XI. Replacement Parts

XII. Warranty

Please visit www.cambro.com for a complete list of replacement parts. The model number

of the Cambro Vending Cart is required to determine the correct replacement part.

Cambro warrants to the original buyer that if a product proves defective:

1. Within 1 year from the date of manufacture, Cambro will replace the product free of charge; or,

2. After 1 year and up to 2 years from the date of manufacture, Cambro will grant a credit of 2/3 off replacement product; or,

3. After 2 years and up to 3 years from the date of manufacture, Cambro will grant a credit of 1/3 of the original price towards a replacement product.

TO ORDER REPLACEMENT PARTS:

• Call Cambro Customer Service at 800 833 3003 or

• Call International 714 848 1555

• Fax your order to 714 842 3430 or

• Call your local Cambro Representative or Distributor

Telephone 714 848 1555 Toll Free 800 854 7631 Customer Service 800 833 3003

© Cambro Manufacturing Company 5801 Skylab Road, Huntington Beach, California 92647-2056

Printed in USA 07/20

UMCVC75

D062006

X. Maintenance and Cleaning

The Cambro Vending Cart should be cleaned regularly.

Additionally, it should be cleaned before using if it has been idle for 5 days or more.

Vending Cart Body/Display Case/Extender/Compartments

Steam clean or wash with warm soapy water and a soft plastic or bristle brush. NEVER use a metal brush or abrasive cleaner.

Scrub with brush, and rinse thoroughly with clean water. If staining occurs, any standard de-stainer such as Ecolab’s “Dip It” should be used.

Clear Plastic Sneeze Guard Shield

Wash the clear plastic shield with warm soapy water. Rinse thoroughly. Dry with soft cloth or soft paper towel.

NEVER use alcohol, i.e. Windex, abrasives, any type of solvent or acetone

Alcohol based cleaners will cause the shield to crack.

Vinyl Umbrella, Metal Umbrella Pole and Support Pole

Refer to your umbrella manufacturer care and maintenance manual.

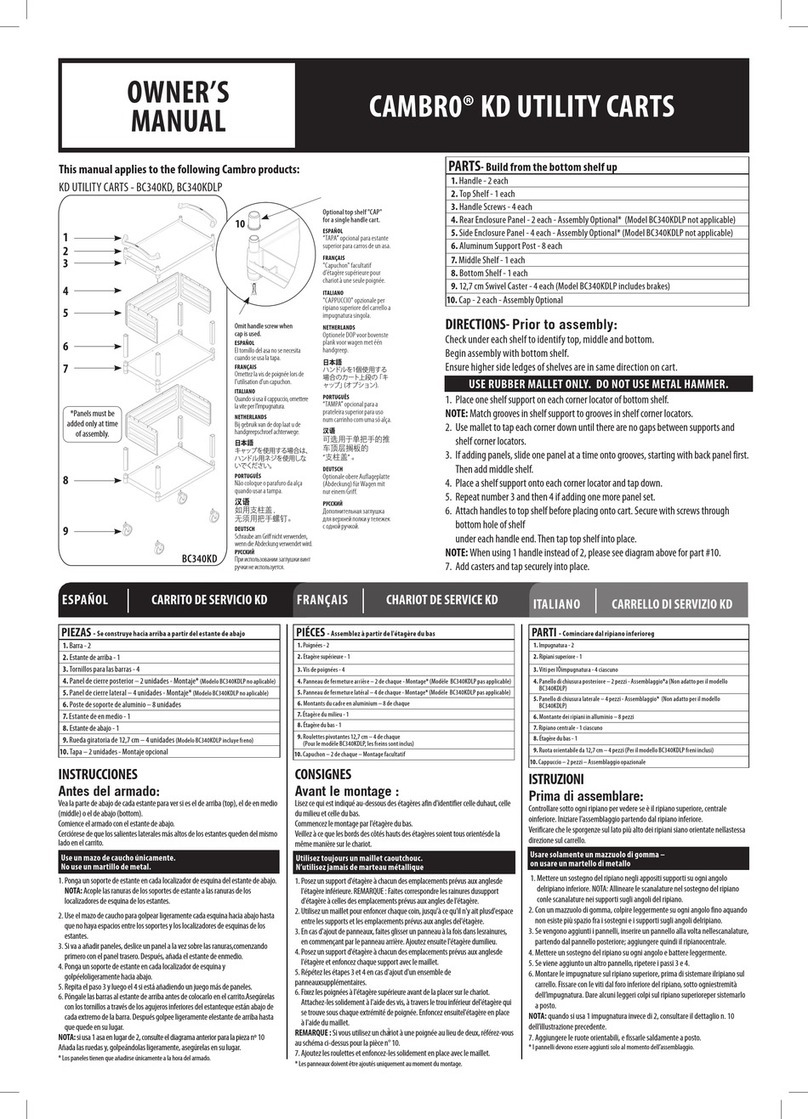

Fig. 6 Fig. 7

CASTERS

Caster maintenance should be performed after every cleaning.

1. Grease swivel raceway of caster using a lubricant such as

Lubriplate #930-AA, Keystone #84EPXLT multi-purpose

grease or equivalent. Apply grease using a grease gun with

a needle nose adapter or a tube-type applicator such as

Sta-lube Moly-graph Assembly Lube (Fig.6). These can be

obtained at most auto parts stores.

2. Use a light oil such as WD-40 on the hub (Fig.7). Check

caster for damage and test caster spin and swivel rotation

before returning to service.

COMPLEMENTARY ACCESSORIES

CODE DESCRIPTION

OVERALL DIMENSIONS

L x W x H

UPC300 Ultra pan carrier 17" x 253⁄4" x 223⁄8"

EPP300 Cam GoBox®front loader 25.2" x 17.3" x 18.7"

EPP140 Cam GoBox top loader 23.6" x 15.7" x 8.5"

EPP160 Cam GoBox top loader 23.6" x 15.7" x 10"

EPPFLID Flip lid for Cam GoBoxes 23.6" x 15.7" x 1.6"

CB1220 Cutting Board 21" x 131⁄8" x 1⁄2"

CPB1220 Buffet Camchiller®181⁄2" x 125⁄8" x 4"

DIV12 12" Divider Bar 123⁄4" L

DIV20 20" Divider Bar 207⁄8" L

VBRWC Versa Well Cover 207⁄8" x 13" x 2"

CPH3 Crock holder 127⁄8" x 207⁄8"

SBH15 Salad bowl holder for 15" bowl 253⁄4" x 207⁄8"

SBH18 Salad bowl holder for 18" bowl 253⁄4" x 207⁄8"

Case Pack: 1 DIV12 and DIV20 Case Pack: 3

OPTIONAL ACCESSORIES

CODE DESCRIPTION

CVC75LET Left end table

CVC75RET Right end table

CVC75DC6 6" tall display case

CVC75DC12 12" tall display case

CVC75DCE6 6" tall display case extender

CVC75DCE12 12" tall display case extender

CVC75LSRL Lower shelves, set of 2

Case Pack: 2 CVC75LSRL Case Pack: 1

Scan to video on

adjusting CVC

Caster to xed or

swivel position.