WORKING

THE

MACHINE

Start the engine according to the engine instruction

book. Lift the clutch lever and engage the required gear.

DO NOT FORCE THE GEARS INTO MESH. If they do

not immediately engage, release the clutch lever

momentarily.

The slight noise which may be heard when the clutch

is engaged is due to the positive action of the twin

clutch plates.

When in a position to begin Rotavating, lift the clutch

lever again, and move the rotor engagement lever to

the "IN" position.Increase the engine speed and gently

release the clutch, allowing the machine to pull itself

into the work.

The rotor engagement lever also operates the differ-

ential lock. The lever must therefore be put into the

"OUT" position for turning.

The depth is controlled by pressing the depth control

lever to the right. This releases the skid in the socket,

allowing itto be repositioned as required.The skid itself

has two alternative holes, the lower one of which per-

mits a greater depth to be obtained.

Choose the depth to suit the crop being planted. Itthis

is deeper than can be obtained in one pass without the

engine labouring, several passes should be made at

progressively increasing depths.

First gear should be used for heavy work, and where a

fine tilth is required Second gear should be used for

average conditions, and top gear for light hoeing and

road work.

Where a coarse tilth is required, the rotor shield should

be raised as high as possible with the trailing board

folded back. The rotor should always be disengaged

when reversing as well as when turning at headlands.

To stop the machine, raise the clutch lever, and move

the gear lever to the centre (neutral) position. Move

the rotor engagement lever to the "OUT" position and

then release the clutch.

REVERSING

To reverse, pull upthe clutch lever, move the gear lever

to Reverse (this simultaneously operates the safety

interlock) and release the clutch lever. No movement

occurs until the clutch lever is pushed down. Removal

of pressure automatically stops the machine. To dis-

engage levers, pull up the clutch lever and move the

lever to neutral.

IVEVER, UNDER ANY CIRCUMSTAIVCES, TAMPER

WlTH THE REVERSE GEAR LINKAGE. THE INTER-

LOCK MECHANISMISASAFETYDEVICEAND MUST

NOT BE INTERFERED WlTH OR REMOVED.

TURNING

It is often found that the machine is most easily turned

in reverse gear, especially when ground conditions are

very wet and sticky, w~tha considerable amount of

earth adhering to the underside

of

the shield Prov~ded

the rotor is disengaged and the blades are lifted clear of

the ground, the machine can be turned quite eas~ly,

either

in

forward or reverse gear

If

turning appearsto be

difficuit, ctieck that the differe~tiallock is fully dis-

engaged when the rotor lever is pulled back. Adjust-

ment can be made on tt-ie differential lock control rod,

should this not be the case.

HANDLEBAR ADJUSTMENT

The height of the handlet~arscan be adjustedto suit the

operator, bymeansofthealternative holes inthe handle-

bar lugs.

The handlebars can also be offset to one side or the

other, by pressing downthe handlebar positioning lever

to its full extent, and swinging the handlebarstowhich-

ever side is required.

A

hole is provided at each end of

the handlebar slide for positive locking in the required

position

HINTS FOR TOP PERFORMANCE

1.

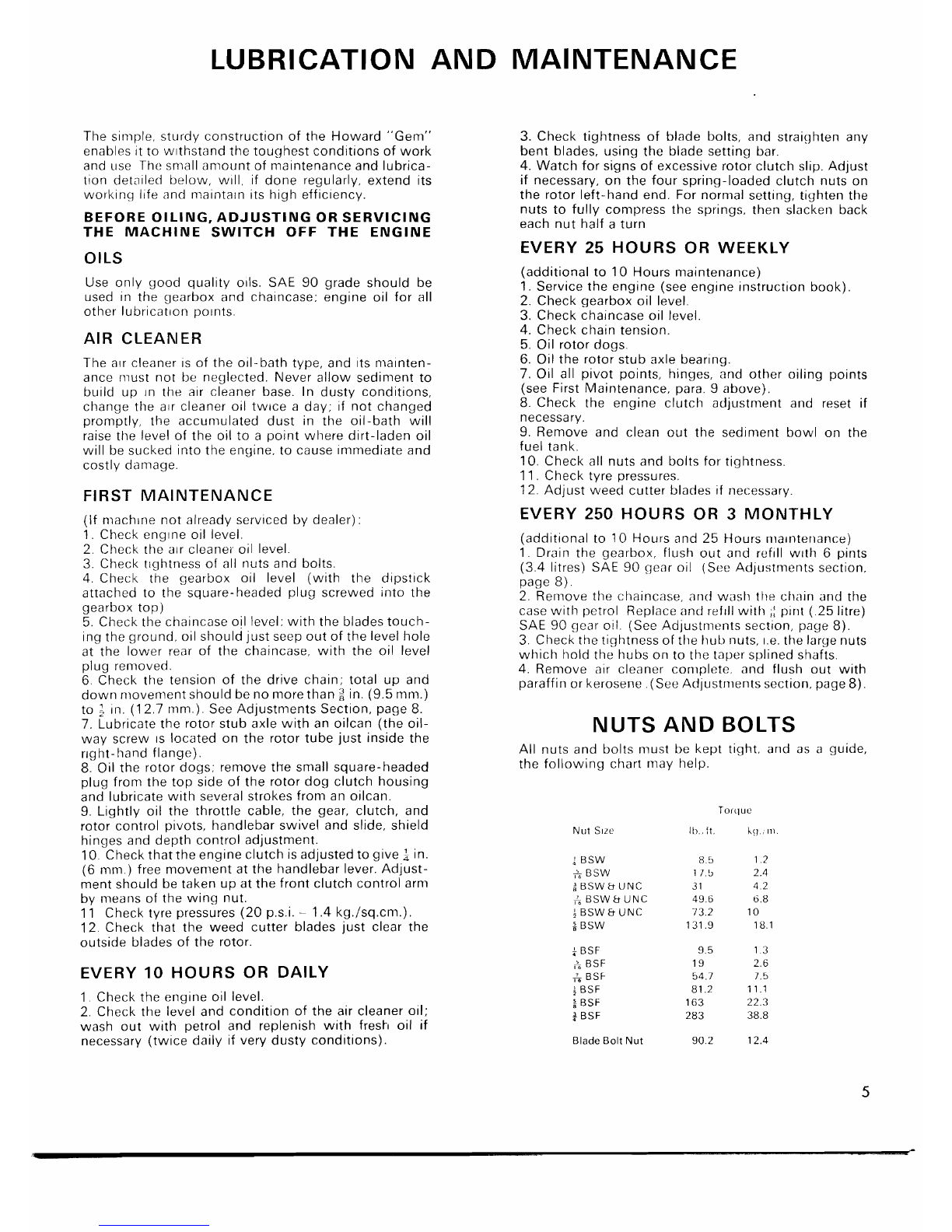

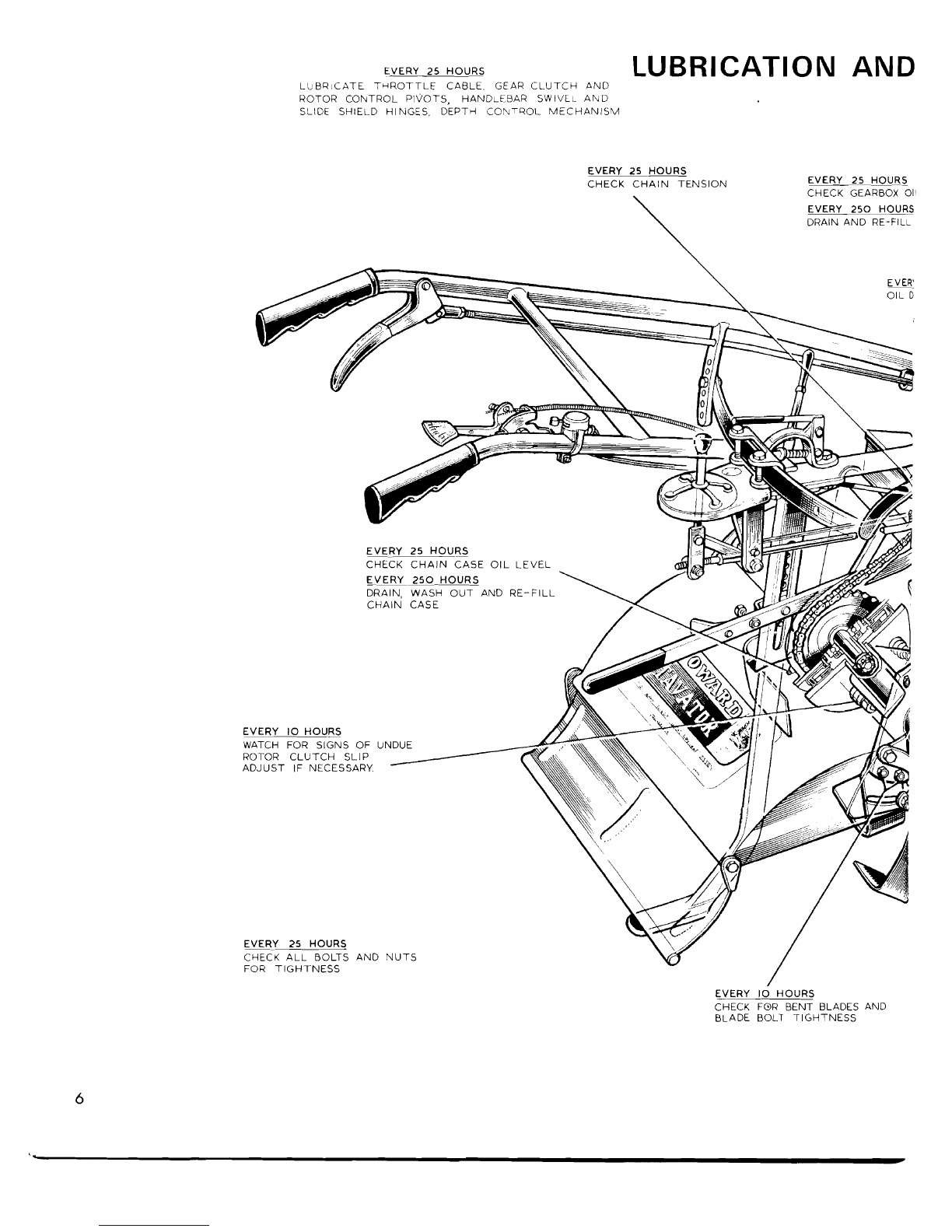

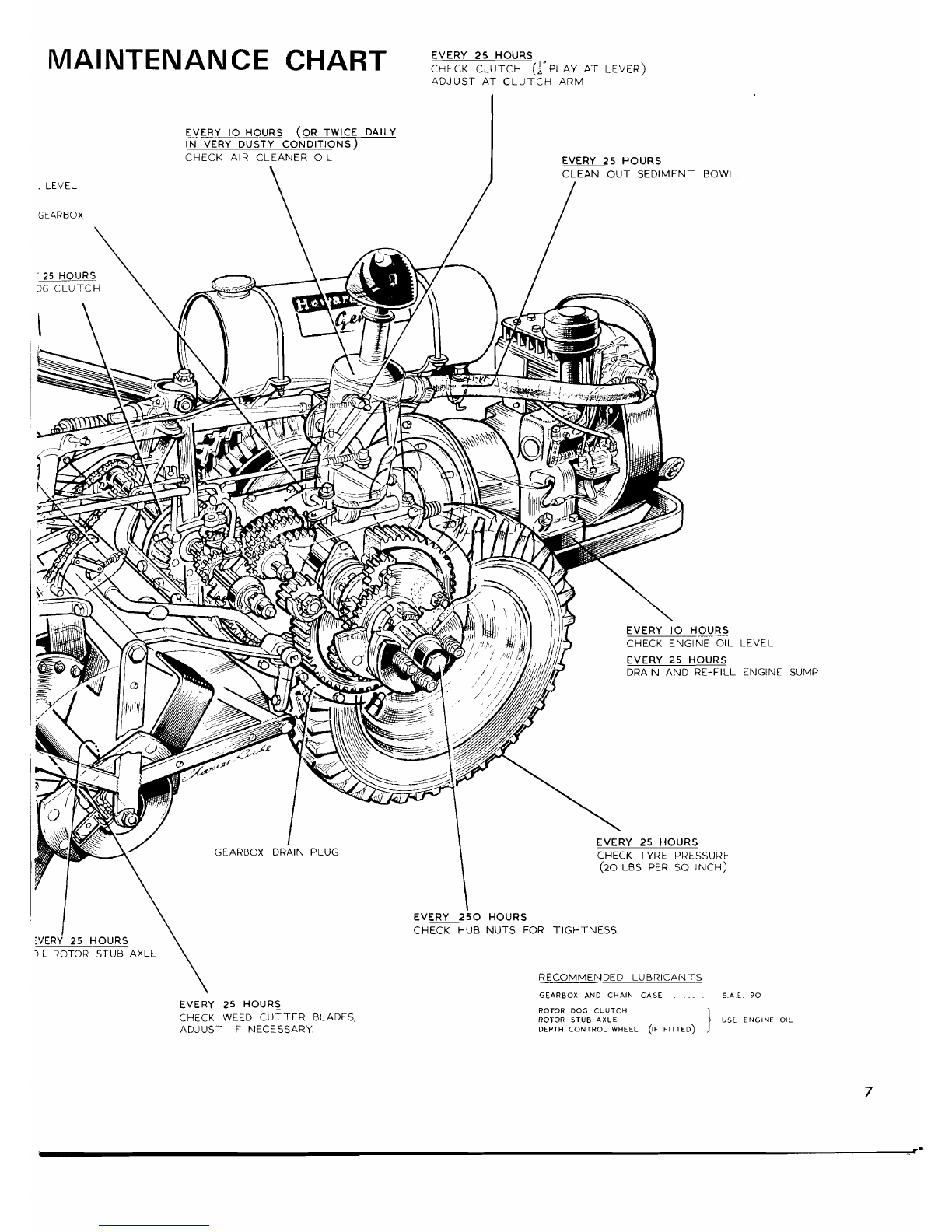

The importance of correct and regular lubrication

cannot be over-stated. Study the lubrication chart on

pages

6

and

7.

2.

Do not neglect air cleaner maintenance.

3.

Always shut the throttle to the idling position when

lifting the clutch lever for engaging or disengaging

gears.

4.

Do not allow the engine to idle at slow speeds for

long periods.

5.

Do not press the handles down should the machine

jump if hitting a stump or similar obstacle; lightly resist

the movement and let the machine right itself. This

applies particularly when working on hillsides in badly

cleared land.

6.

When taking sharp corners, put the rotor out of gear,

lifting the handlebars to help in turning.

7.

Never run the "Gem" with the engine labouring.

Selection of the right gear, and correct depth of work

ensures a constant reserve of engine power.

8.

Always use the clutch in the same way as in a car,

that is, for changing gear only. DO NOT "slip the

clutch" to obtain extra engine speed.

9.

For the first

25

hours, attempt only fairly light work,

to allow the working partsto "bed down".