Camfil EMC EMC_SPEC018_C2.doc Rev. D –2020 05 19

2Content

1 Updates................................................................................................................................2

2 Content ................................................................................................................................3

3 Purpose & Scope..................................................................................................................5

4 Product Presentation...........................................................................................................6

4.1 Design Features ...................................................................................................................6

4.1.1 CamSafe Certification Levels................................................................................................6

4.1.2 Airflow Options....................................................................................................................6

4.2 Materials & Temperature Limitations .................................................................................7

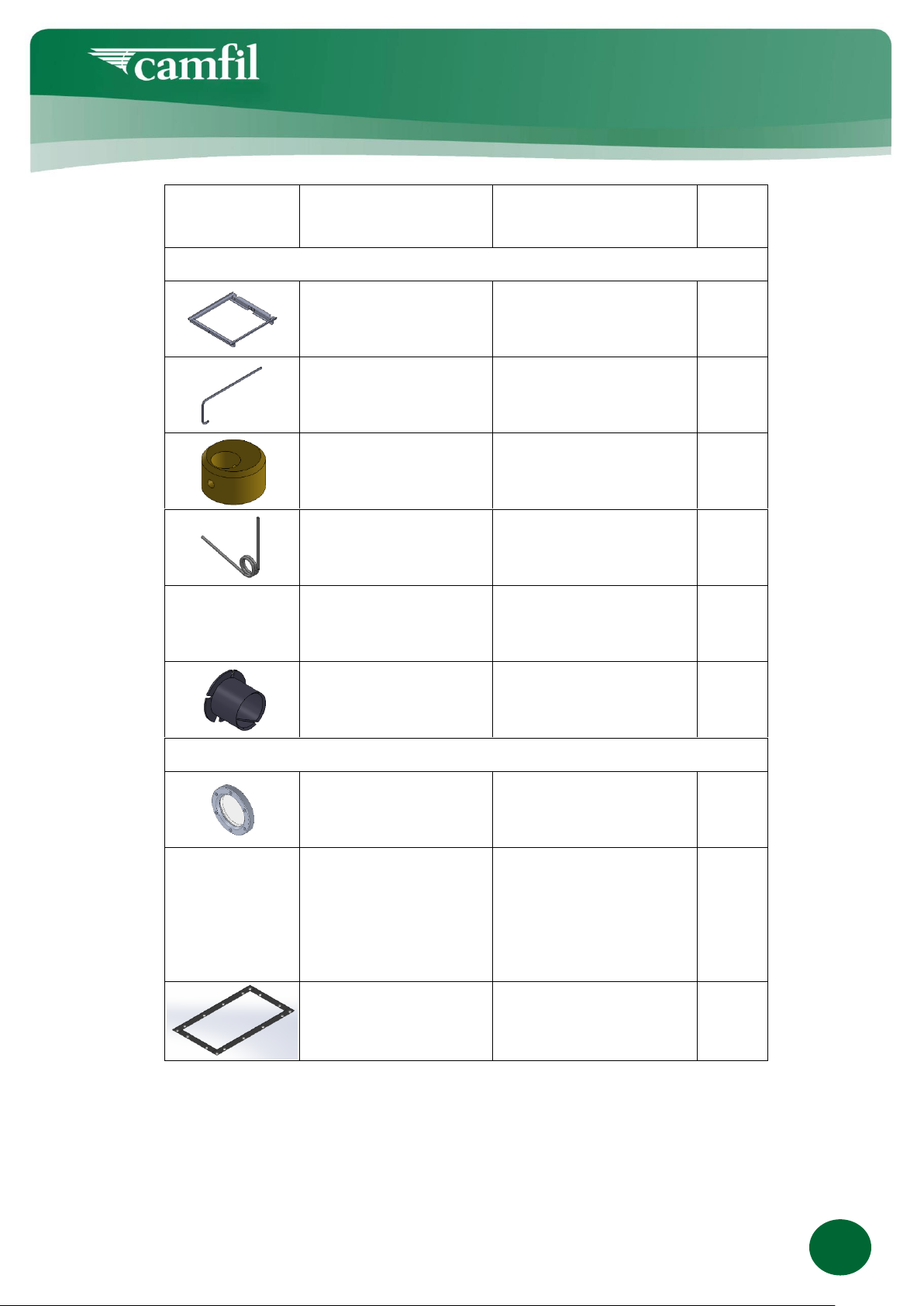

4.2.1 Materials..............................................................................................................................7

4.2.2 Temperature Limitations .....................................................................................................8

4.3 Corrosion Resistance ........................................................................................................ 10

5 Quality Control.................................................................................................................. 11

6 Goods Reception............................................................................................................... 11

7 Prior to Mounting or Intervention.................................................................................... 12

8 Mounting of Configurations.............................................................................................. 13

8.1 General Assembly of Housings / Collectors...................................................................... 13

8.2 Assembly of Horizontal Airflow Configurations................................................................ 15

8.3 Assembly of Wall Mounted Configurations...................................................................... 16

8.4 Installation of Free Standing Configurations .................................................................... 17

8.5 Installation of Wall-mounted Configurations ................................................................... 18

8.5.1 Wall Cutout Dimensions ................................................................................................... 19

8.5.2 Wall Flange........................................................................................................................ 19

8.5.3 Air Inlet Installation .......................................................................................................... 20

8.5.4 Door Module Installation.................................................................................................. 21

8.6 Installation of Add-ons...................................................................................................... 22

8.6.1 Support Stands.................................................................................................................. 22

8.6.2 Manometer Supports........................................................................................................ 23

8.6.3 Manometer Hookup ......................................................................................................... 24