33

• Study, understand, and follow all

instructionsprovidedwithandonthis

devicebeforeuse.

• All WARNING statements must be

carefullyobservedtohelpprevent

personalinjury.

•

No alteration shall be made to this

device.

• Alwayswear protective gear when

operatinghydraulicequipment.

• Keephydraulicequipmentawayfrom

ames and heat. Hydraulic uid can

igniteandburn.Donotoperateifleaks

aredetected.

•

Crush Hazard. Keephands andfeet

away from loading area.Avoid pinch

points or crush points that can be

created by the load, cylinder, or any

equipmentofsystem.

•

Toavoidcrushingandrelatedinjuries:

NEVERwork on, under or around a

liftedloadbeforeitisproperlysupported

byappropriatemechanicalmeans.

Neverrelyonhydraulicpressurealone

tosupportload.

!WARNING

HYDRAULIC PUMPS

•

Theusermustbeaqualiedoperatorfamiliarwiththecorrect

operation,maintenance,anduseofpumps.Lackofknowledge

inanyoftheseareascanleadtopersonalinjury.

• Donotexceedratedcapacityofthepumporanyequipmentin

thesystem.

• Neverattempttoliftaloadweighingmorethanthecapacityof

thecylinder.

• Donotsubjectthepumpanditscomponentstoshockloads.

• Bursthazard existsifhose orconnectionpressure exceeds

ratedpressure.

•

Inspectpump,cylinder,hosesandconnectionsbeforeeachuse

topreventunsafeconditionsfromdeveloping.Donotuseifthey

aredamaged,alteredorinpoorcondition.Donotoperatethe

systemwithbentordamagedcouplerordamagedthreads.

• Neverholdor stand directlyin linewith anyhydraulic

connectionswhilepressurizing.

•

Usegaugeorotherloadmeasuringinstrumenttoverifyload.

• Never attempt to disconnect hydraulic connections under

pressure.Releasealllinepressurebeforedisconnectinghoses.

•

Useonlyapprovedaccessoriesandapprovedhydraulicuid.

•

NeverattachANYcomponentnotauthorizedbymanufacturer.

• Alwaysensurethatthechosenapplicationisstabletoworkon

andaround.

• Donotconnecttoapplicationwhichcanreturnmoreoiltothe

reservoirthanthepumpreservoircanhold.

• Donotconnectpumptohydraulicsystempoweredbyanother

pump.

• This device is not suitable for use as support device! As

thesystemloadislifted,useblockingandcribbingtoguard

againstafallingload.

• All personnel must be clear before lowering load or

depressurizingthesystem.

• Nevertrytodisassembleahydrauliccylinder,referrepairsto

qualied,authorizedpersonnel.

HYDRAULIC HOSES & FLUID TRANSMISSION LINES

• Avoidshortrunsofstraightlinetubing.Straightlinerunsdo

notprovideforexpansionandcontractionduetopressure

and/ortemperaturechanges.

• Reduce stress in tube lines. Long tubing runs should be

supportedbybracketsorclips.Beforeoperatingthepump,

tighten all hose connections with proper tools. Do not

overtighten. Connections should only be tightened securely

and leak-free. Overtightening can cause premature thread

failureorhighpressurettingstoburst.

• Should a hydraulic hose ever rupture, burst or need to be

disconnected,immediatelyshutoffthepumpandreleaseall

pressure.Neverattempttograspaleakingpressurizedhose

with your hands. The force of escaping hydraulic uid can

inictinjury.

• Donotsubjectthehosetopotentialhazardsuchasre,sharp

objects,extremeheatorcold,orheavyimpact.

• Donotallowthehosetokink,twist,curl,crush,cutorbendso

tightlythattheuidowwithinthehoseisblockedorreduced.

Periodicallyinspectthehoseforwear.

• Donotpull,positionormovesetupbythehose.

•

Hose material and coupler seals must be compatible with

hydraulicuidused.Hosesalsomustnotcomeincontactwith

corrosivematerialssuchasbatteryacid,creosote-impregnated

objectsandwetpaint.Neverpaintacouplerorhose.

•

FAILURE TO HEED THESE WARNINGS MAY RESULT IN

PERSONALINJURYASWELLASPROPERTYDAMAGE.

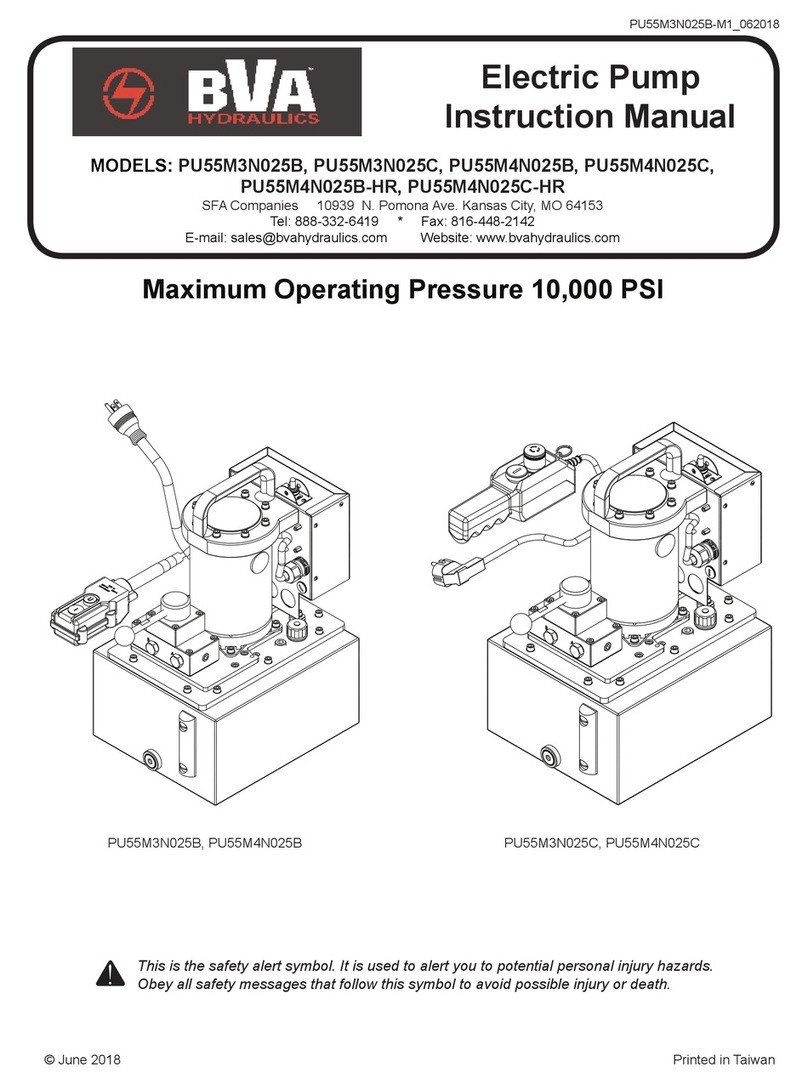

SPECIFICATIONS

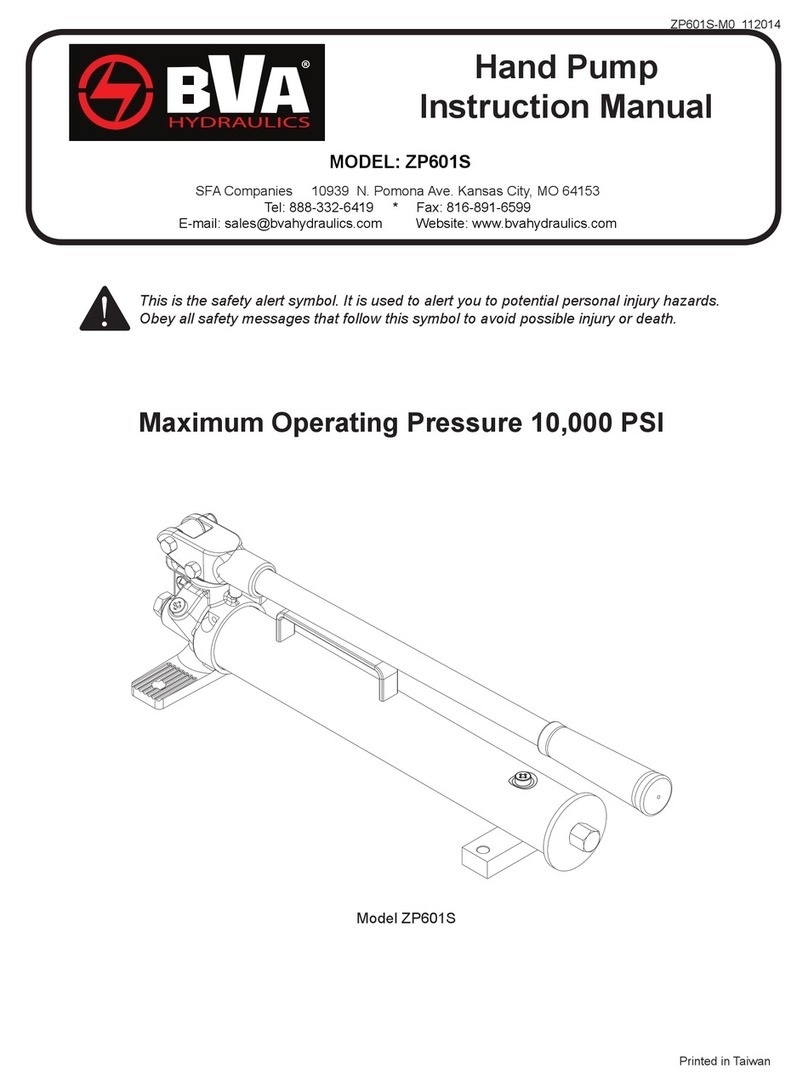

Model

Usable Oil

Capacity

(in3)

Used with

Cylinder

Pressure

Rating (psi)

Oil Displacement

per Stoke

(in3)Max Operating

Force

(lbs.)

Pump Size

(L x W x H)

Weight

(lbs)

1st

stage

2nd

stage

1st

stage

2nd

stage

P8701

476

Single

Acting 290 10,000 7.31 0.29 143 30.35”x15.24”x11.61”

76

P8701M Double

Acting 77.4