PSR/AM/0912 Page 7

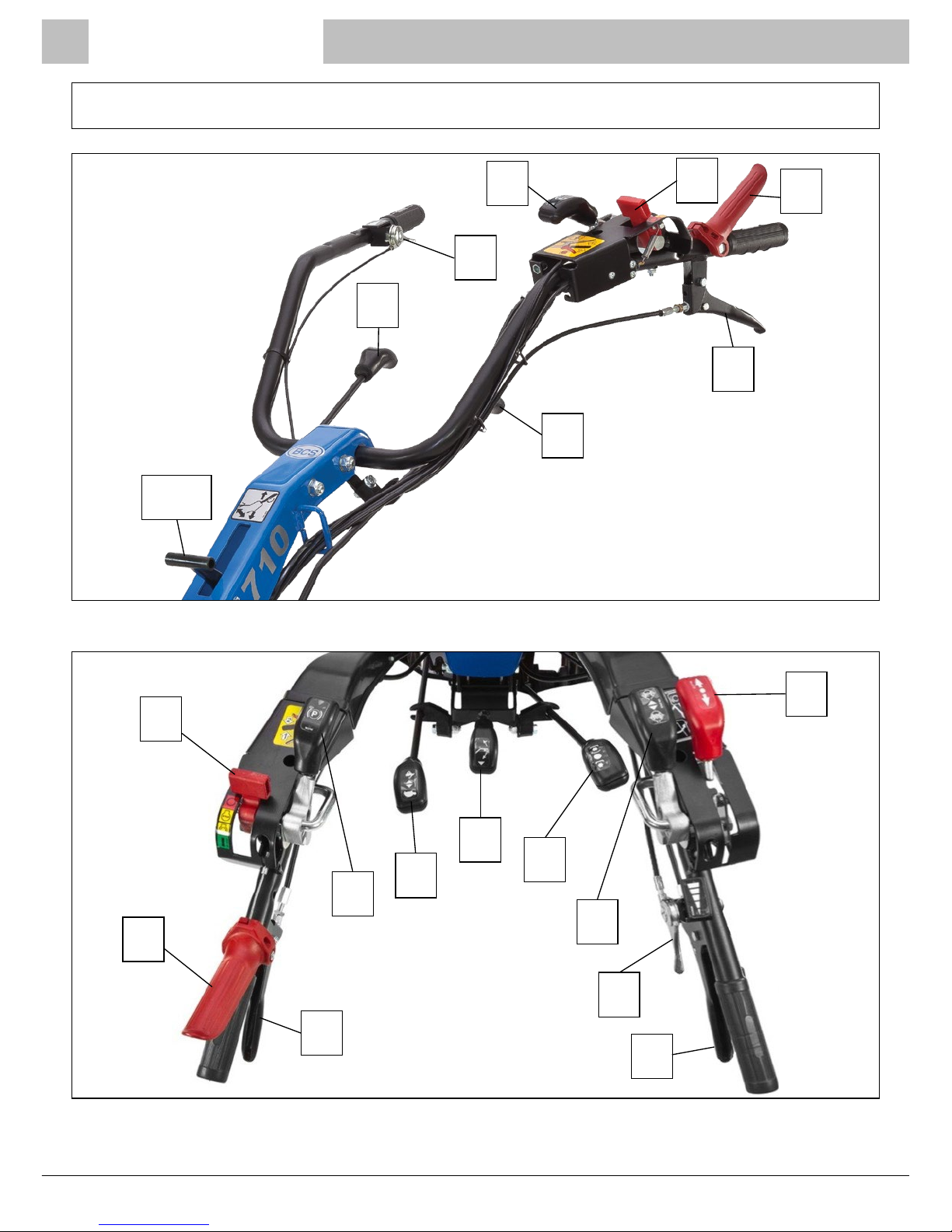

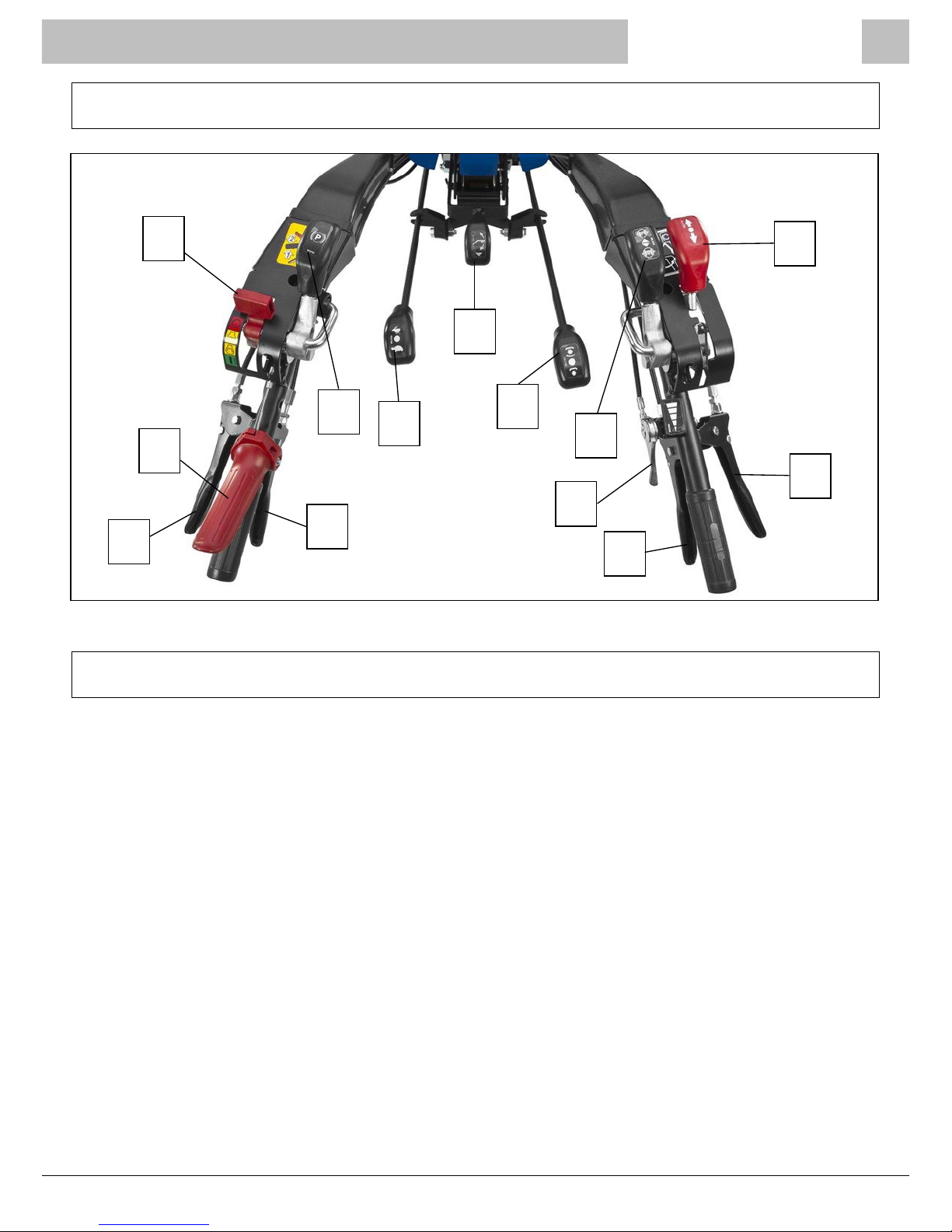

To Start Petrol Engine

Using the dipstick provided, check the engine oil level. Top up with 10w/40 oil if necessary.

Checkfuellevel.Onlyuseunleadedpetrolfromacleancontainer.Neverre-fuelwhentheengineis

hot or running. Leave 1” air space in the fuel tank.

Turn the fuel tap to ‘ON’ position, if the engine is cold set the choke lever to ‘ON’ position.

Beforestartingtheengineensurethegearlever(D)isinneutralpositionandthepowertake-off

(PTO) lever is disengaged (E).

Apply half throttle (F).

Move the engine stop lever (B) to position 1 ‘ON’.

Pull the recoil start handle gently until it engages then give it a good strong pull to start the engine.

When the engine has started, release the choke lever after a few seconds and return the throttle

lever (F) to idle position.

Lombardini Diesel Engines

Using the dipstick provided, check the engine oil

level. Top up with 10w/40 oil if necessary.

Check fuel level. Only use diesel from a clean

container.Neverre-fuelwhentheengineishot

or running.

Before starting the engine ensure the gear lever

(D)isinneutralpositionandthepowertake-off

(PTO) lever is disengaged (E).

Apply ¾ throttle (F).

Move the engine stop lever (B) to position 1 ‘ON’.

Pull the recoil start handle gently until it

engages then give it a good strong pull to start

the engine.

Once the engine has started return the throttle

lever (F) to idle position.

Yanmar Diesel Engines

Using the dipstick provided, check the engine oil

level. Top up with 10w/40 oil if necessary.

Check fuel level. Only use diesel from a clean

container.Neverre-fuelwhentheengineishot

or running.

Before starting the engine ensure the gear lever

(D)isinneutralpositionandthepowertake-off

(PTO) lever is disengaged (E).

Apply ¾ throttle (F).

Move the engine stop lever (B) to position 1 ‘ON’.

Press and hold the decompression lever on top

of the engine.

Pull recoil start handle gently until it engages

then, keeping the decompression lever

depressed,slowlypulltheengineover2-3times

to prime the engine.

Release the decompression lever and gently pull

over the engine until compression is felt.

Press, but do not hold, the decompression lever

and give the starter handle a good strong pull to

start the engine.

Once the engine has started return the throttle

lever (F) to idle position.

To Start Diesel Engines