M305

305mm

240mm

406mm

1/2HP, 230V/50Hz

6

360, 670, 1020, 1510, 2230, 3250

M33mm x 3.5p

M30mm x 3.5p

MT2

MT2

9.5

60mm

807(L)x457(W)x292(H)mm

48 kgs

Model Number

Swing Over Bed

Swing Over Tool Rest Base

Working Distance Between Centers

Motor

Speeds

Speed Ranges

Spindle Thread (Europe)

Spindel Thread (Australia)

Headstock Taper

Tailstock Taper

Hole Through Spindle

Tailstock spindle travel

Overall Dimensions

Net Weight

Table of Contents

Specifications

1

Table of Contents

Specifications..........................................................................................................................................1

Contents of Package...............................................................................................................................2

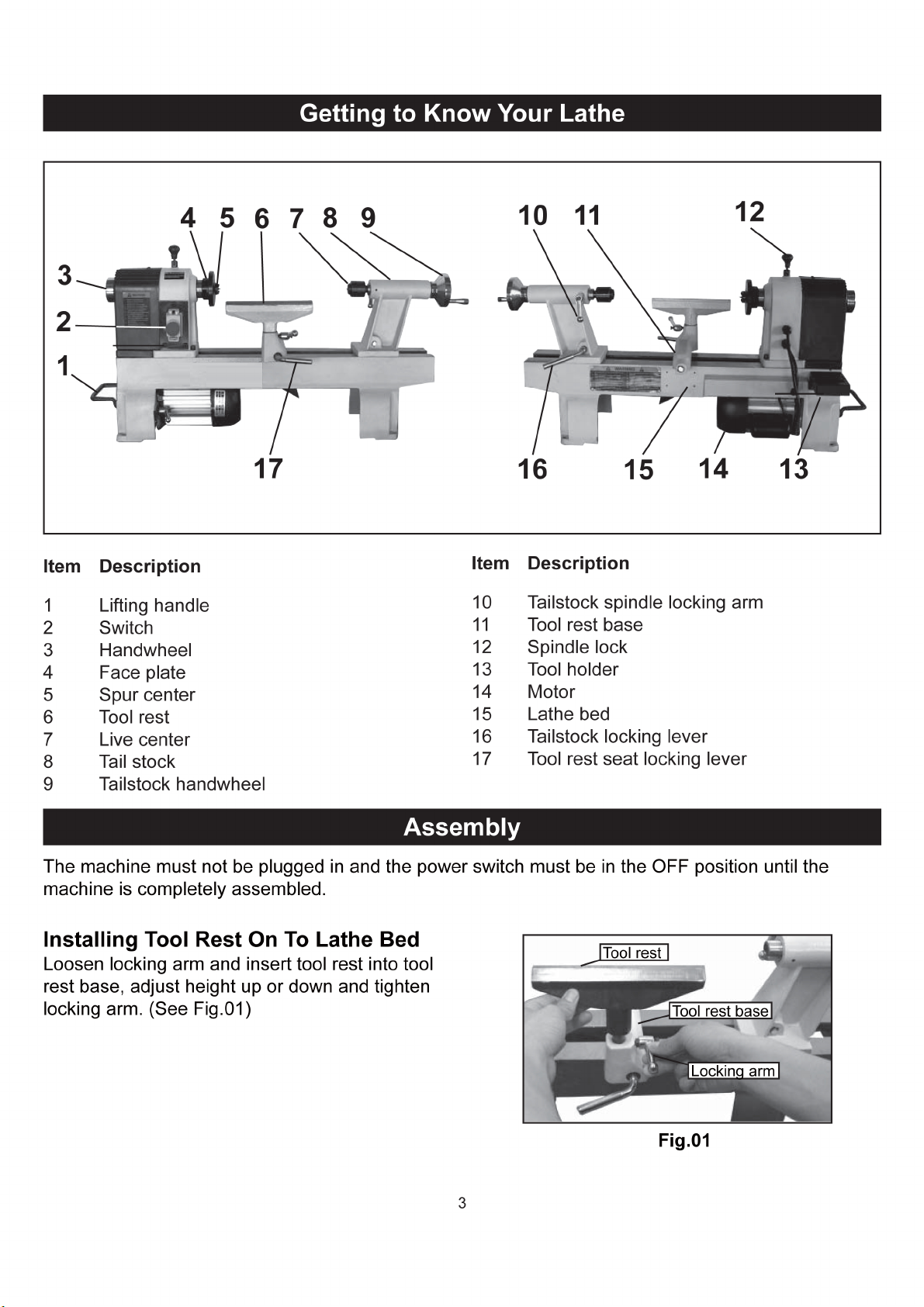

Getting to Know Your Lathe.....................................................................................................................3

Assembly................................................................................................................................................6

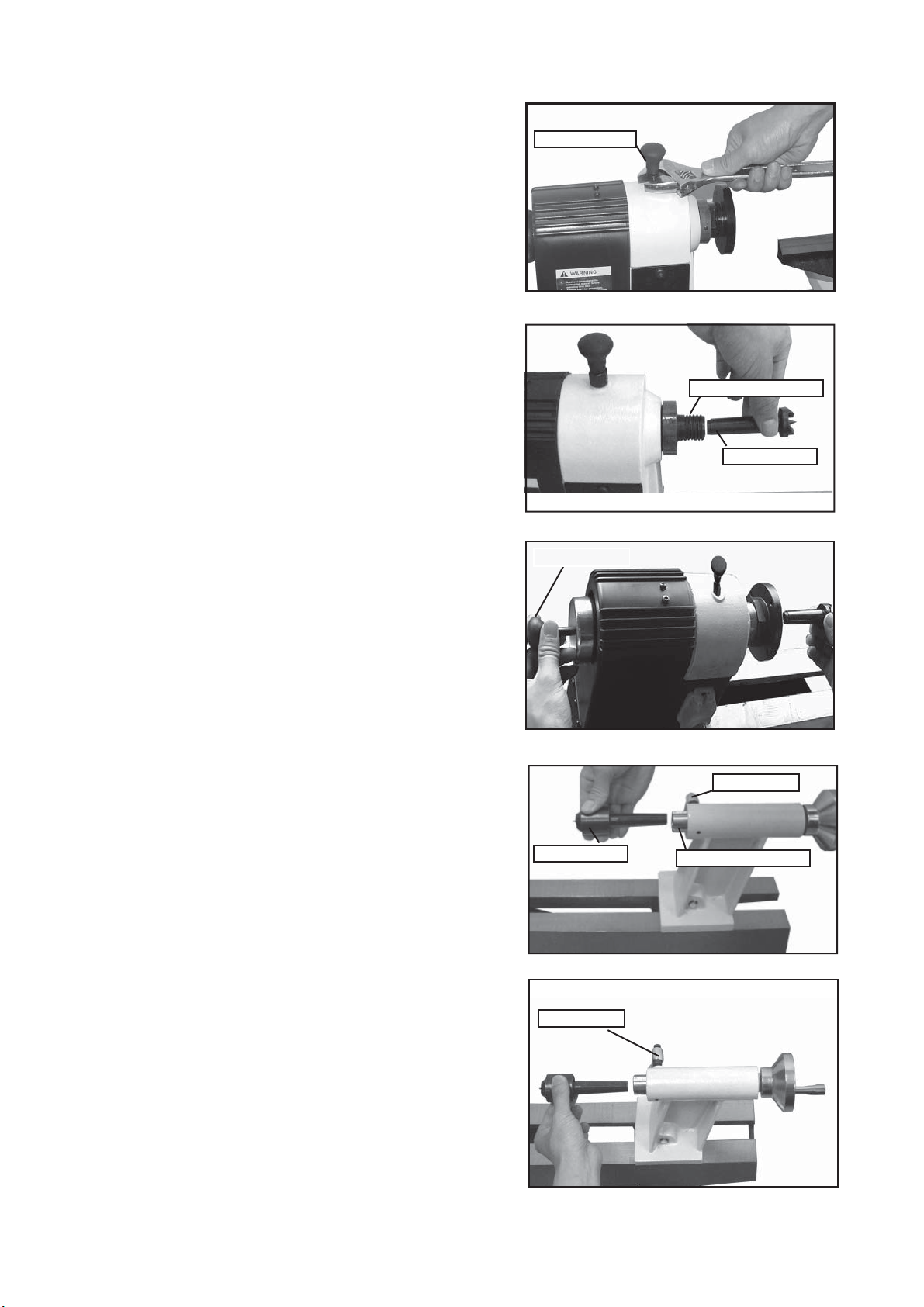

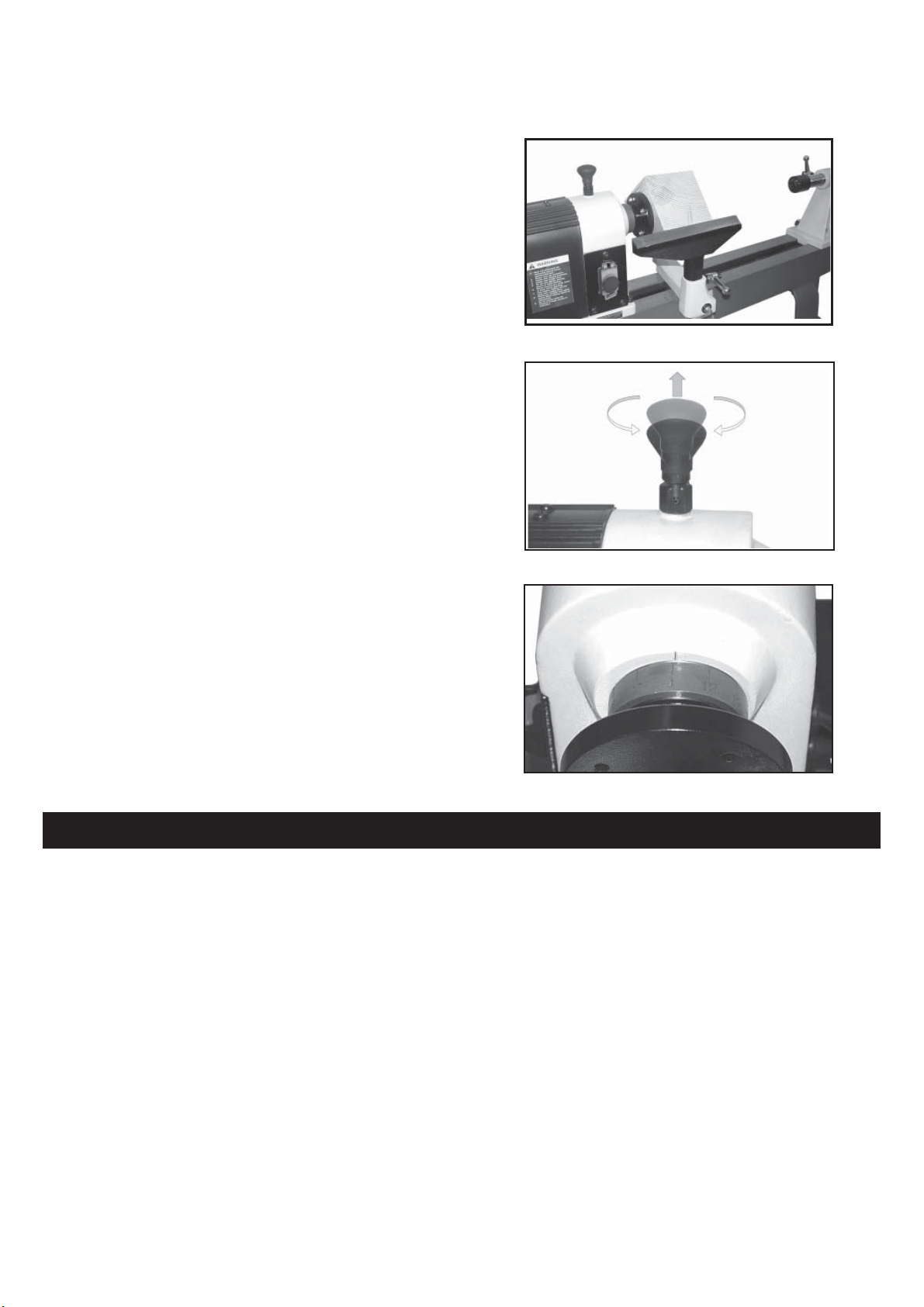

Installing the Tool Rest...........................................................................................................................6

Installing Spindle Lock............................................................................................................................7

Attaching the Spur Center.......................................................................................................................7

Attaching the Live Center........................................................................................................................7

Installing the Faceplate...........................................................................................................................8

Installing the Tool Holder.........................................................................................................................8

Securing the Lathe to a Work surface or Stand........................................................................................8

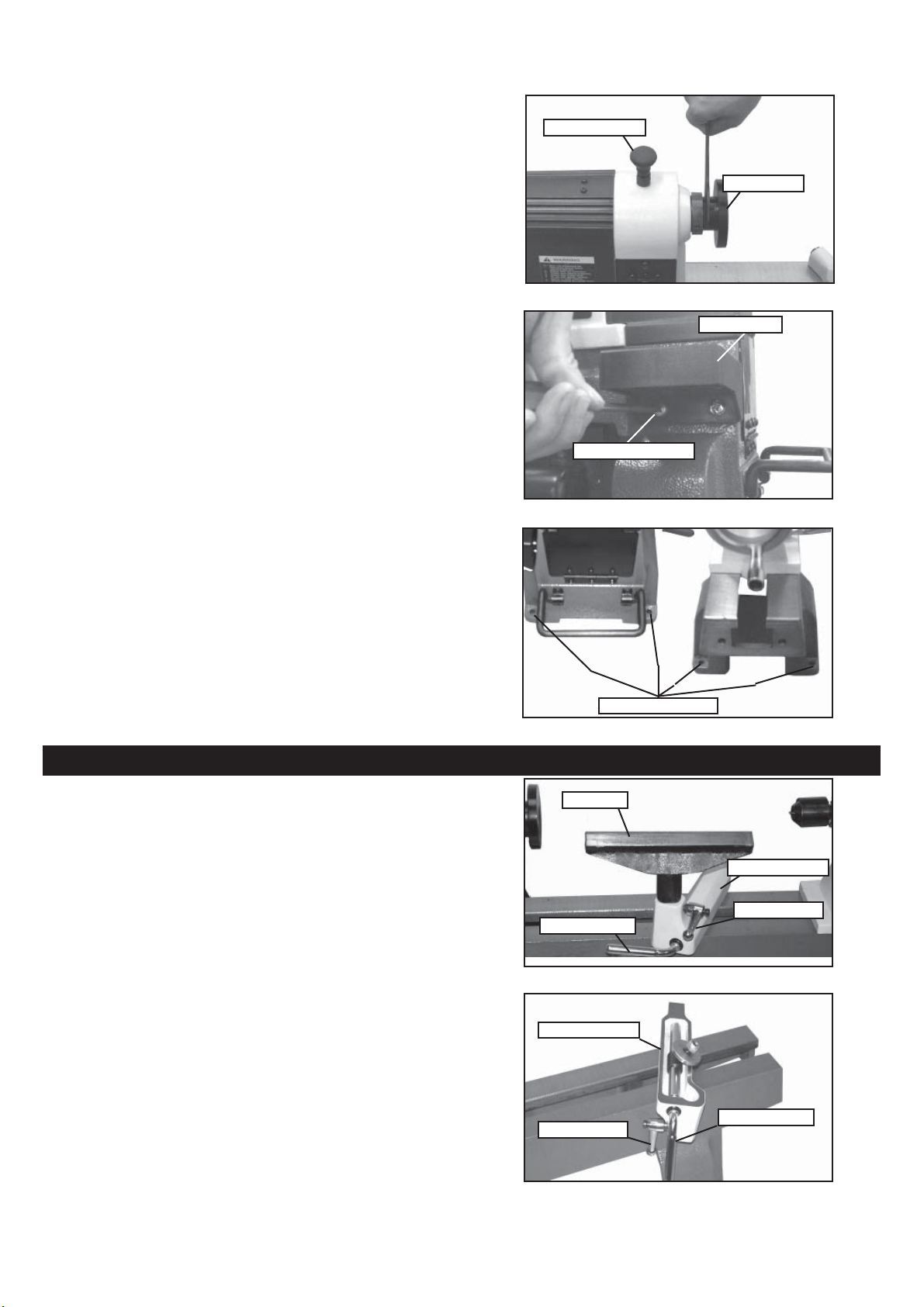

Adjustments............................................................................................................................................8

Adjusting the Tool Rest............................................................................................................................8

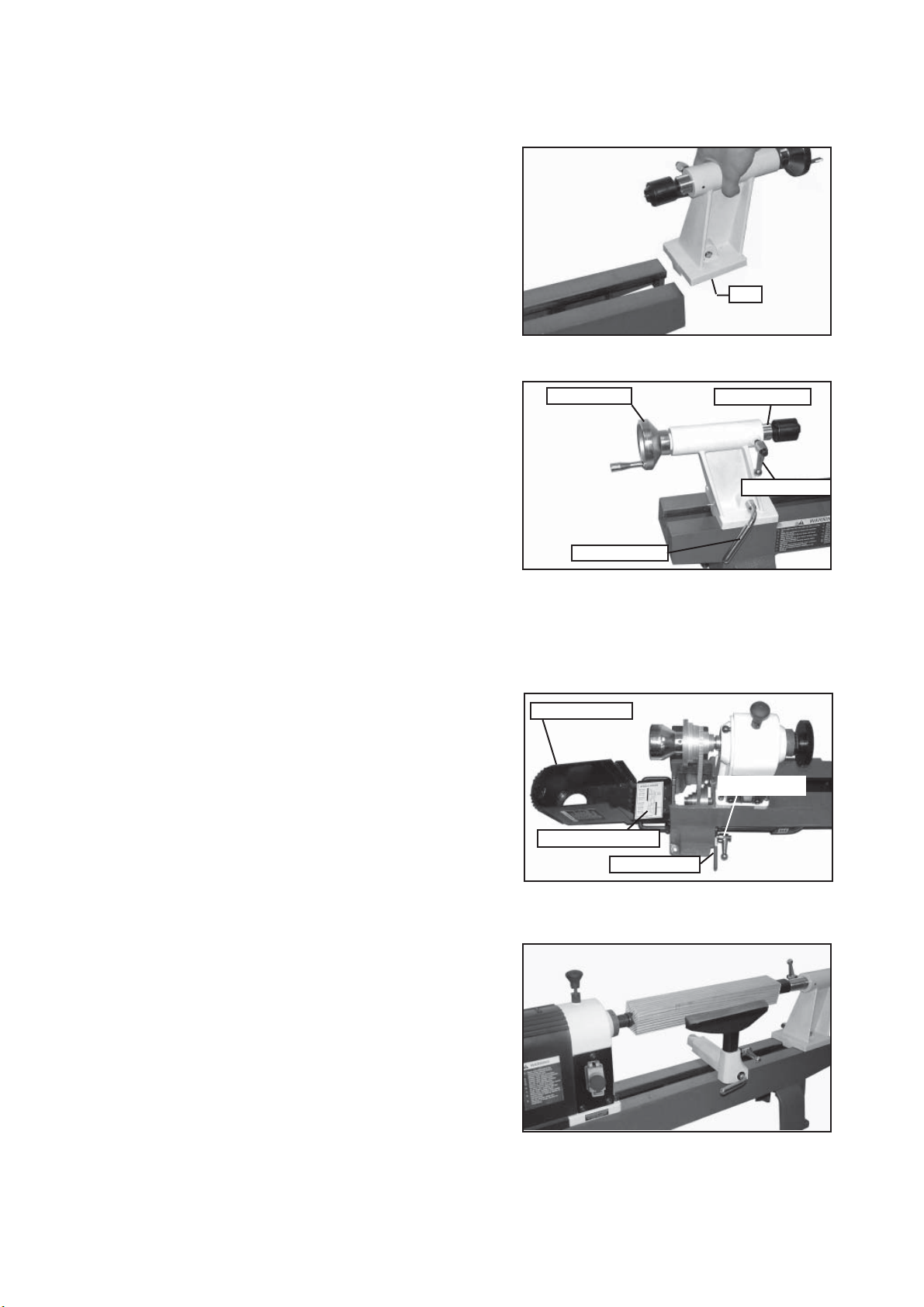

Adjusting the Tailstock.............................................................................................................................9

Changing Spindle Speeds.......................................................................................................................9

Typical Operations..................................................................................................................................9

Indexing /Spindle Lock..........................................................................................................................10

Maintenance.........................................................................................................................................10

Electrical Requirements........................................................................................................................11

Wiring Diagram.....................................................................................................................................12

Troubleshooting....................................................................................................................................13

Explosion Diagram................................................................................................................................14

Parts List...............................................................................................................................................15