C&S CSDPR-V2-300 User manual

current Protection Relay

CSDPR-V2-300

R37QRG000132

QuickReferenceGuide

Q

R

G

This QRG will help you step-by-step installation, operation and programming

procedure. Please go through all the instructions carefully prior to implementing.

C&S Electric Limited

Introduction

In the family of protection relay, CSDPR-V2-300 is numeric multi powered Over-current

relay specially designed for ring main units & feeder protection. It combines the following

functions in one unit:

u Over current, Short Circuit, Earth Fault & Earth Fault High set protection

u DEFT & Inverse characteristics for O/C and E/F individually selected for

phase & earth fault

u Wide operating ranges of the auxiliary supply voltage (AC/DC)

u Remote trip *

uSwitch on to fault (SOTF) protection

u Remote protection block input DI*

u Potential pulse output for direct triggering the circuit breaker coil

u Potential free alarm contacts available

u Unbalance/ Asymmetric protection

u Circuit breaker failure protection

u Harmonic blocking (via DFT Filter) to avoid any unwanted tripping

u Two sets of setting groups

u Last 5 Fault and 10 Event record with Time stamp

u RS-485 Modbus

u USB port for PC / Laptop interface

Design

Relay will get energized from any of the following available sources:

u Aux. supply

u CT current

u Internal battery

u USB port

Relay will operate its trip contacts only when CT current is present or Aux. supply is available,

with other power sources, only the relay display/HMI will be available.

In the absence of Aux supply/Battery voltage/USB, LCD will get energized, if CT current is

10% of rated current or above. Trip coil will be operated, if CT current in single phase is at

least 20% of rated current or 15% of rated current in three phases. Relay is not powered from

Earth CT, so for earth fault protection, phase current is mandatory.

The disposal of our products and possible recycling of their components after

decommissioning has to be carried out by an accredited recycling company or

the products/components must be taken to applicable collection points. Such

disposal activities must comply with all local laws, guidelines and

environmental specifications of the country in which the disposal is done.

Our products and batteries must not be disposed of as household waste. For disposing

batteries it is necessary to observe the local national/international directives.

According to national legislation, penalties may be charged for incorrect disposal of

such waste.

By disposing of these products correctly you will help to save valuable resources and prevent

any potential negative effects on human health and the environment.

Disposal

02

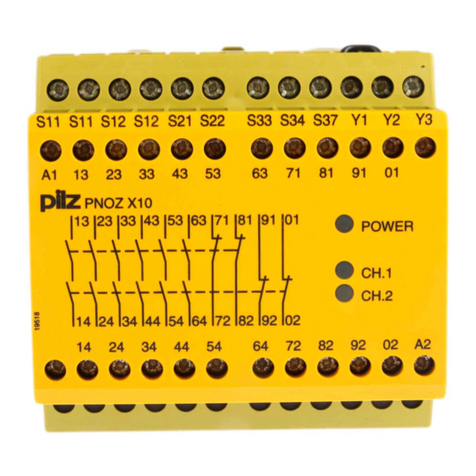

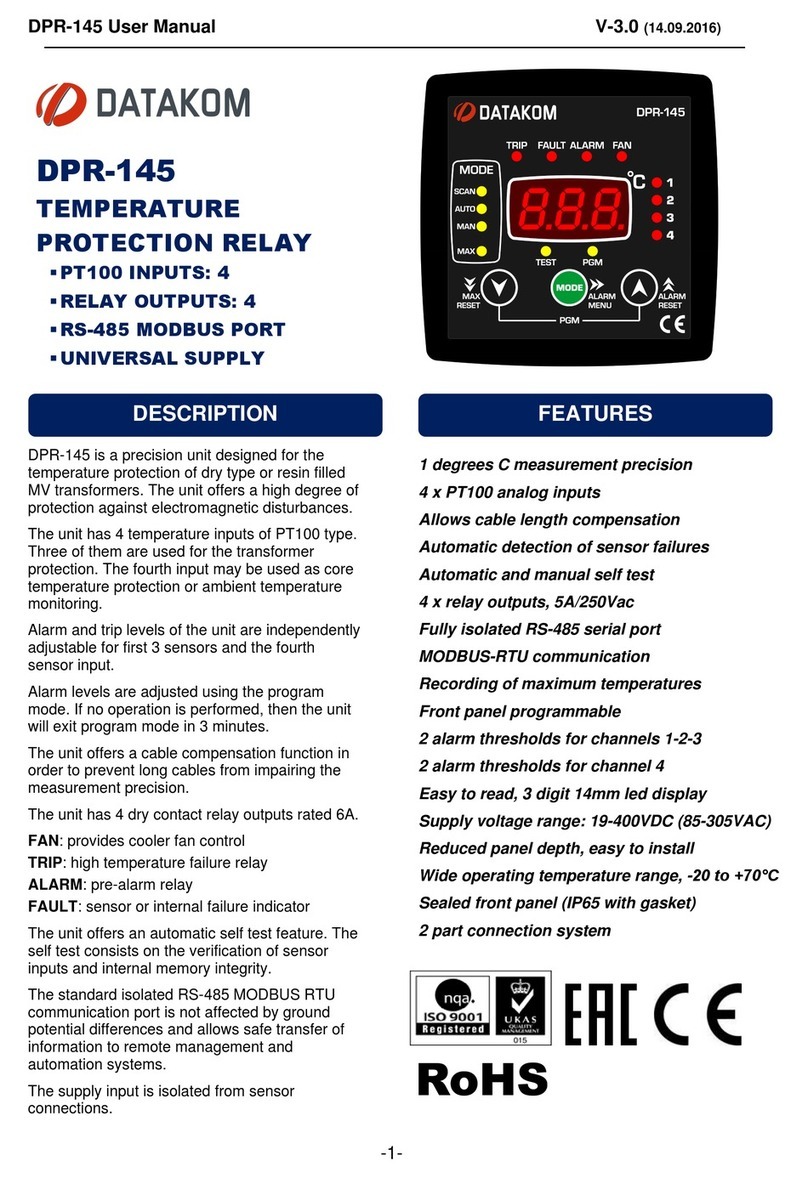

Front Interface of the Relay

Description A : This key is used to ON the LCD when available source is Aux Supply, CT current or USB port)

Description B : This key is used to ON the LCD when available source is only Battery.

RESET

ON READY/HLTHY

TRIP

PICKUP

E3LL 1L 2 CBFPTCS

CSDPR-

V

2

ENTER

R M U R O T E C T I O NPE L A YR

Alpha Numeric LCD

Up Scroll /

Decrement Key

Enter Key

U S B port for P C /

Laptop communication

Fault Reset Key

(Manual Reset on

pressing for 2 sec)

See Description B

MHT Ready /

MHT Ready LED

Down Scroll /

Increment Key

Battery Cover

(Remove battery cover

to change the appropriate

battery)

See Description A

L1 phase for pickup & Trip indicator

L2 phase for pickup & Trip indicator

L3 phase for pickup & Trip indicator

Earth fault for pickup & Trip indicator

Common pickup for fault

Trip Status of Relay

Trip circuit supervision

CBFP external breaker failure indicator

TRIPE PICKUP3L

L

1L2 TCS CBFP

*

03

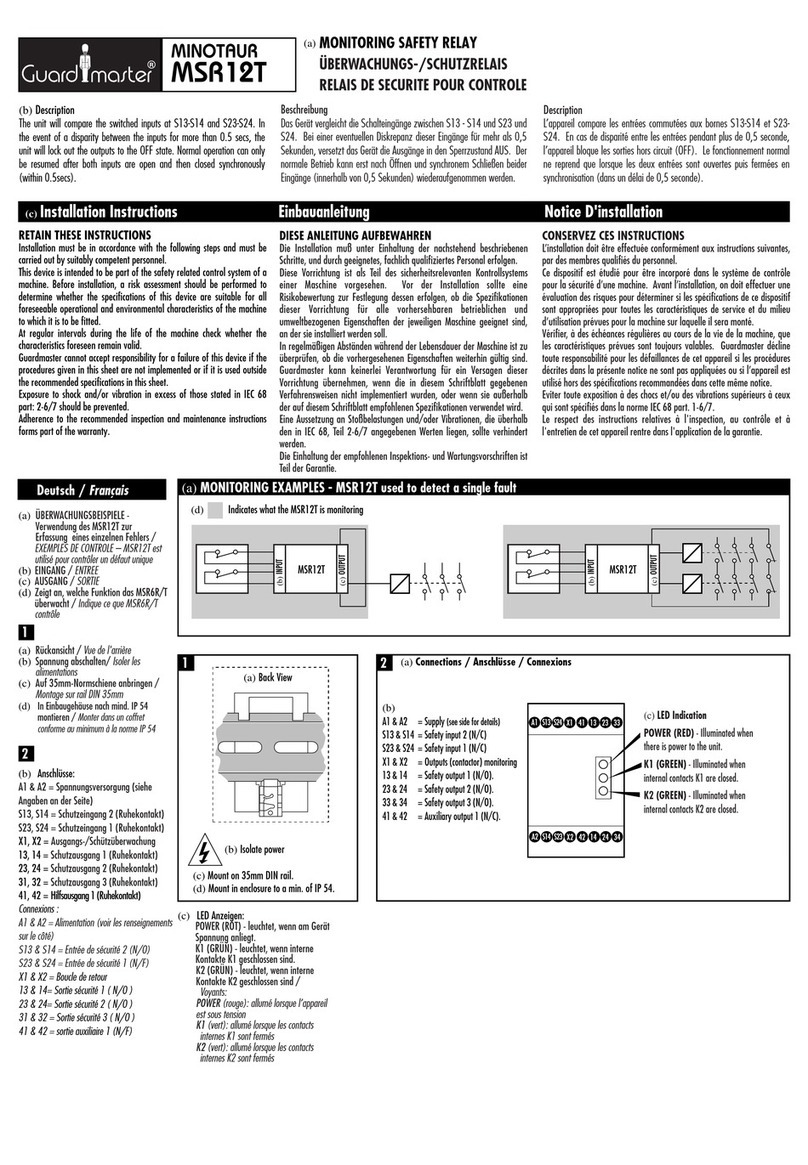

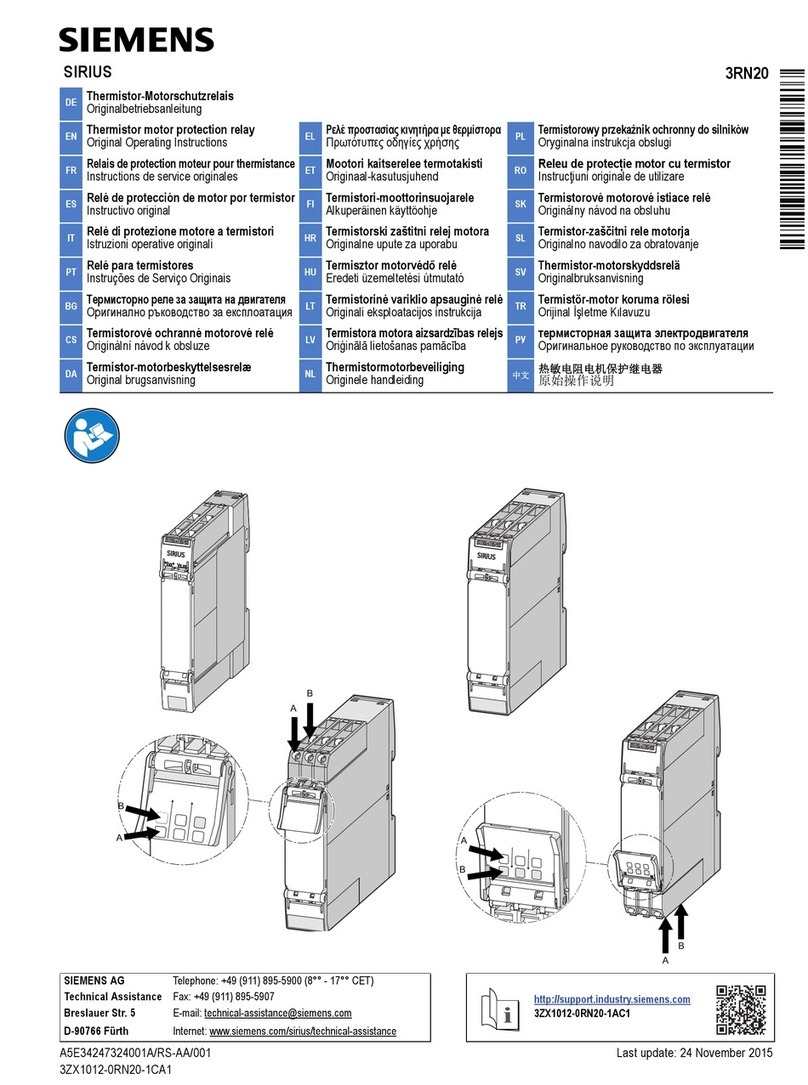

Conn. Diagram (TCS Model) *

NOTE: While doing the HV test, don`t connect the MHT terminal (C4-C5),

as internal capacitor bank could be in charged state & it can harm the circuitry.

In TCS model : Remote Trip & Remote Block DI will not be available.

L1

L1

L2

L2

L3

L3

P1

P1

P2

P2

S1

S1

S2

S2

IL1

IL1

E1

E1

E2

E2

IL3

IL3

E5

E5

IL2

IL2

E3

E3

E7

E7

E8

E8

E9

E9

E10

E10

E4

E4

E6

E6

Ie

Ie

A9

A9

A10

A10

A11

A11

DI-2

DI-2

DI-(Comm)

DI-(Comm)

DI-1

DI-1

* CB Open

* CB Close

B1

B1

B3

B3

B2

B2

B4

B4

Flag Indicator

Flag Indicator

Trip Coil

Trip Coil

TF+

TF+

TC-

TC-

TF-

TF-

TC+

TC+

DO-1

DO-1

A7

A7

A8

A8

DO-2

DO-2

A5

A5

A6

A6

Latch

Latch

Operates with

only Aux supply

Operates with

only Aux supply

DO-3

DO-3

A3

A3

A4

A4

DO-4

DO-4

A1

A1

A2

A2

B8

B8

B7

B7

A

A

RS 485

RS 485

B

B

B6

B6

COM

COM

COM

COM

COM

COM

COM

COM

NO

NO

NO

NO

NO

NO

NO

NO

Aux Supply

A13

Aux-P Aux-N

A14

Aux Supply

A13

Aux-P Aux-N

A14

* Remote Block

* Remote Trip

Conn. Diagram (Standard Model without TCS) In TCS model : Remote Trip &

Remote Block DI will not be available.

P1

P1

P2

P2

S1

S1

S2

S2

P1

P1

P2

P2

S1

S1

S2

S2

04

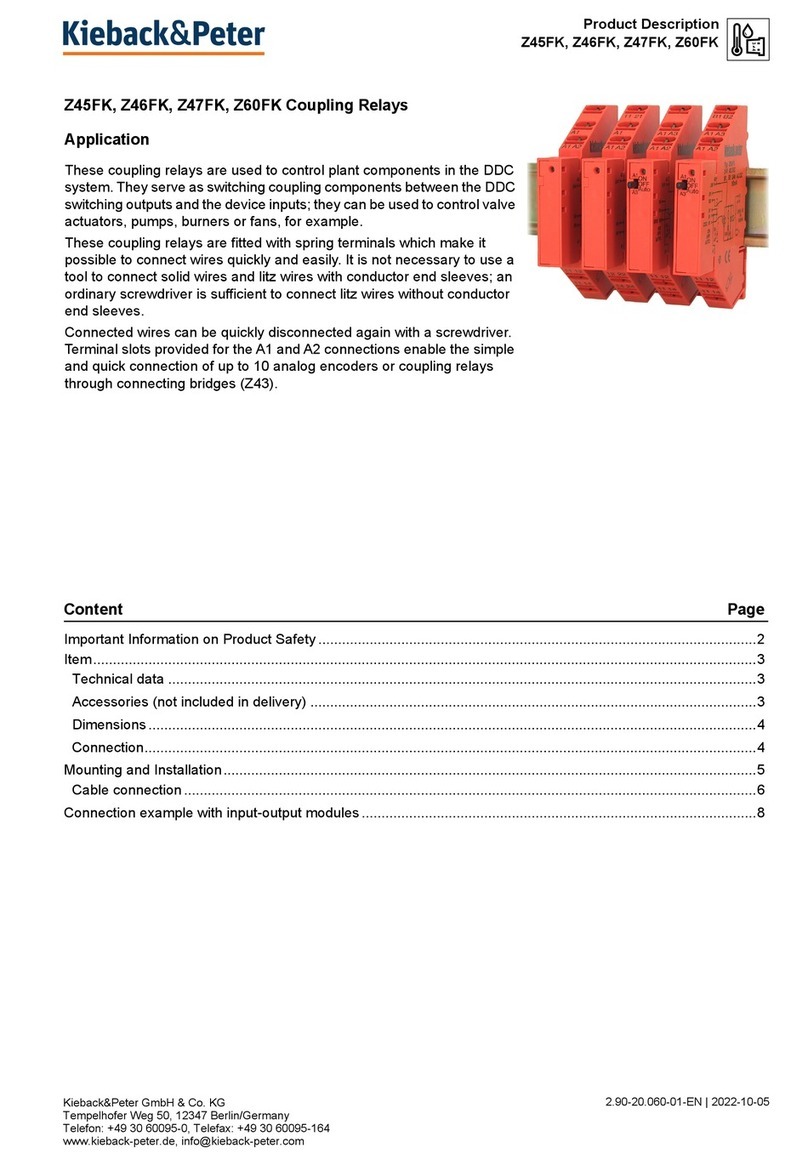

Dimension Details (All the dim. are in mm)

Front View

Side View

110.0

158.0

167.8

118.0

128.0

158.0

167.8

Specification Table of the Relay

* ordering based

Function ANSI CSDPR-V2-300

3 Phase Over current protection 51 ü

3 Phase Instantaneous protection 50 ü

Earth time Over Current 51N ü

Earth time Instantaneous Over Current 50N ü

Circuit Breaker Failure protection 50BF ü

Switch onto fault SOTF ü

Trip circuit supervision * 74TC ü

Fault Record – 05

Event Record – 10

LCD Display – 16x2 Alpha Numeric

Digital Input *

Remote Trip* / CB Close – ü

Remote Block* / CB Open – ü

Digital Output – ü

Pulse Output – ü

Powered Nature – CT powered

Aux. powered

Front Communication – ü

Rear Communication (RS-485) – ü

Battery Backup – ü

05

Back Terminal view (TCS model)

Back Terminal view (Standard model without TCS)

RemoteBlock(DI-2)

RemoteTrip(DI-1)

DI-Common

06

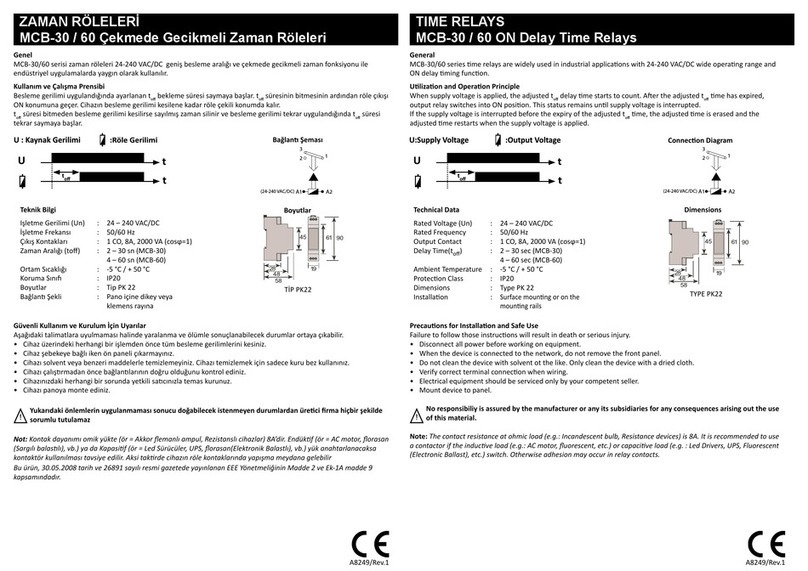

Remove the Battery cover

by twisting it on the left side

as shown in the Left image.

Close the Battery cover by

twisting it on the right side

as shown in the Left image.

Remove the Sticker placed

on Battery to start the unit

with Battery.

Replace the prescribed

1/2 AA size suitable battery

with the new one.

Battery changing Procedure Photograph shown here for have an idea only

07

Technical Data

Rear (RS-485) Communication Setting

Parameter Display Setting Range

Slave Address SLV Add 1-32

Baud Rate BD Rate 9600/19200

Parity Parity NONE/EVEN/ODD

General Data

Front (USB) Communication

Front Port: CSE protocol with CSE LIVELINK on mini USB cable type A/A

Measuring Input

Rated data Rated current IN (1A)

Frequency FN: 50/60 Hz

Measurement Measurement of Phase / Earth current starts from 5%

Rated auxiliary Universal L: (18V - 60V DC)

voltage UH H: (85V - 260V AC /

110V to 300V DC)

Rated supply for Normal voltage UN L: (18V - 60V DC)

DI input H: (85V - 260V AC /

110V to 300V DC)

Power consumption

of Aux supply Quiescent approx. 3W Operating approx. 6W

Dropout pickup ratio > 95 %

Phase / Earth VA Burden : (2.5VA @ Rated Current)

08

Accuracy

Tripping times DMT : + 5% of the setting value or +40 mSec

with pre-fault IDMT : Accuracy as per IEC-255-3 (2xIs to 20xIs)

For VINV / NINV/RI : + 5% or + 40 mSec

For LINV/EINV/HV-Fuse : + 7.5% or + 60 mSec

Pickup accuracy +5% or +10mA

Boot-up time in < 100 mSec; (Event recorder enabled : 20mSec extra)

self powered mode

Output Contact (Relay Specs)

Number of relays 4

DO contacts (DO: 1, 2) DO1 & DO2 are user programmable

configurable & available for I>, I>>, le> & Ie>>, CBFP,

only with Auxiliary supply Unbalance (U0>), Remote DI, all faults

Relay contacts: 3, 4 Latch type of DO common for all

(available in all models) protection trip

Max. breaking capacity 1250VA / 150W resistive

500VA / 90W inductive

Max. breaking voltage 400V AC, 125 VDC

Max. continuous AC current 5A

Thermal Withstand Capacity

Thermal withstand Continuously 2.5A

capacity 10s 15A

for In=1A 1s 80A

09

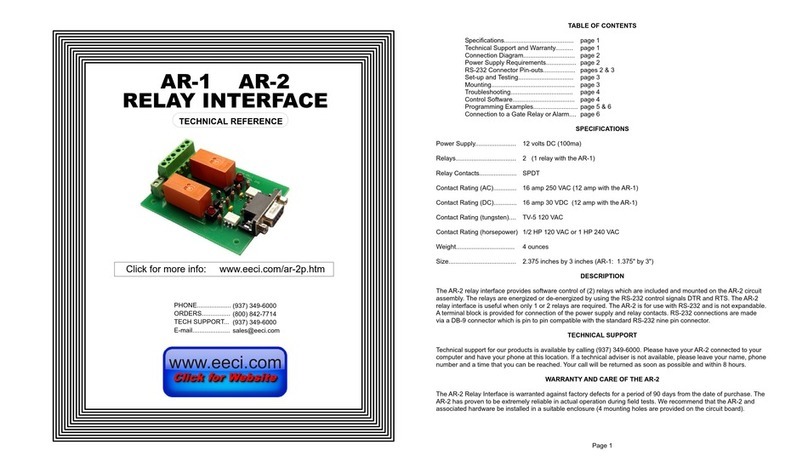

Inverse Graph Representation

Inverse Time characteristics

10

Default First Screen

Two group of Protection Setting are available in CSDPR-V2 relay. User can select

One Group as Active Group. For setting below are simple steps for configuration:

Default Password for settings : “ 4-Times Enter Key”

MAIN DEFAULT SCREEN PAGE:

The very first Screen of the HMI shows the Measured Primary Current for all the

phases based on CT ratio.

L1 : 0000.0 A

L2 : 0000.0 A

<Menu 1>

(EDIT/VIEW PARAMETERS)

By using

the

scroll keys

select the

desired

menu and

press

ENTER.

Press Key

FACTORY MODE Setting are not for the users.

How to do Settings

*

Note : - * Menu Model Dependent

# / #EDIT VIEW

< > : For Active Group Selection of ParameterGROUP SELECT

< > : Protection Related Parameter MenuPROTECTION

< > : Cold Load Protection MenuCOLDLOAD PRT

< > : Fault Record MenuFAULT RECORD

< > : Event Record MenuEVENT RECORD

< > : Programmable Relay Assignment MenuDO ASSGNMNT

< > : Programmable Relay Reset MenuDO RESET

< > : Trip TypeTRIP TYPE

< RST TRIP CNT > : Reset Trip count Menu

< > : Display Options MenuDISPLAY OPTN

<BATTRY STATS > : MenuBattery Status

< > : Output Trip Test MenuTRIP TEST

< > : Communication 485 MenuCOMMN SETTNG RS

< > : Load Default MenuLOAD DEFAULT

< > : Clock Setting MenuEDIT RTC

< > : Password Change MenuCHNGE PSWORD

< > : Factory Setting MenuFACTORY MODE

< > : Relay Version MenuRELAY VERSON

← BACK

11

# GROUP SELECT #

ACTIVE-GRP : GRP1

←BACK

On selecting GROUP SELECT by pressing ENTER

key, user can change the active group by using

ENTER and then scroll key.

Press Enter and If the user selects the YES option

then it will ask to enter the correct password or else to

go to the previous menu by selecting the other

options by pressing ENTER key.

From Menu-1:

From Menu-1: # PROTECTION #

CTRatio : 0001 : CT Ratio for primary current display

Frequency : 50Hz : Frequency characteristic

PhaseCh : DEFT : Phase over-current trip characteristic

EarthCh : DEFT : Earth over-current trip characteristic

l> : 0.20xIn : Over-current Pickup

ti> : 0.01 : TMS Over-current Setting

t> : 0.1s : DEFT Trip Time

l>> : 0.5xIn : Short Circuit Protection

t>> : 0.03 : DEFT Trip timing for SC Protection

Ie> : 0.05xIn : Earth Over-current Pickup

tie> : 0.01 : Inverse Trip Time

te> : 0.05s : DEFT Trip Time

Ie>> : 0.01xIn : Earth High-set Pickup

te>> : 0.05 : DEFT Trip timing Earth High

SOFTpk : DISABLE : SOTF pickup setting

Unbalnc : 5% : Unbalance

tUnblnc : 0.50s : Unbalance DEFT Trip Time

CBFP : YES : CBFP Supervision Time

tCBFP : 0.15s : CBFP Supervision Time

td_TCS : 2.00s : TCS Trip Time

←BACK

O n s e l e c t i n g

P R O T E C T I O N b y

pressing ENTER key.

User can see the list of all

the protection setting

parameter by using the

scroll keys.

Press ENTER to select

the desired Parameter &

use SCROLL keys to

Edit the selected one.

If the user change any of

the setting, It is required

to save the changes by

pressing ENT ER key

and than selecting YES

option, after that entering

the correct password to

save the setting or else

to go to the previous

menu by selecting the

o t h e r o p t i o n s & b y

pressing ENTER key.

12

From Menu-1:

On selecting COLD LOAD PRT by pressing ENTER

key, User can see the list of all the parameter by using the

scroll keys.

Press ENTER to select the desired Parameter & use

SCROLL keys to Edit the selected one.

If the user change any of the setting, It is required to save

the changes by pressing ENTER key and than selecting

YES option, after that entering the correct password to

save the setting or else to go to the previous menu by

selecting the other options & by pressing ENTER key.

On selecting EVENT RECORD, by pressing ENTER

key, Event no. screen will appears. By using ENTER &

Scroll keys select the desired Event no. for its details. To

go to the previous menu press BACK key.

On selecting FAULT RECORD, by pressing ENTER

key, Fault no. screen will appears. By using ENTER &

Scroll keys select the desired Fault no. for its details. To

go to the previous menu press BACK key.

#COLD-LOAD-SET#

ColdLdPrt : DISABLE

tCldLoad : 00.10s

←BACK

# FAULT RECORD #

<FAULT NUMBER>

<ERASE FAULTS>

←BACK

# EVENT RECORD #

<SELECTION>

<EVENT NUMBER>

<ERASE EVENTS>

←BACK

From Menu-1:

From Menu-1:

From Menu-1:

On selecting DO ASSGNMNT by pressing ENTER key,

User can see the list of all the parameter by using the

scroll keys. Press ENTER to select the desired

Parameter & use SCROLL keys to Edit the selected

one. If the user change any of the setting, It is required to

save the changes by pressing ENTER key and than

selecting YES option, after that entering the correct

password to save the setting or else to go to the previous

menu by selecting the other options & by pressing

ENTER key.

# DO ASSGNMNT #

I> : DISABLED

I>> : DISABLED

Ie> : DISABLED

Ie>> : DISABLED

Unbaln : DISABLED

CBFP : DISABLED

TCS : DISABLED

AllFlt : DISABLED

SOTF : DISABLED

←BACK

On selecting DO RESET by pressing ENTER key, User

can see the list of all the parameter by using the scroll

keys. Press ENTER to select the desired Parameter &

use SCROLL keys to Edit the selected one.If the user

change any of the setting, It is required to save the

changes by pressing ENTER key and than selecting

YES option, after that entering the correct password to

save the setting or else to go to the previous menu by

selecting the other options & by pressing ENTER key.

# DO RESET MODE #

DO 1 : AUTO

DO 2 : AUTO

←BACK

13

From Menu-1:

# TRIP TYPE #

TripO/P : TRIP-COIL

←BACK

Reset Count....?

YES NO CANCEL

# DISPLAY-OPTION #

MODE : AUTO OFF

←BACK

On selecting TRIP TYPE by pressing ENTER key, User

can see the list of parameter by using the scroll keys.

Press ENTER to select the desired Parameter & use

SCROLL keys to Edit the selected one.

If the user change any of the setting, It is required to save

the changes by pressing ENTER key and than selecting

YES option, after that entering the correct password to

save the setting or else to go to the previous menu by

selecting the other options & by pressing ENTER key.

On selecting RST TRIP CNT by pressing ENTER key,

User can Reset the Trip count by selecting the YES

option or else comes out from the menu by selecting the

other option.

On selecting DISPLAY OPTN by pressing ENTER key,

User can see the list of parameter by using the scroll

keys.

Press ENTER to select the desired Parameter & use

SCROLL keys to Edit the selected one.

If the user change any of the setting, It is required to save

the changes by pressing ENTER key and than selecting

YES option, after that entering the correct password to

save the setting or else to go to the previous menu by

selecting the other options & by pressing ENTER key.

From Menu-1:

From Menu-1:

# TRIP TEST #

LED/DO TEST

BREAKERTEST

LATCHRESET

←BACK

# BATTERY STATUS #

BATTERY : OK

←BACK

On selecting BATTRY STATS by pressing ENTER

key, User can see the status of the Battery, whether it

is OK or NOT.

On selecting TRIP TEST by pressing ENTER key,

User can see the list of parameter by using the scroll

keys.

Press ENTER to select the desired Parameter & use

SCROLL keys to perform the test.

If the user selects any of the option it will ask to

continue the Test, If the user selects the YES option

then Right/Left key are required to press to perform

the Test, else select other option and press enter to go

to the previous menu .

From Menu-1:

From Menu-1:

14

From Menu-1:

On selecting CHNGE PSWORD Menu by pressing the

ENTER key, user will ask to enter the password. If the

user entered the correct password the next screen will

ask to Enter the New Password after that re-enter the

password for confirmation. If the password changed

successfully, it will flash password change message.

Enter Passwrd

New PASSWORD

Re-PASSWORD

SUCCESSFUL .!

PASSWD CHGD

From Menu-1:

# COMMN SETNG #

SLAVE ADD : 01

BAUDRATE : 9600

PARITY : NONE

←BACK

On selecting COMMN SETTING by pressing ENTER

key, User can see the list of all the parameter by using the

scroll keys.

Press ENTER to select the desired Parameter & use

SCROLL keys to Edit the selected one.

If the user change any of the setting, It is required to save

the changes by pressing ENTER key and than selecting

YES option, after that entering the correct password to

save the setting or else to go to the previous menu by

selecting the other options & by pressing ENTER key.

# EDIT RTC #

HOUR : 11

MIN : 26

SEC : 59

DATE : 23

MONTH : 08

YEAR : 2019

←BACK

On selecting EDIT RTC Menu, user can set the Date,

Month Year Day, Hour, Minute, Second by using the

S c r o l l k e y s .

Press ENTER to select the desired Parameter & use

SCROLL keys to Edit the selected one.

If the user change any of the setting, It is required to save

the changes by pressing ENTER key and than selecting

YES option after that entering the correct password to

save the setting or else to go to the previous menu by

selecting the other options & by pressing ENTER key.

CSDPR-V2-300-D

-L/H-P-T

Ver:V1.0.00.02

DN:220819

←BACK

From RELAY VERSION MENU:

On selecting RELAY VERSION Menu, by pressing

Enter key, it will show the screen.

User can see the relay information by using the scroll

keys. To go to the previous menu press BACK key.

Enter Passwrd

LOAD DEFAULT

Saving .........

On selecting LOAD DEFAULT menu by pressing

ENTER key, User will ask to Enter the correct password.

If the user enter the correct password, the default values

of the relays will restored.

From Menu-1:

From Menu-1:

15

C-60, Wing-A, Phase-II, Noida-201 305, Dist: Gautam Budh Nagar (U.P) INDIA Phone : +91-120-38748 00 / 01

C&S Electric Ltd.

(Protection & Measurement Devices)

For further information, please contact:

1800 572 2012

Technical Question or After-sales Service

Customer Center Quick Response

Service, Excellent Technical Support

Wrong measuring

& tripping values

Se t t i n g a r e n o t

g e t ti ng s a v e &

changed

Wrong connection/

Wrong CT Ratio

Wrong polarity of CT

Relay is in Trip/

Pickup state

Check the w iring as per

diagram.

Relay will not allow changing

its setting unless it is in

healthy state. There should

not be any pickup & present

fault should be

acknowledged. Press Reset

button & clear the entire fault.

Cause of Problem

Problem Remedy

Trouble Shooting Points

Digital outputs are

not operating

Aux Supply is not connected Two Digital outputs (Relays)

work only in presence of

Auxiliary supply. To recheck

the Digital output operation,

Go to Trip Test Menu, Enter in

the <LED/RLY TST> option &

test the Relays.

Tripping coil not

operating

W r o n g c o n n e c t i o n /

I n s u ff i c i e n t c u r r e n t t o

generate energy for Trip

1) Wiring to be checked.

2) Check whether the coil is

healthy.

3) Check the front Trip Ready

G r e e n L E D . I t s h o u l d

continuously blink. If it is not

blinking then relay can`t trip

the coil (insufficient energy

because of low current).

4) Use Trip Test to verify the

connection & relay operation.

Issue Date : 11.06.20, Rev. No : 05, Rev. Date : 18.05.22

Relay is not getting

on through Battery

1) Low Battery

2) Battery Seal is applied

1) P o we r O N t he re l ay

through Aux supply / current /

USB & go to battery status

menu, If Battery is low then it

display the Battery status

N O T O K . R e p l ac e t h e

battery

2) Check whether Battery

Seal is removed & both the

batteries are inserted with

proper polarity.

16

Table of contents

Other C&S Relay manuals