropriate die for the application.

2) Engage the activation trigger lock and then remove

battery.

3) Push in die button while inserting the die into the crimp

jaws. The second die may have to be installed via the

top of the tool. (Note: For polarized dies – W28RT for

example – orient the dies in the crimp jaws according

to the arrow stamped on the die.)

To Remove:

1) Engage the activation trigger lock and then remove

battery.

2). Push in die button while removing the die.

Note: The rst die may have to be removed out the

top of the tool.