CPB-435CNH Case and New Holland Combines (without speed multiplier) Camso | 04-17 | 2

1.0 Introduction

This Installation manual was prepared with the latest service information available at the time of

publication. Read the installation manual carefully before doing any service on the

undercarriage(s).

The photos, illustrations, and data used in this manual were current at the time of printing, but

due to possible production change, your installation can vary slightly. Camso reserves the right

make changes as necessary without notification.

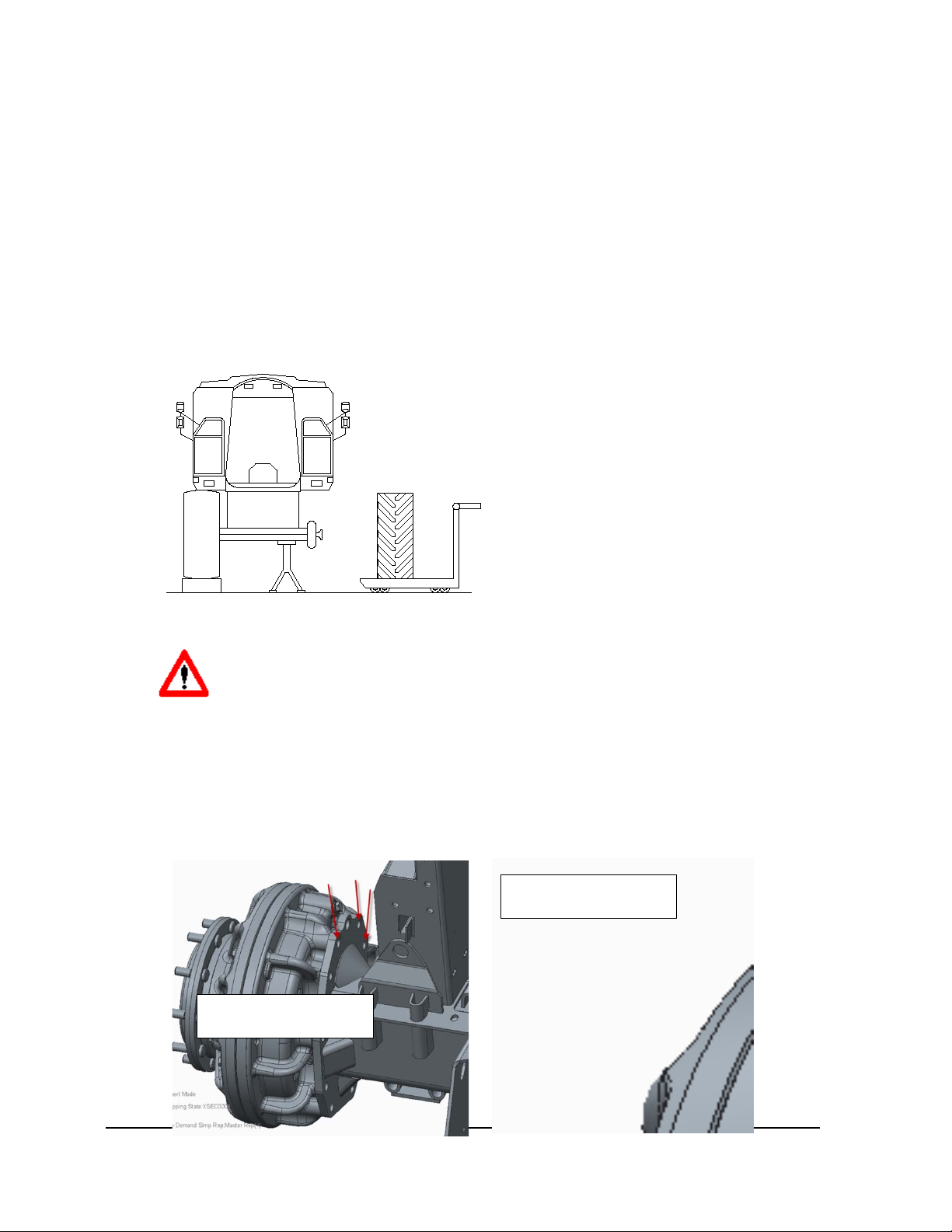

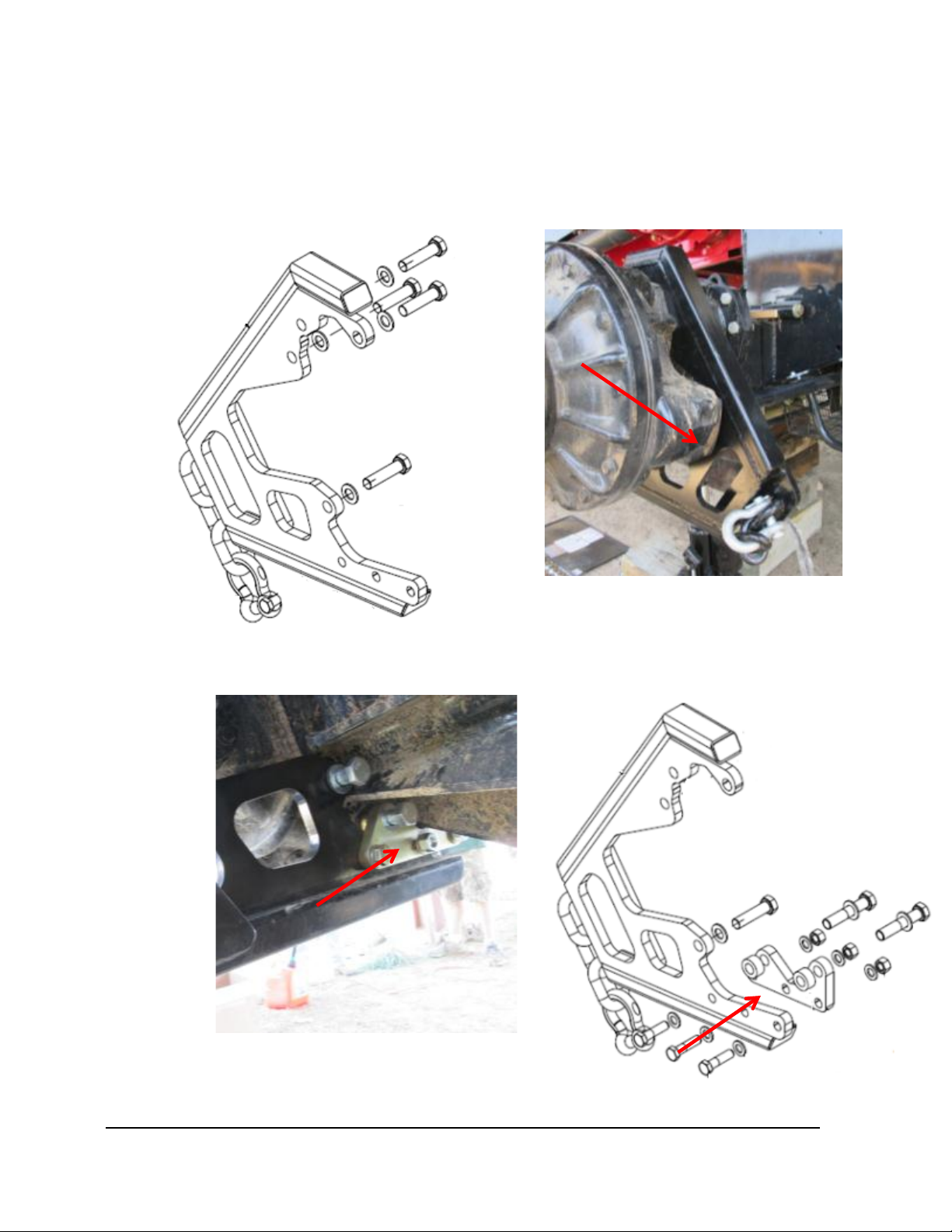

WARNING

Some pictures in this manual show the undercarriage with shields removed

or undercarriage removed from the cart or frame to allow for a better view

of the subject of the picture.

2.0 Important Safety Information

Read and understand this manual, the undercarriage operator's manual, the operation manual

for the equipment the undercarriage is mounted to, and the manual for all attachments before

installing track system onto the machine.

Most personal injuries occurring during equipment operation, maintenance, or repair are caused

by failure to observe basic safety rules and precautions. In most cases, an injury can be avoided

by recognizing hazardous situations before an injury occurs.

A person must be alert to potential hazards. This person should also have the necessary training,

skills and tools to perform these functions properly.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

Not every possible circumstance that might involve a potential hazard can be anticipated. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool,

procedure, work method or operating technique that is not specifically recommended by Camso

is used, you must satisfy yourself that it is safe for you and for others.

You must also make sure that the product will not be damaged or be made unsafe by the

operation, lubrication, maintenance or repair procedures that you choose. The information,

specifications, and illustrations in this publication are on the basis of information that was

available at the time that this publication was written.

The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service that is given to the product.

Obtain the complete and most current information before you start any job. Camso dealers have

the most current information available.

WARNING

When replacement parts are required for this product Camso recommends

using Camso replacement parts. Failure to heed this warning can lead to

premature failures, product damage, personal injury or death.