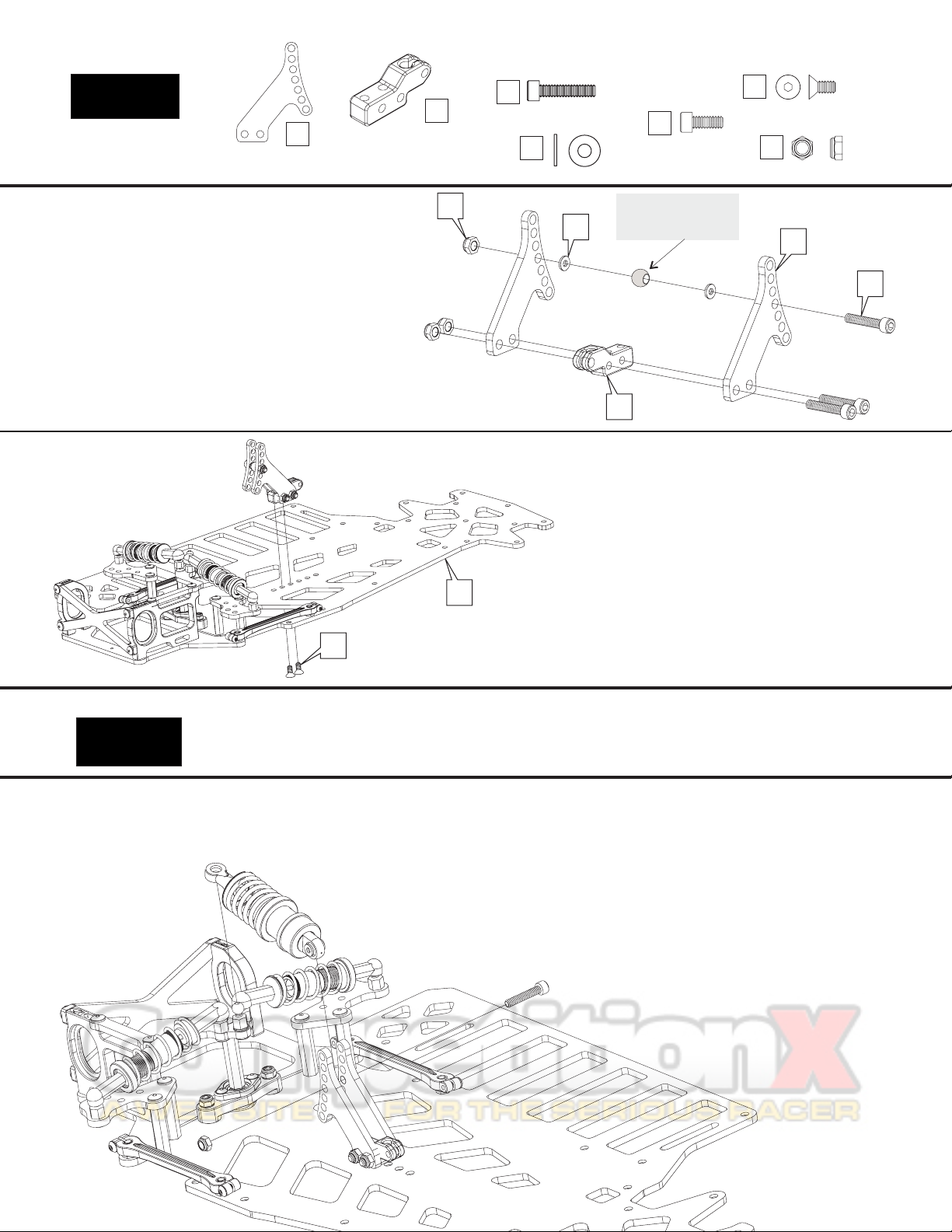

Bag 2

4-40 x 5/16”

FH steel

4-40 x ½”

FH Alum

One-Piece

Side Links

Red Low-

Profile Ball

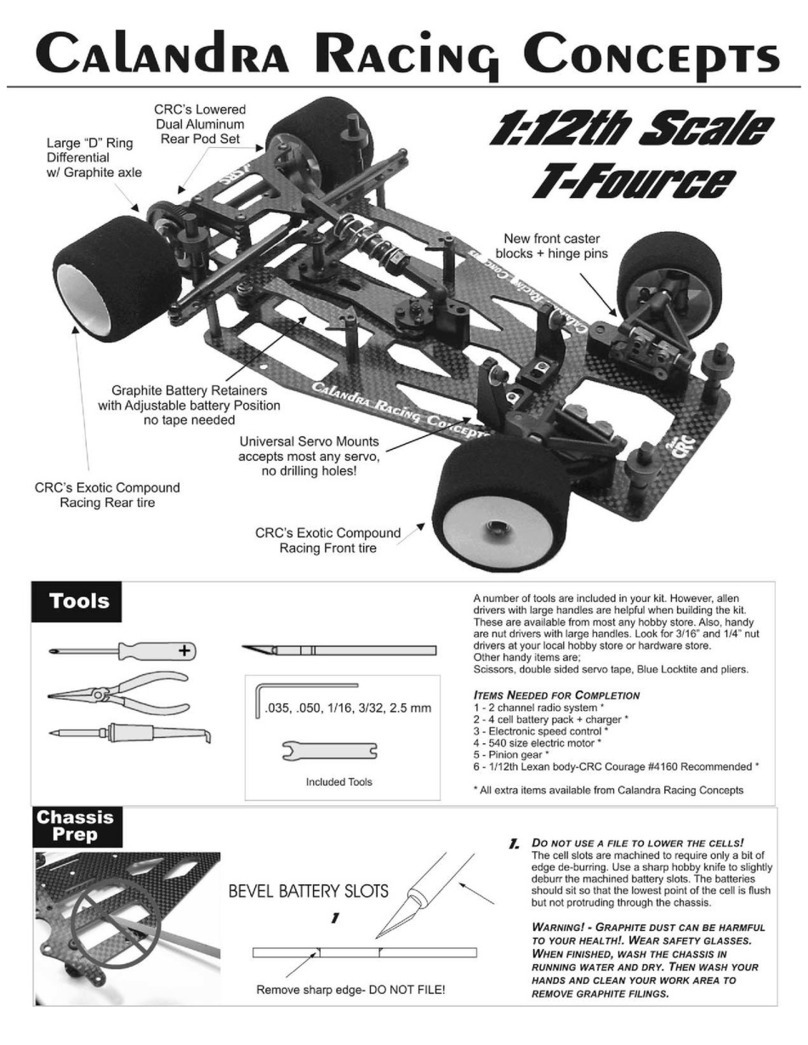

1 - In Bag 2, find the graphite bottom plate [10].

Secure it to the center pivot assembly with the

½” red flat head screw [11]. Secure it tight with

the red 7/8” hex standoff [15].

2 - Find the 4 red low profile balls [12]. Secure

them as shown with the steel 5/16” screws [13].

3 - Locate the plastic side links [14]. Inspect the

links and you will notice that the screw holes on

one side of the link are larger than the holes on

the other side. Before popping the links on the

balls [12], be sure that the larger hole faces

toward the outside of the chassis.

4 - Slide the 2-56 button head screws [4]

through the large holes in the outside of the side

links, and then thread them into the small inner

holes as shown in the illustration. Do not tighten

these screws down all the way. Put just enough

tension on them so that there is no play in the

links, but so they pivot freely on the balls. The

car will NOT handle properly if the links are too

tight on the balls.

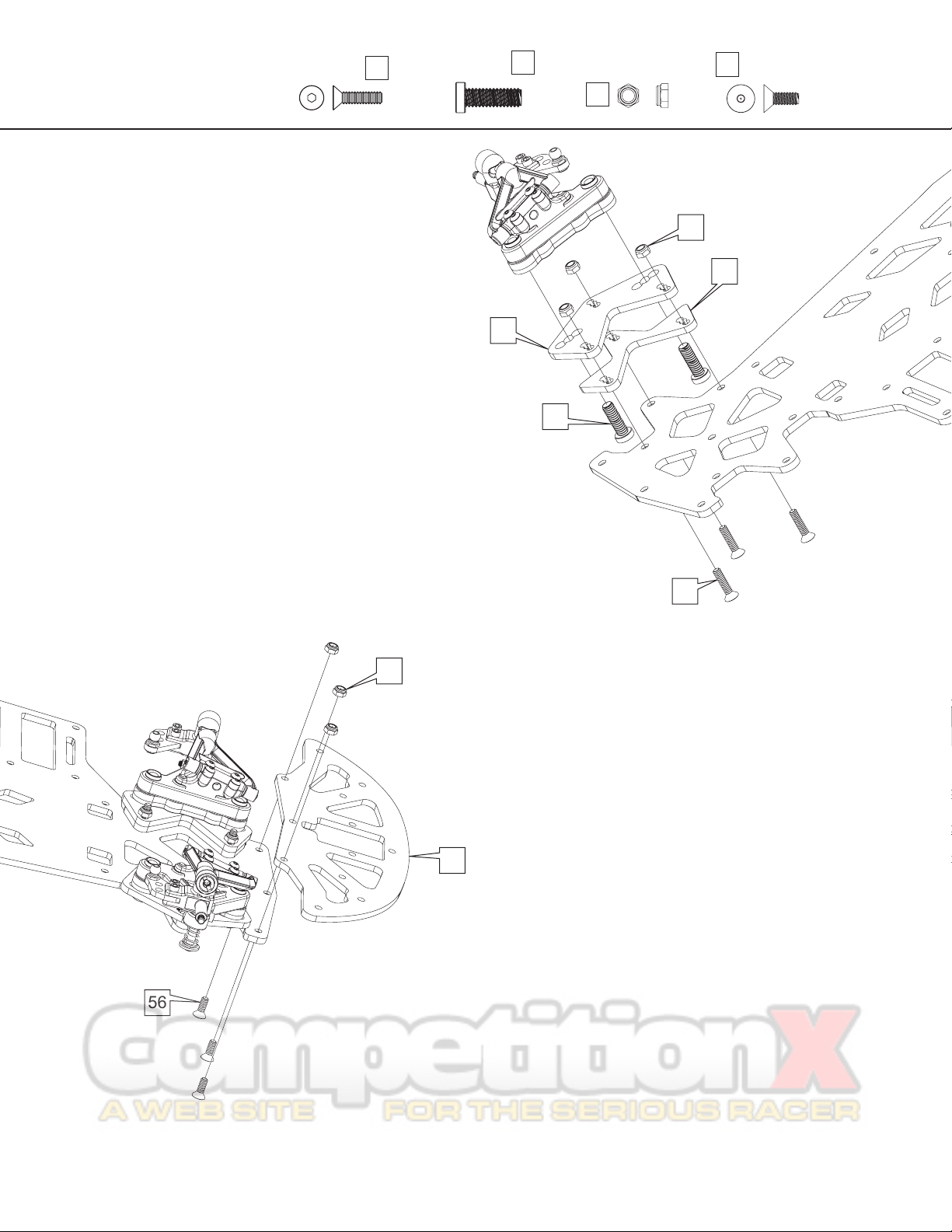

1 - Be sure the 2 aluminum locknuts on top of the center pivot are slightly loose.

There should be a washer under each alum locknut. Notice that the center pivot

“floats" or moves slightly on the 2 screws. This "floating" allows the links

to "free up". This ensures that the rear pod plate pivots freely on the links

and center pivot ball. This is a crucial step when setting up the Battle Axe.

2 - Snap the 2 links on the balls (done in previous step). They should rock freely on

the pivot balls.

3 - Place the chassis/backplate on a flat surface. No tires and

no diff on the car! A smooth table or desk should do. Be

sure that the rear bottom plate and chassis are in a

straight line, flat against the table, again, no tires on the

car. Lightly “tap” the chassis and rear pod releasing any

tension in the links. Keep the chassis flat on the table for step 4.

4 - Hold the chassis at the hold point “H” by pressing

the chassis down to the table. Slowly tighten the 2 locknuts that

secure the center pivot assembly. For now, just lightly

snug one side then the other.

5 - Pick up the car and check the pivoting action of

rear lower plate. Rotate the rear plate from side-to-

side. It should move free without binding or "clicking".

If it does not, loosen the pivot locknuts and repeat steps 3+4.

If it rotates smoothly, tighten the locknuts on the center pivot more

securely. Do this by again holding the chassis down to the table at the

hold point “H”. Slowly and carefully, fully tighten the locknuts that hold the center pivot

assembly to the chassis. The handling of the Battle Axe hinges (pun intended!) on the

free movement of this rear plate. Be sure that the rear links and rear plate are free and not binding.

(not the rear pod)

Setting the One-piece links

2

Red 7/8”

Standoff

15

15

10

11

12 14

13 11

12

13

14

Rotate

Center Pivot

H

2-56 Button Head

4

4