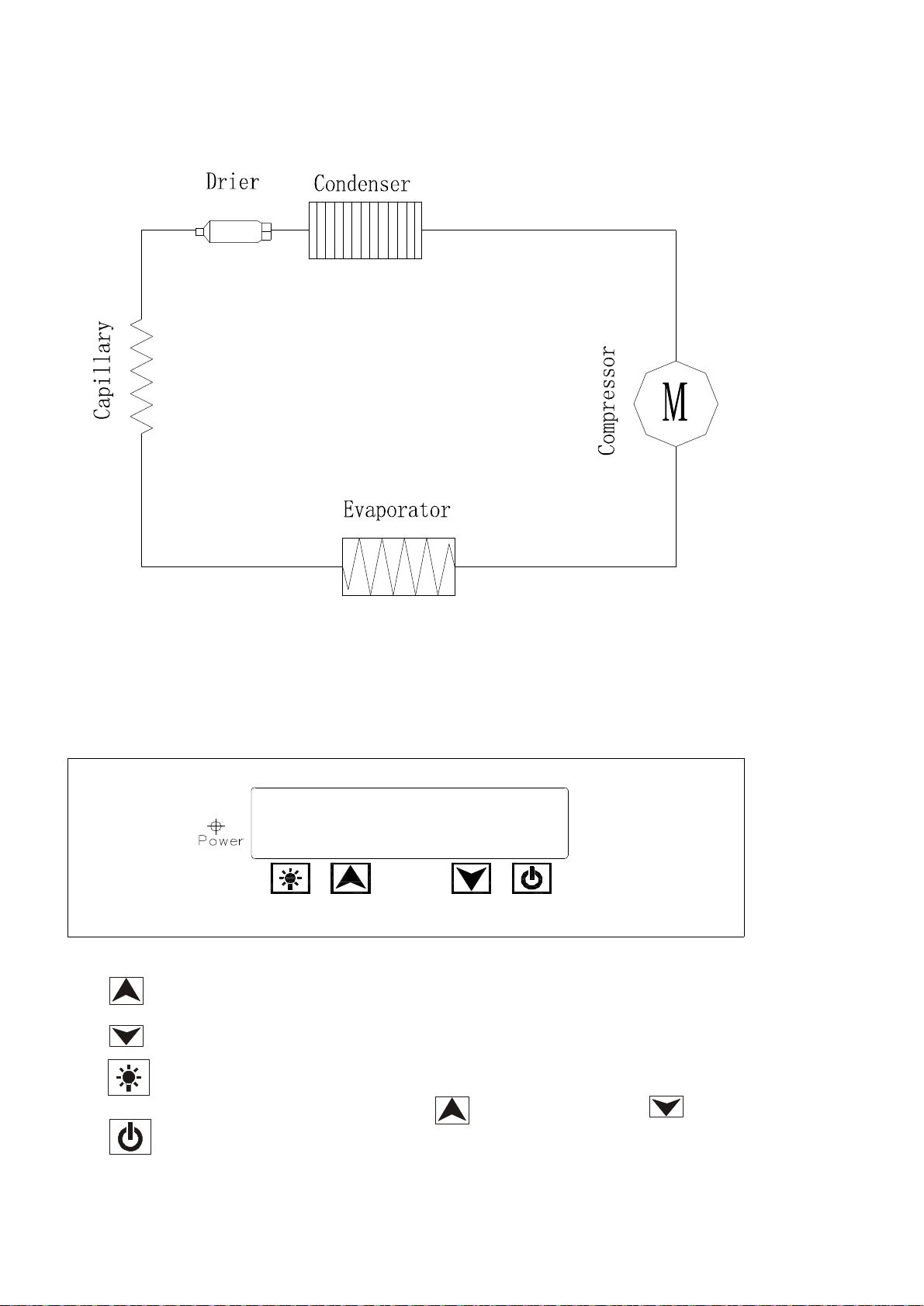

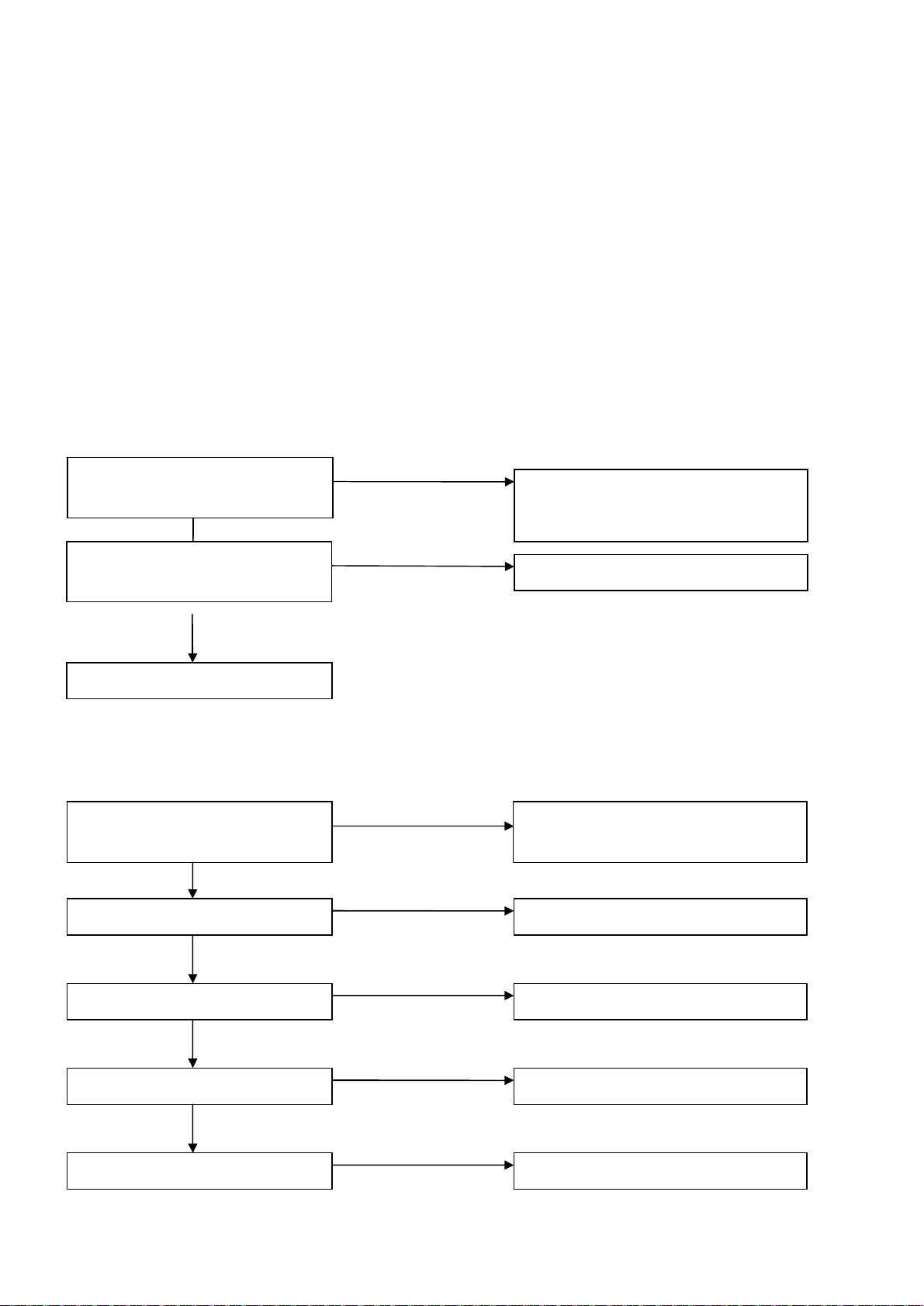

If yoususpectthatthecontrolsystemfault, youcanstartheself-checkmodebyfollowingbelow:

1>.Poweronthewinecooler,it will beeponesound,thewinecoolerstar,within10 secondsafterit start,

press the ‘▲’and‘▼’atthe same time and holding, threebeepwillsound,thesystems enter

self-check mode.

The power indication light on.

The readouts show the actual temperatures.

The heater on and last for ten seconds

The LED light on.

All of the inner and outer fans running.

No responsewhen touch the controlled button.

2>.If all tallywithabovedescription,thepartsarenormal.If anypartfail,checkthefailedpartand the

correspondingwiringandconnection,ifthewiring andconnection isingoodcondition,replacethepartand

checkagain, ifit still failed, thedefault shouldbethecontrolPCB, replace itwithsamemodel. ( 6.2.2 )

3 >.Theself-checkcanbequit onlydisconnectthepowerplug.

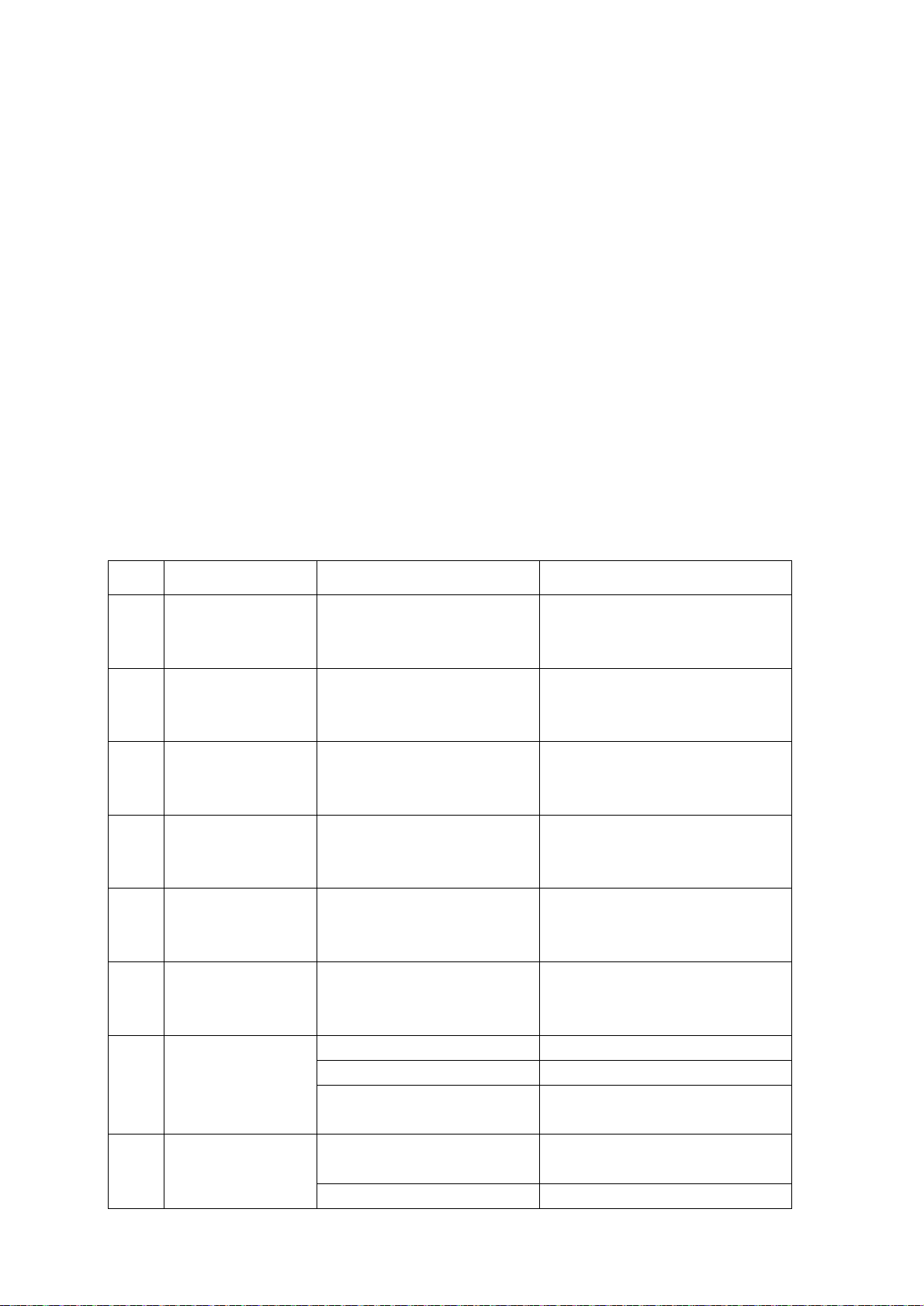

5.2Errcode

Code

Representation Checkingpoint Solution

E1 Uppercompartment

sensoropencircuit

Checkthewiringand connection

betweenPCB andsensor,ifitopen

circuit.

If theconnectionandwiringisnormal,

replacethesensorplease.

E2 Uppercompartment

sensorshort circuit

Checkthewiringand connection

betweenPCBandsensor,ifitshort

circuit.

If theconnectionandwiringisnormal,

replacethesensorplease.

E3 Defrostsensoropen

circuit

Checkthewiringand connection

betweenPCB andsensor,ifitopen

circuit.

If theconnectionandwiringisnormal,

replacethesensorplease.

E4 Defrostsensorshort

circuit

Checkthewiringand connection

betweenPCBandsensor,ifitshort

circuit.

If theconnectionandwiringisnormal,

replacethesensorplease.

E7 Lowercompartment

sensoropencircuit

Checkthewiringand connection

betweenPCB andsensor,ifitopen

circuit.

If theconnectionandwiringisnormal,

replacethesensorplease.

E8 Lowercompartment

sensorshort circuit

Checkthewiringand connection

betweenPCBandsensor,ifitshort

circuit.

If theconnectionandwiringisnormal,

replacethesensorplease.

HI Innertemperaturetoo

high

ACheckifanyrefrigerant leakage. Repairtheleakageandrefill.

BCheckifthecapillaryjam Cleanorreplacethecapillary.

CCheckittheinnerfanrun

normally Repairthewiringorreplacethefan.

LO Innertemperaturetoo

low

aCheckiftheinnerfanrun

normally Repairthewiringorreplacethefan.

bCheckifthePCBnormal. ReplacethePCB.