201 Controller

OVERTEMPERATURE OPTION

This is only fitted when the overtemperature option is ordered. To identify whether it is fitted,

observe the controller panel: if it is fitted the overtemperature key and warning light are present.

The overtemperature key must be held depressed continuously while viewing or adjusting the

overtemperature controller. If the Overtemperature key is released, the display reverts to the

main controller.

With the key pressed the overtemperature setpoint is normally displayed. To alter the value, use

Down and Up. To view the measured temperature, press Scroll until PV (process variable) is

displayed, then press Down or Up. Keep the overtemperature key depressed during these

operations.

When an overtemperature condition is reached, the overtemperature warning light changes from

green to flashing red. To “accept” or “reset” this alarm condition, press the Overtemperature key

and the Page key together; the warning light changes to continuous red. Once the over-

temperature condition is cleared (by the temperature falling), the light changes to green and

normal operation resumes.

4 ALTERING THE POWER LIMIT

4.1 Overview

Depending on the furnace or oven model the power limit parameter OP.Hi (Output High) may be

accessible or hidden.

For silicon carbide heated furnaces the parameter is accessible to allow for compensation for

element ageing (see the appropriate section in the furnace manual). In wire-heated chamber or

tube furnaces, reducing the power limit is a convenient method of improving control at low

temperatures, as outlined below.

The power limit may be set to zero to permit demonstration of the controls without heating.

In many models the power limit setting depends on the supply voltage; usually the furnace or

oven manual contains details: if in doubt, contact Carbolite for advice.

The power limit parameter does not apply to the overtemperature controller, if present.

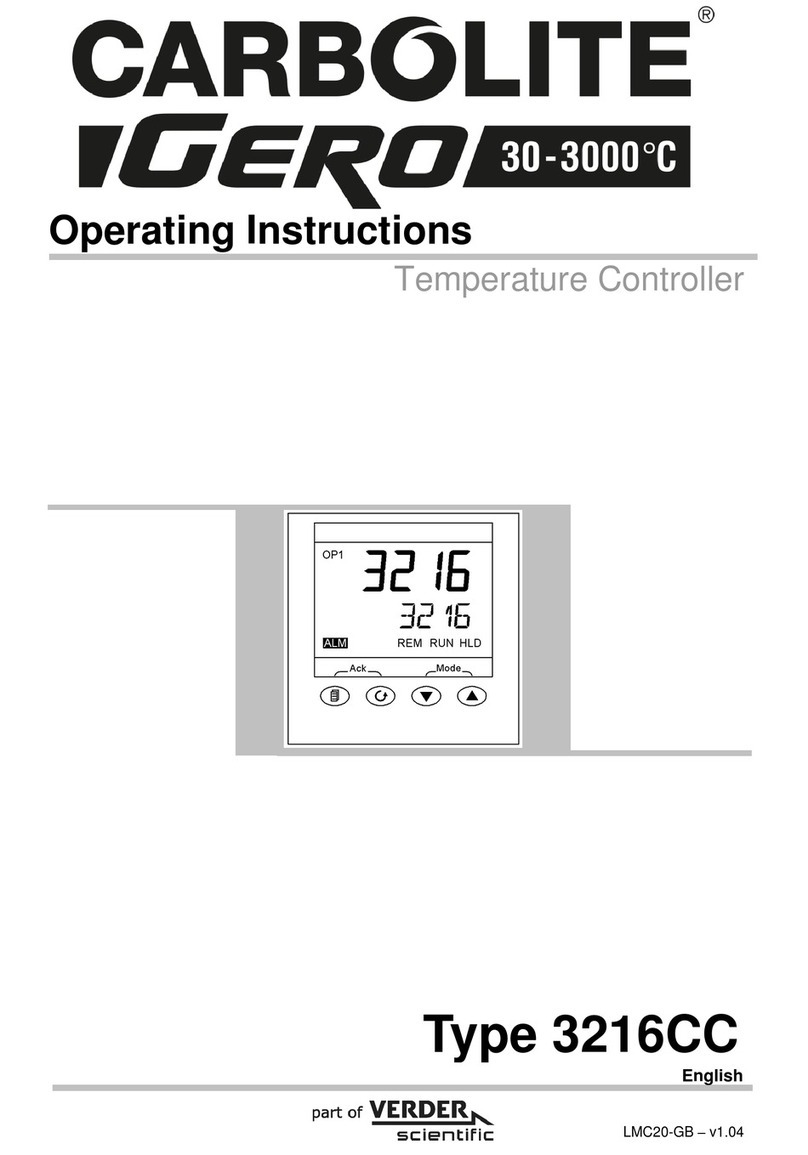

4.2 Altering the value

Press Page until oP (output list) is displayed. Press Scroll 4until OP.Hi (Output High) is

displayed. Press Down Tor Up Sonce to display the value of OP.Hi and write down the value.

To alter the value, use Down Tor Up S. Note that setting the value to zero prevents the furnace

or oven from heating.

Caution: Do not increase the power limit value to a value above the design level for the oven or

furnace model, or to a value above that correctly calculated for Silicon Carbide elements. The

heating elements could burn out, or other damage could be caused.

4.3 Control at Low Temperatures

If a product is to be used at temperatures much lower than its design maximum, control stability

can often be improved by reducing the power limit. Remember to make a record of the original

setting before altering the power limit.

Example: It is desired to run a 1200°C furnace at 300°C. The normal control settings can be

expected to cause excessive overshoot as the furnace reaches temperature. If the power limit

OP.Hi is normally set to 100%, try a setting of 40%. This should greatly reduce the overshoot.

(There is no firm calculation rule to get this example setting of 40% – experiment may be

required to achieve a good result. Avoid power limits below about 30% – control accuracy falls

off at such levels.)

5

MC07 5