1

PRODUCT SPECS

WARNING

To reduce the risk of INJURY or DEATH:

•Never let children operate the gate or play around the gate. Keep the remote control away

from children.

•Always keep people and objects away from the gate. Cars, people, and other objects should

never enter when the gate is closing.

•Test gate operator monthly. The gate must reverse when it comes in contact with a solid

object, or stop when an object activates the non-contact sensors. After adjusting the force or

travel limit, re-test the gate operator. Failure to maintain the gate operator properly can

increase the risk of injury or death.

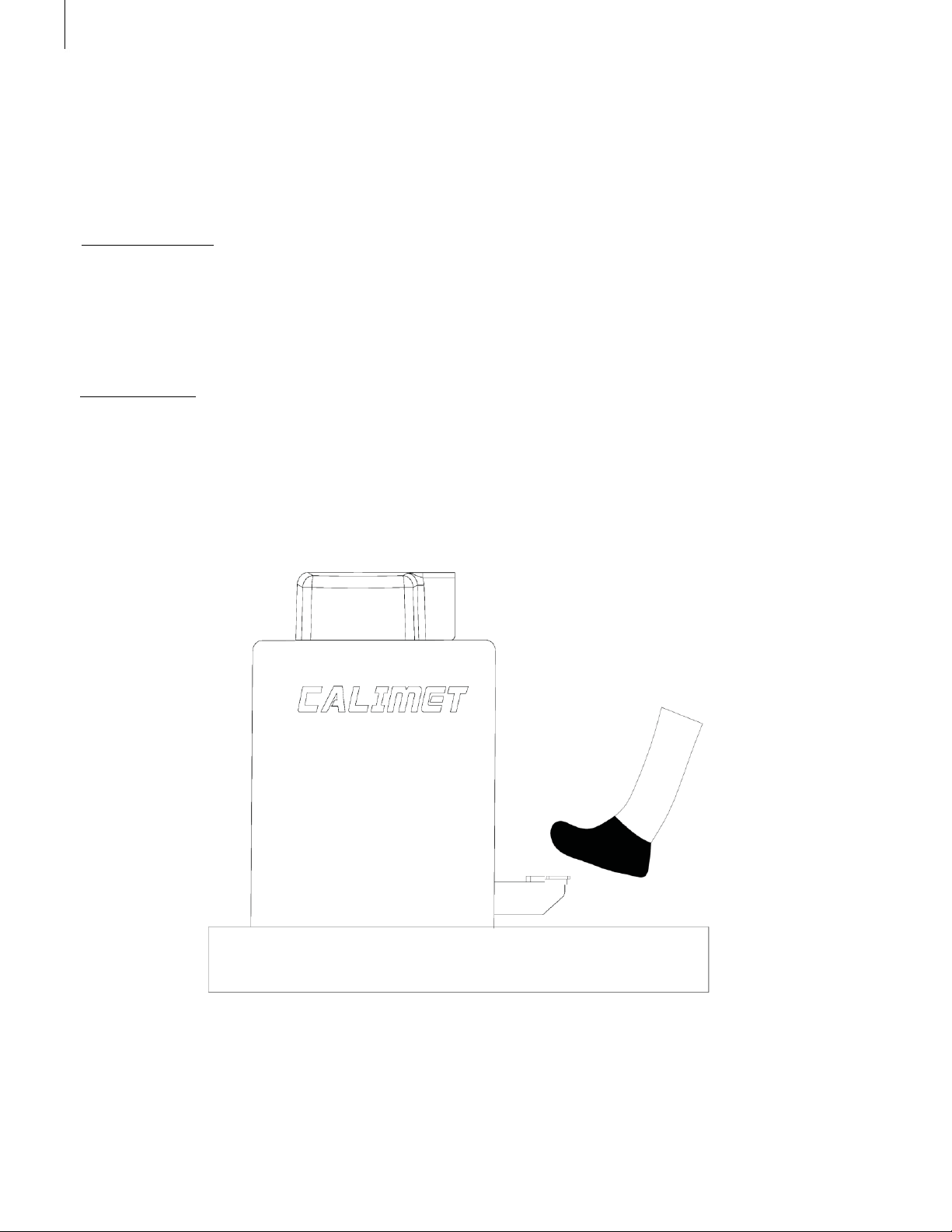

•Use the emergency release only when the gate is not moving.

•Keep the gate properly maintained. Read the owner's manual on how to maintain your gate.

Have a certified service technician make repairs or install gate operator hardware.

•The gate entrance should be used for vehicles only. Pedestrians should use a seperate entrance.

•Keep these instructions.

Voltage Input: 110V

Maximum Output Current: 15 amp, Fuse: AC 110V 15 amp

Remote Control Distance: >150 Feet (50 meters)

Maximum Gate Weight: 1000 lbs

Maximum Gate Length: 18 Feet

•Verify this operator is proper for the type and size of gate.

•Make sure the gate has been properly installed and slides freely in both directions. Repair

or replace all worn or damaged gate hardware prior to installation.

Product Specs

LANGUAGES

To download this user manual in a different language, visit calimetco.com/manuals

Para descargar este manual de usuario en otro idioma, visite calimetco.com/manuals

下载其他语言版本用户手册,请访问 calimetco.com/manuals