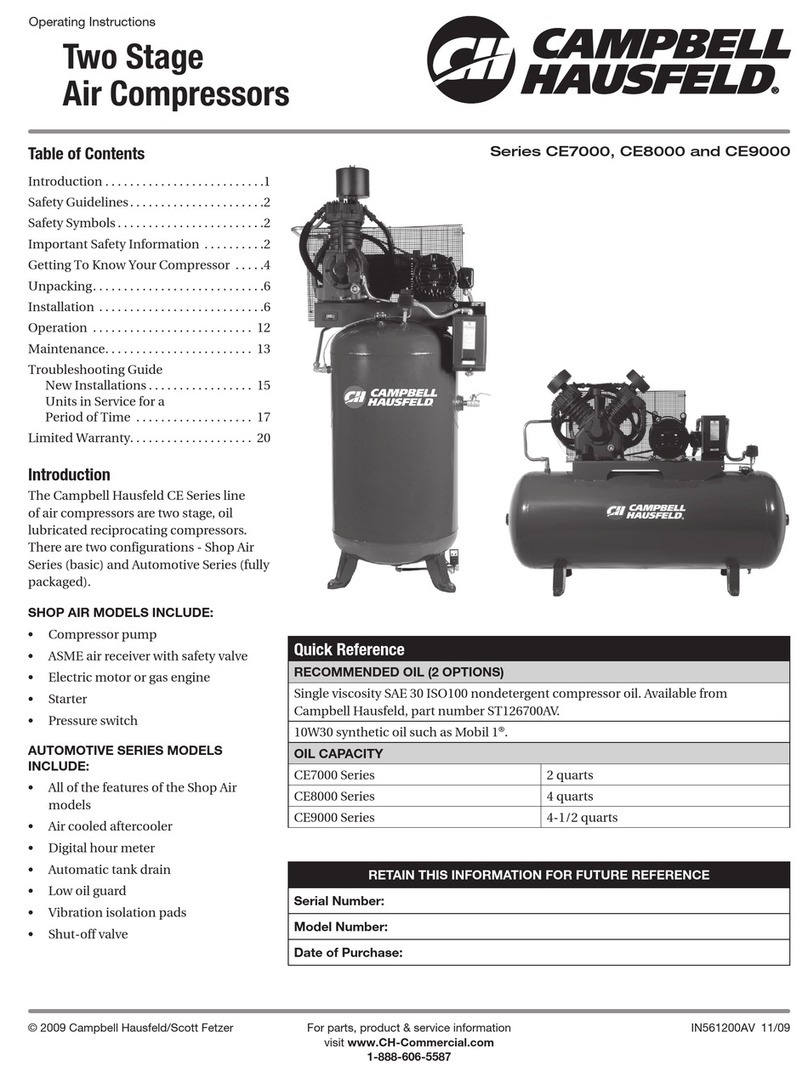

Air Compressors

General Safety (Cont.)

I_WARNINGI

Motors, electrical equip-

ment and controls can

cause electrical arcs that

will ignite a flammable gas or vapor.

Never operate or repair in or near a

flammable gas or vapor. Never store

flammable liquids or gases in the vicini-

ty of the compressor.

Never operate compressor

withoutabeltg.a . This U /

unit canstart automatically _-_

without warning. Personal

injury or property damage could occur

from contact with movingparts.

9. Do not wear Iooseclothing or jewel-

ry that will get caught in the mov-

ing parts of the unit.

Compressor parts may be

hot even if the unit is

stopped.

10. Keep fingers away from a running

compressor; fast moving and hot

parts win cause injury and/or burns.

11. If the equipment should start to

vibrate abnormally, STOPthe

engine/motor and checkimmediate-

ly for the cause. Vibration is gener-

ally an indication of trouble.

12.To reduce fire hazard, keep

engine/motor exterior free of oil,

solvent, or excessive grease.

WARNINGI AnASMecode

ty relief valve with a

setting no higher than the Maximum

Allowable Working Pressure(MAWP)of

the tank MUSThe installedin the air lines

or in the tank for this compressor.The

ASMEsafety valve must have sufficient

flow and pressureratings to protect the

pressurized components from bursting.

The flow rating canhe found in the parts

manual. The safety valve in the intarcool-

er doesnot provide systempro_-tion.

Maximum operat-

ing pressure is 175

psi for two-stage compressorsand 135

-150 psi for single stage compressors.Do

not operate with pressureswitch or pilot

valves sethigher than 175 psi (two-stage)

or 135 -150 psi (singlestage).

13. Never attempt to adjust ASME safe-

ty valve. Keep safety valve free from

paint and other accumulations.

Never attempt to repair or

modify a tank! Welding, |_

drilling or any other mndi- L _ "mE_

fication will weaken the

tank resulting in damage from rupture

or explosion. Always replace worn,

cracked or damaged tanks.

Drain liquid from

INOTICE I tankdaily.

14. Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank regularly and inspect

periodically for unsafe conditions

suchasrust formation and corrosion.

15. Fast moving air will stir up dust and

debris which may be harmful. Release

air slowlywhen draining moisture or

depressurizing the compressor system.

SPRAYING PRECAUTIONS

IAWARNINGI

Do not spray flammable

materials in vldnity of open

flame or near i_'rtioe

sourcesincludingthe compressor unilL

16. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

17. Use a face mask/respi- FA,,.ah- _

rator when spraying

and spray in a well ven-

tilated area to prevent

health and fire hazards.

18. Do not direct paint or other sprayed

material at the compressor. Locate

compressor asfar away from the spray-

ing area aspossibleto minimize over-

spray accumulation on the compressor.

19. When spraying or cleaning with sol-

vents or toxic chemicals, follow the

instructions provided by the chemi-

cal manufacturer.

Installation

IAWARNING]

Disconnect, tag and lock

out power source then

release all pressure from

the system before attempting to

install, service, relocate or perform any

maintenance.

A_--CAUTION] Donotliftormove

unit without appro-

priately rated equipment. Be sure the

unit issecurely attached to lifting

device used. DOnot lift unit by holding

onto tubes or coolers. Do not use unit

to lift other attached equipment.

Never use the

wood shipping

skids for mounting the compressor.

Install and operate unit at least 24"

from any obstructions in a dean, well

ventilated area. The surrounding air

temperature should not exceed 100=F.

This will ensure an unobstructed flow

of air to cool compressor and allow

adequate spacefor maintenance.

Do not locate the

]ACAUTIONI compressoralrlnlet

near steam, paint spray, sandblast areas

or any other source of contamination.

NOTE: If compressor operates in a hot,

moist environment, supply compressor

pump with clean, dry outside air.

Supply air should be piped in from

external sources.

TANK MOUNTING

The tank should be bolted into a flat,

even, concrete floor or on a separate

concrete foundation. Vibration isolators

should be used between thetank leg

and the floor. Model MP345800AJ isola-

tor pads are recommended for horizon-

tal units. Model MP345700AJ isolator

pads are recommended for vertical units.

When using isolator pads, do not draw

bolts tight. Allow the pads to absorb

vibrations. When isolators are used, a

flexible hose or coupling should be

installed between the tank and service

piping.

FAWARNING]

Failure to properly install

the tank can lead to cracks

at the welded jointa and

possible bursting.

PIPING

IAWARNINGI Never use plastic

(PVC) pipe for com-

pressed air. Serious injury or death

could result.

Any tube, pipe or hoseconnectedto the

unit must be able to withstand the tem-

perature generated and retain the pres-

sure. All pressurized components of the

air systemmust have a pressure rating

higher than or equal to the 200 psifor