200 Controller

MC00 –1.03 3

2BASIC OPERATING INSTRUCTIONS

2.1 Oven Controls

Most Carbolite products are fitted with an “Instrument Switch” which cuts off power to the

controller and other parts of the control circuit. See the instruction manual for the oven for the

overall operating instructions.

To operate the 200 there must be power to the oven, and the Instrument switch must be on. If a

time switch is included in the oven circuit, this must be in an On period.

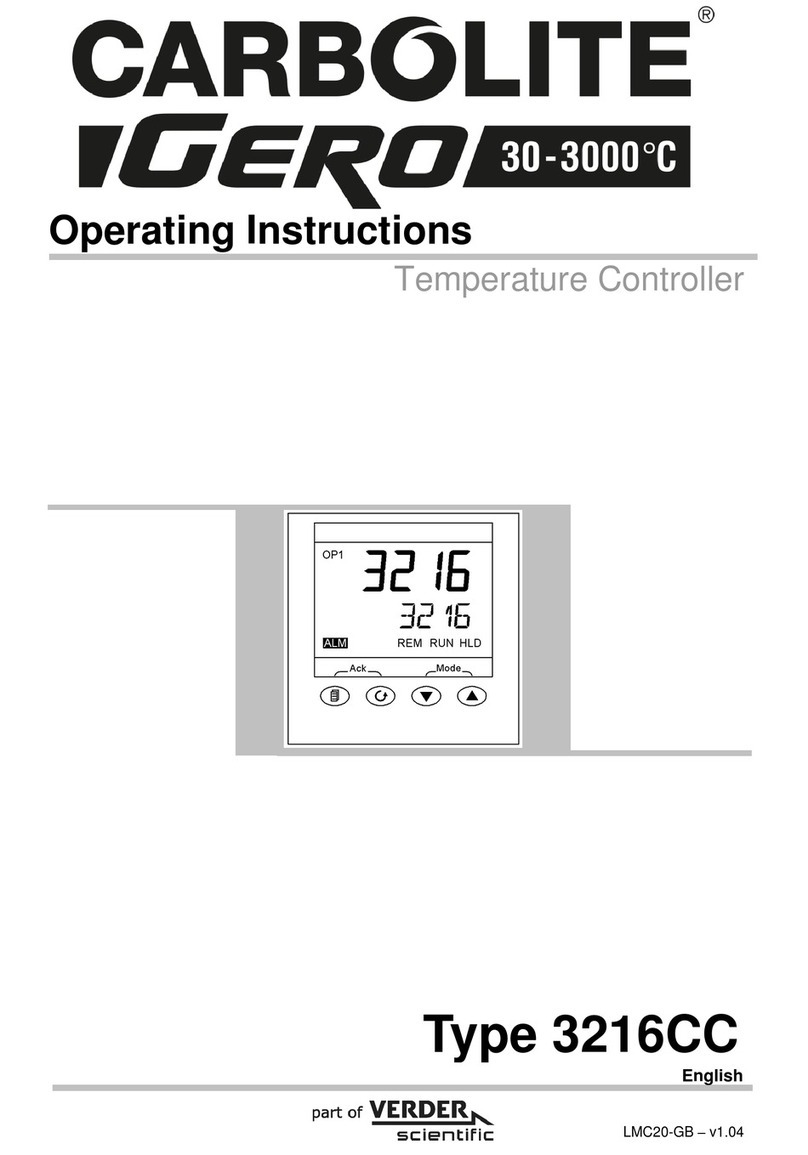

2.2 The 200 –Operation

When switched on, the controller lights up, goes through a short test routine, and then displays

the measured temperature and starts to control. The output light glows or flashes as heating

occurs.

The Page key allows access to parameter lists within the controller; most lists and parameters

are hidden and cannot be accessed by the operator because they contain factory-set parameters

which should not be changed.

A single press of the page key displays the temperature units, normally set to °C; further

presses reveal the lists shown in the Navigation Diagram in section 6.

The Scroll key allows access to the parameters within a list. Some parameters are display-

only; others may be altered by the operator. A single press of the scroll key displays the

temperature units; further presses reveal the parameters indicated in the Navigation Diagram.

To return to the Home list at any time, press Page and Scroll together, or wait for 45

seconds.

The Down and Up keys are used to alter the setpoint or other parameter values.

2.3 Basic Operation

Normally no operator action is required other than entering the setpoint, as the 200 starts to

control on being switched on, as described above.

2.4 Altering the Setpoint

With the display at “home”, showing the measured temperature, press Down or Up once to

display the setpoint; press again or hold down to adjust it. The display returns to the measured

temperature when no key is pressed for 0.5 seconds.