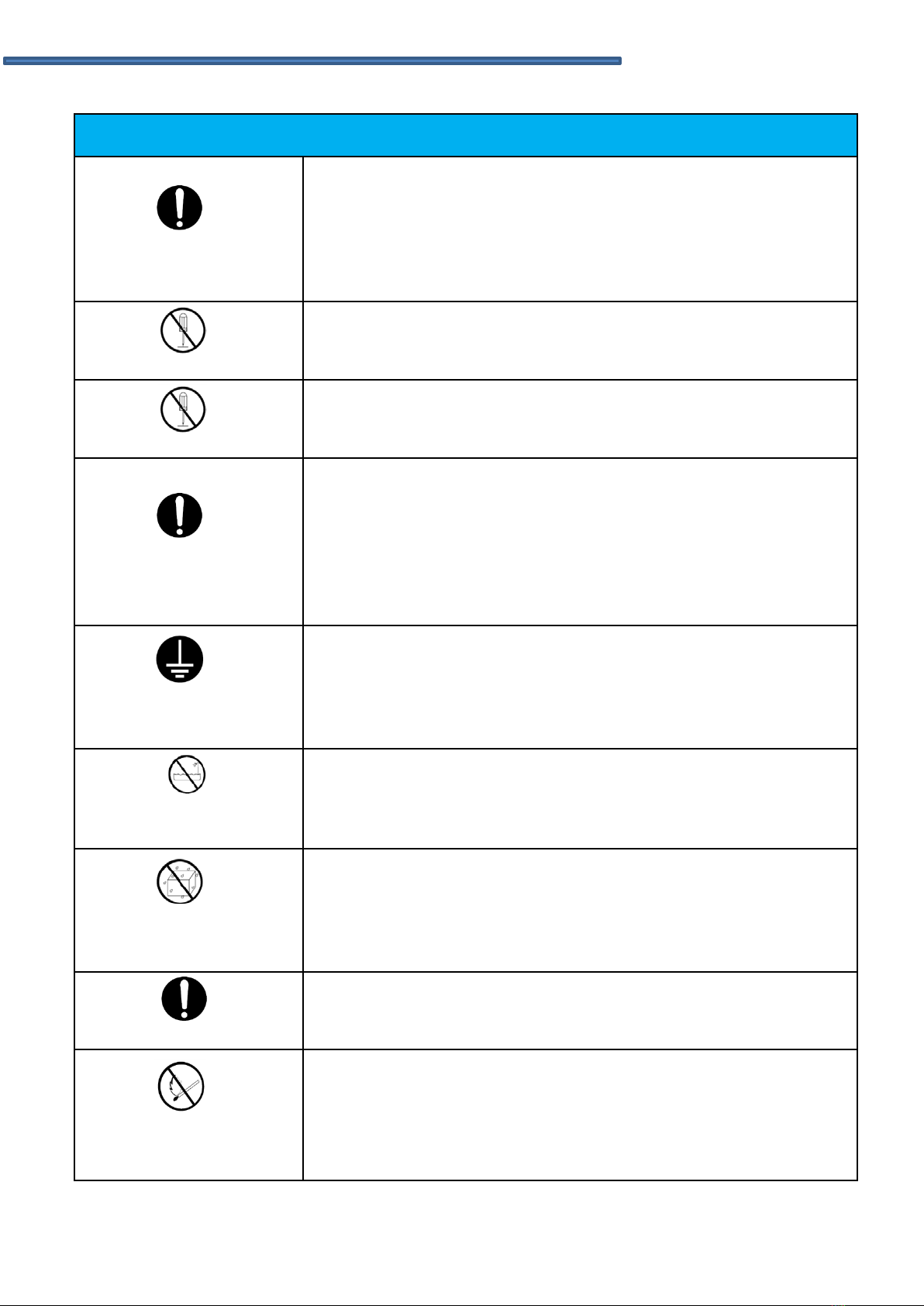

1.3 CAUTIONS FOR SAFETY

•Please observe the following notes for safety.

•The symbols indicate as follows.

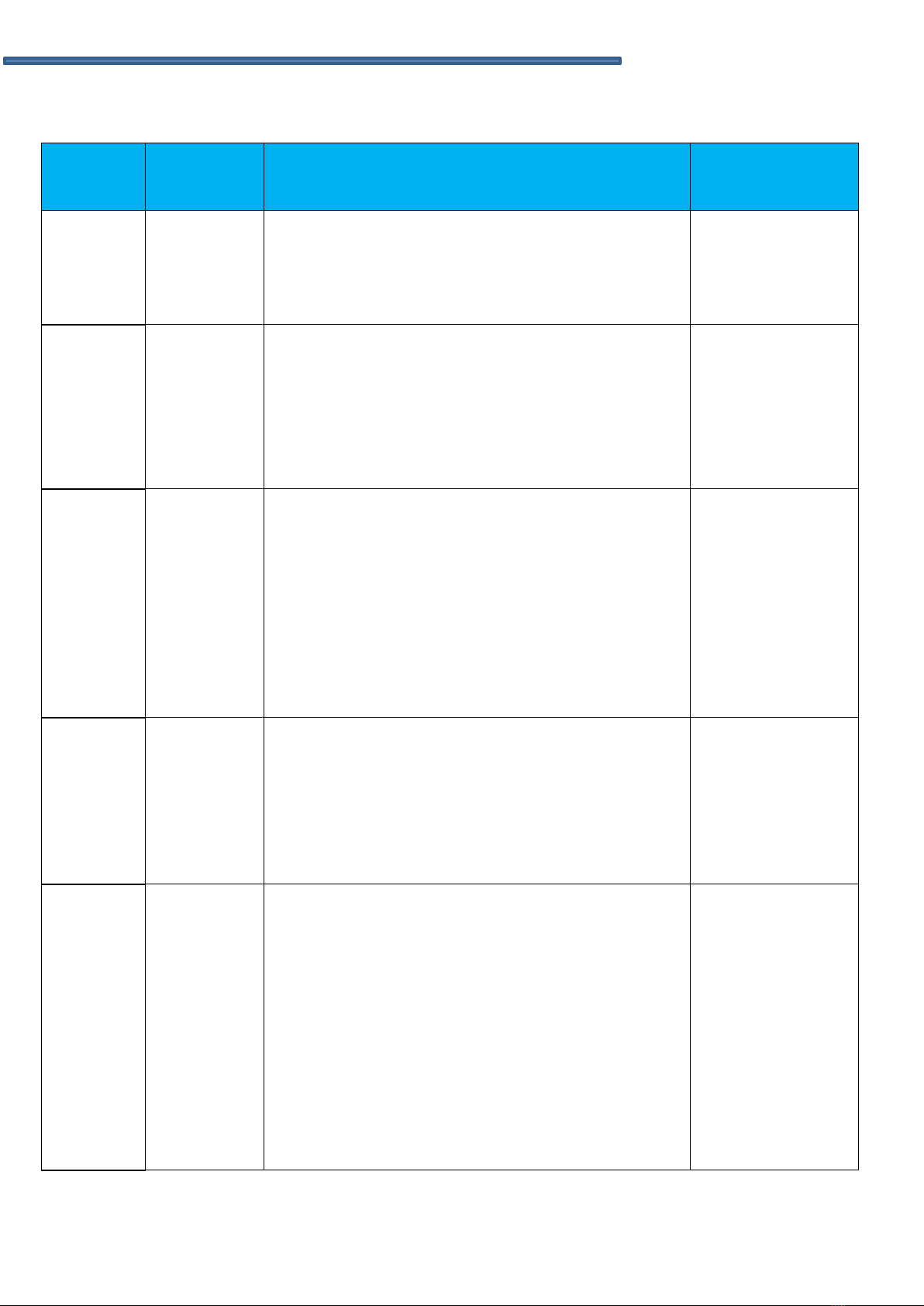

Symbol Meaning

WARNING

Indicates possibility of death or serious injury of a repair

technician and a person nearby through the misconducted

work , or of a user by a defect of the product after the work

performed by the technician.

CAUTION

Indicates possibility of injury or physical damages* of a

repair technician and a person nearby through the

misconducted work , or of a user by a defect of the product

after the work performed by the technician.

Symbol Meaning

ELECTRIC SHOCK

Indicates a caution (including a warning).

Specific instruction is followed by a graphic or characters in

or near.

Symbol left warns an electric shock.

DO NOT DISASSEMBLE

Indicates prohibition (act must not be conducted).

Specific instruction is followed by a graphic or characters in

or near.

DO NOT Symbol left warns not to disassemble.

UNPLUG

Indicates forcing (act must be conducted).

Specific instruction is followed by a graphic or characters in

or near .

Symbol left warns to unplug the power cord.

*Means secondary damages of property, furniture , domestic animal and pet.

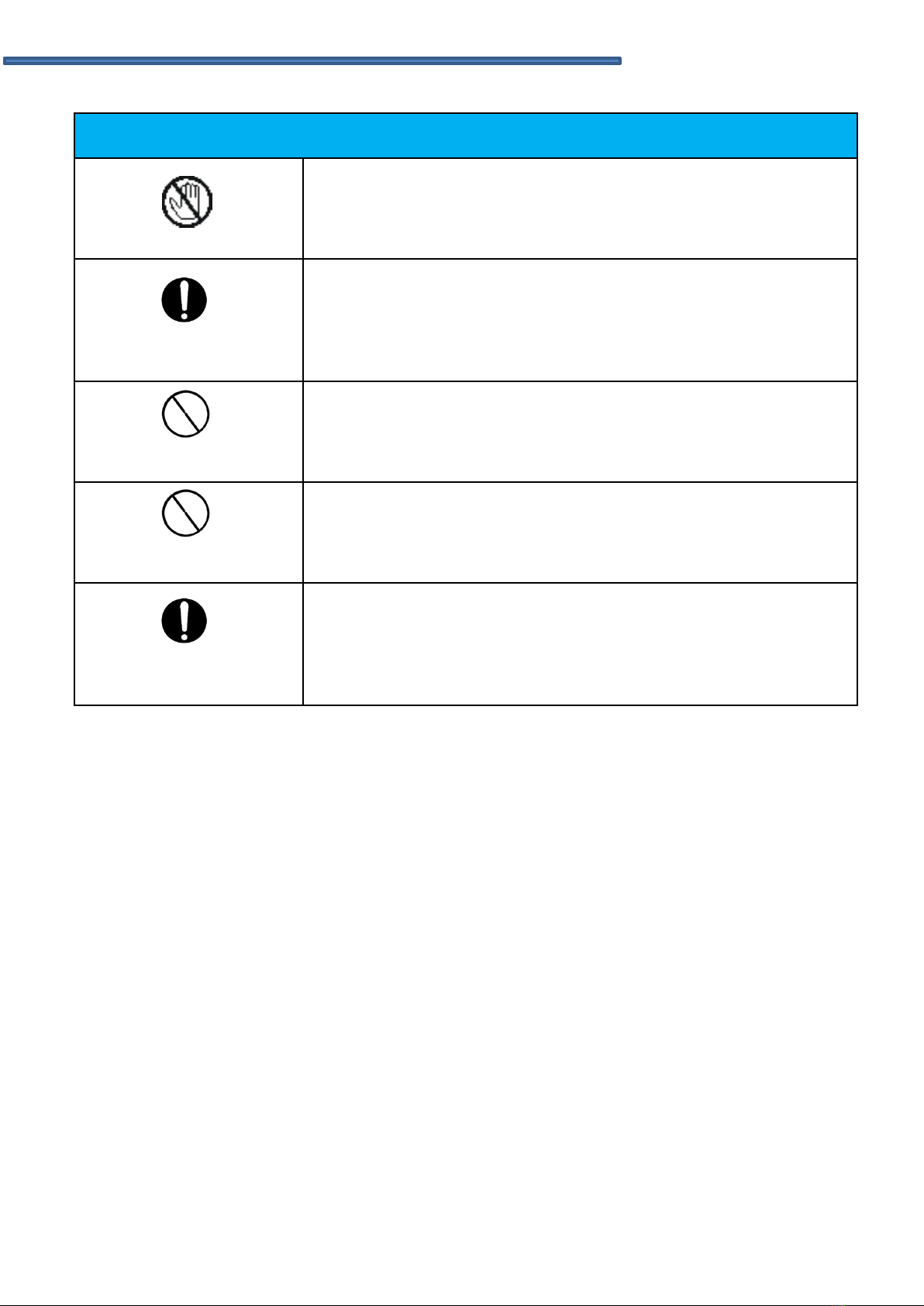

Symbol Meaning

OUT OF CHILD

Advise the customer to keep children out of the work place.

Children may be injured with a tool or a disassembled part.

UNPLUG POWER

Unplug power cord for the work such as disassembling

which is not

unnecessary to power on . Do not hold the plug by a wet hand.

Failing to unplug may cause an electric shock.

USE REPAIR PARTS

Use the specified repair parts when repairing the

product. Otherwise , a malfunction or adefect may occur.

Also , ashort circuit ,ignition or other danger to the

customer may occur.

1 PRECAUTION