7

www.cagsanmerdiven.com

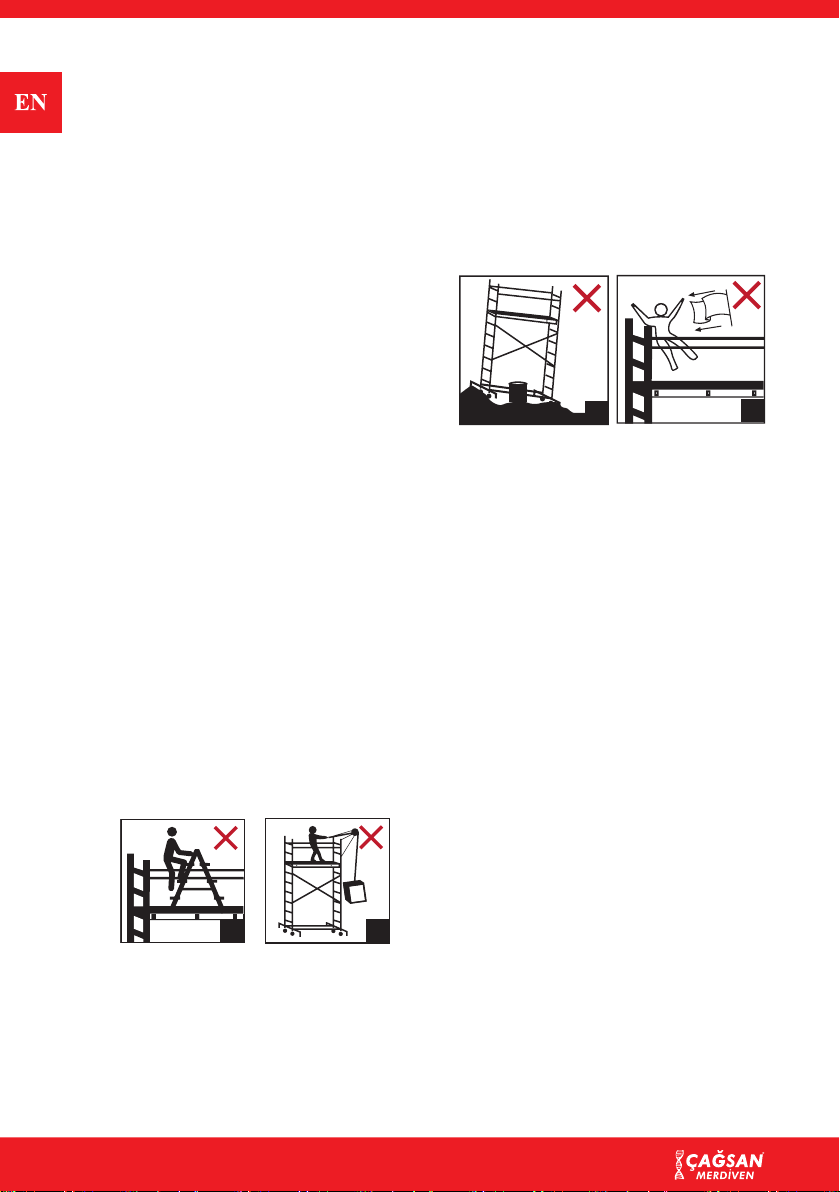

• Environmental factors such as the

previously opened doors, windload,

shades, automatically used sunsha-

des, electricity cables above, trafc

and/or the people crossing the road

etc. should be examined while mo-

ving TeleSafe Scaffold in order to

prevent danger.

• The place of the TeleSafe Scaffold

should only be changed lengthways

or towards cross direction on a surfa-

ce that carries enough at, horizontal

and enough load manually.

• Ensure that TeleSafe Scaffolds does

not tilt while moving.

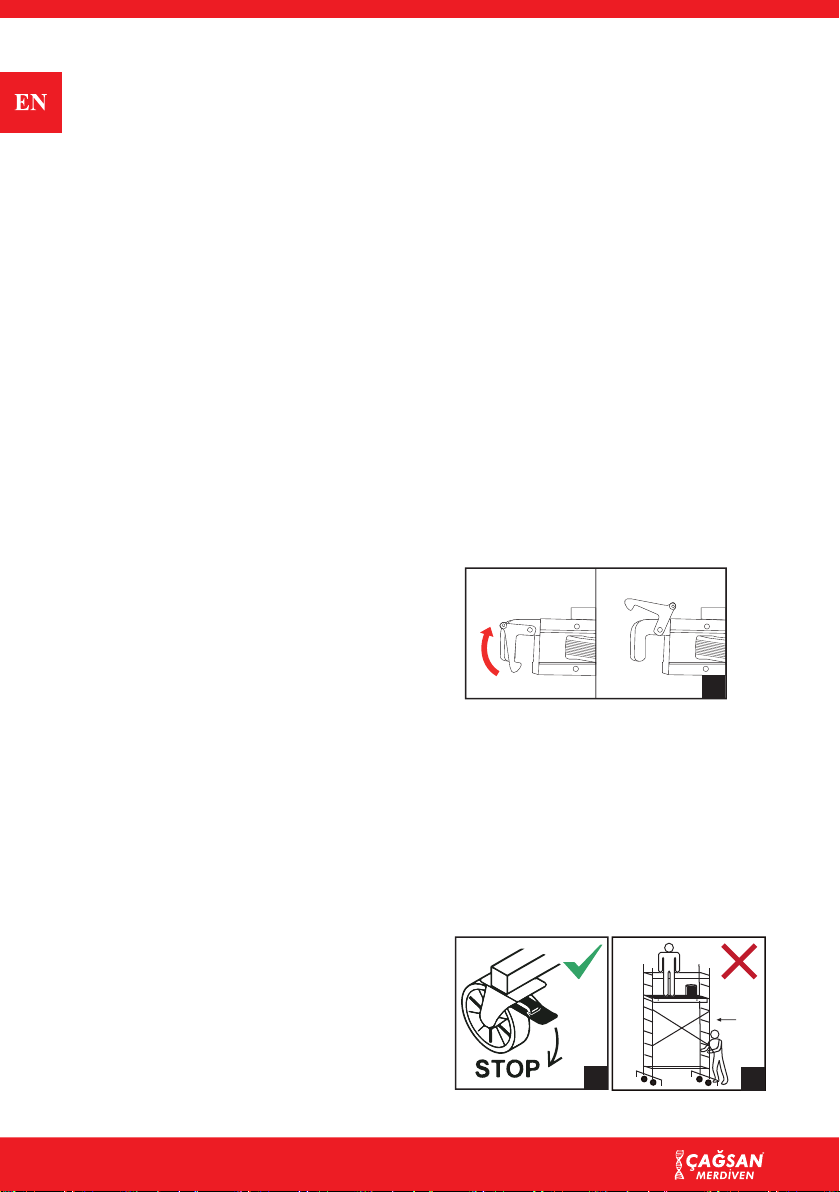

• Right after relocation of TeleSafe

Scaffold, brake pedals should be pus-

hed and wheeled legs should be enga-

ged and locked.

• After relocation, scaffold needs to be

horizontally aligned again, this should

be done by using a level.

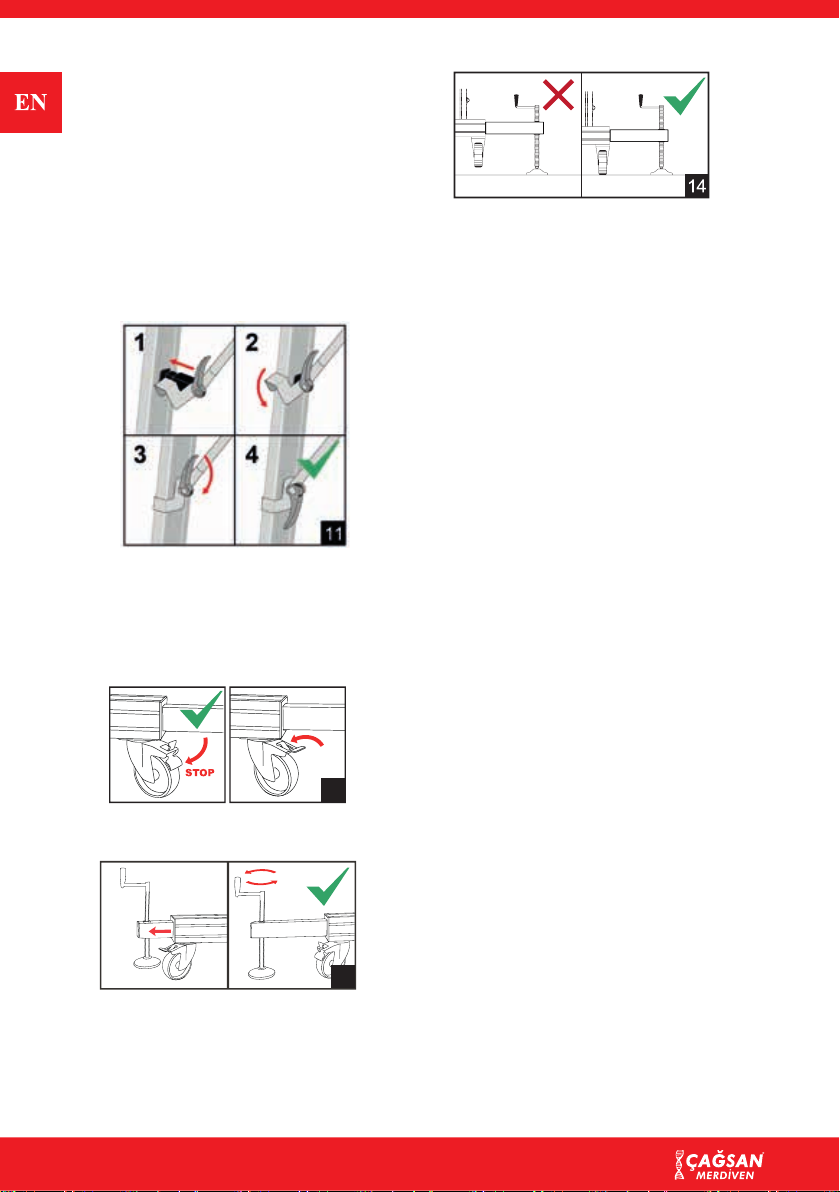

• Adjust all stabizers in a way that

they will all contact with the surface.

2.8 Assembly and/or Repair of

Spare Parts

Take into account the national regulations

for inspections, maintanence and repair of

the working towers.

The spare parts provided by Çağsan Mer-

diven should be assembled on the right

product and in the same way as the rep-

laced part.

If assembly (connection) and/or repairs

are performed by the customer, risk and

expenses shall belong to the customer.

Çağsan Merdiven shall not be responsib-

le for damages resulting from wrong as-

sembly and/or repair.

Çağsan Merdiven may provide services

for the repair of your product and/or as-

sembly of the said part with payment

2.9 Guarantee Conditions

Related Çağsan Merdiven product is de-

signed, manufactured carefully and its

necessary quality controls are performed.

If this product is used in compliance with

this instruction and its usage purpose it

shall be under the guarantee with the fol-

lowing conditions:

4. Çağsan Merdiven guarantees the reli-

ability of the product and the quality

of the materials used for the product.

5. If there is a fault in production, the

faulty part or the product is replaced

under the guarantee scope and the

problem is solved.

6. The faults that are not covered with

the guarantee are those stated below:

a) Usage of product in violation of

usage purpose and usage instructions.

b) Normalwearandtear oftheproduct.

c)Assembly or repair performed by

the customer or third parties (the rep-

lacement of spare parts provided by

Çağsan Merdiven as shown in the 2nd

article above is excluded).

7. The faults determined during product

delivery should be immediately in-

formed to Çağsan Merdiven. If these

faults are not immediately informed

the guarantee shall be void. In order

to make a request under the guarantee

scope, Çağsan Merdiven or Çağsan

Merdiven dealer should be informed

about the product delivery and an in-

voice should be submitted.

8. Product faults should be declared to

Çağsan Merdiven or Çağsan Mer-

diven dealer as soon as possible but

within 7 days after the determination

of the fault at the latest.

9. a) If a request is made under the gu-

arantee conditions, Çağsan Merdi-

ven product shall be examined by

Quality Department. Customer ne-

eds to deliver the product to Çağsan

Merdiven for this purpose. If during

the examination it is determined

that the product was inappropriately

used, examination expenses shall

be requested from the customer.

b) If customer requests the exami-

nation to be made by an indepen-

dent organization and if as a result

of the examination it is determined

that the product was used inapprop-

riately, examination expenses shall

be covered by the customer. Even if