Quick Start Guide

6 MC18-GB – v1.04

3 Quick Start Guide

3.1 Operation as a simple controller

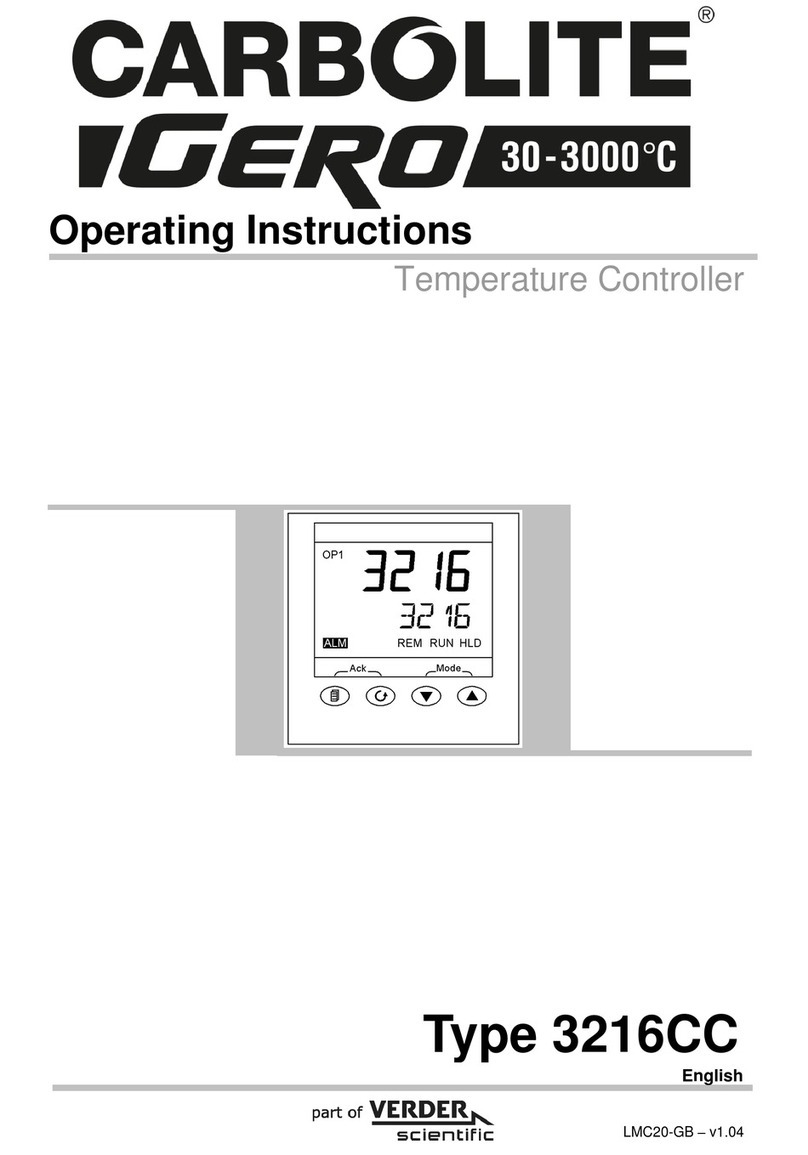

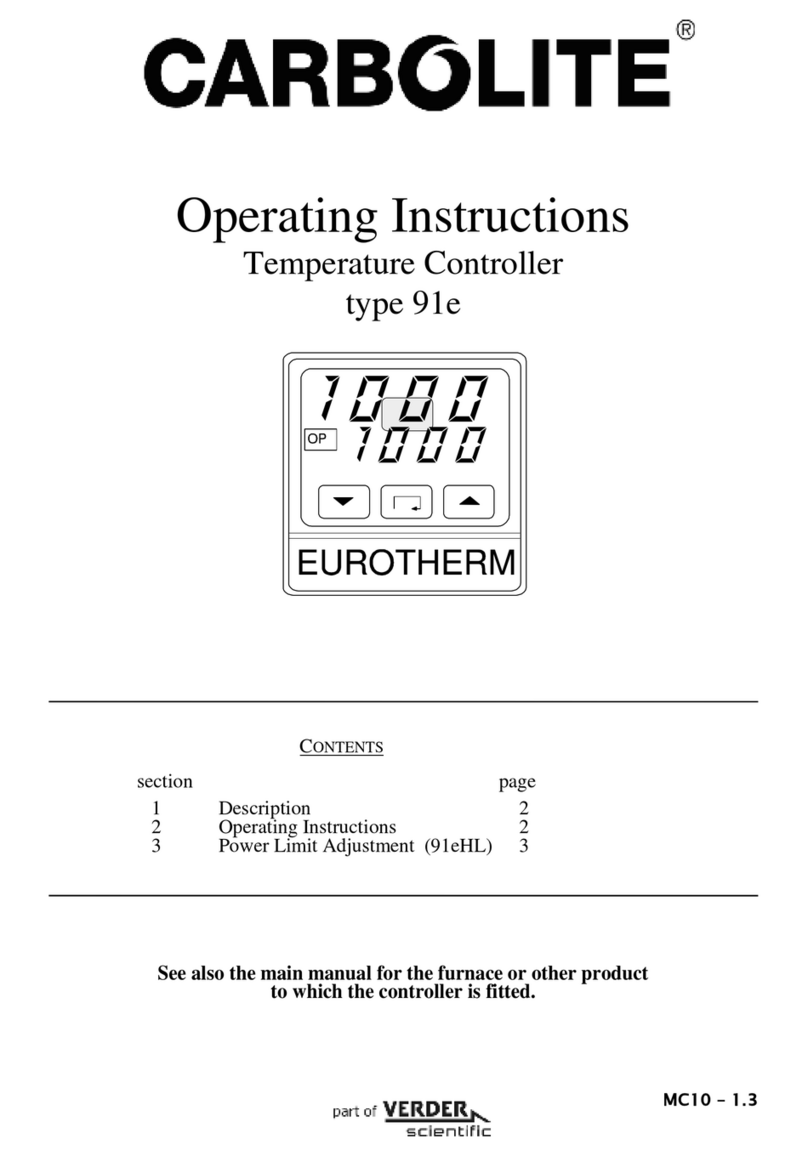

When switched on, the controller goes through a short test routine and then shows the

measured temperature (PV = Process Value) in the upper part of the display, and below it,

the set temperature (Set Point).

3.2 Changing the Set Point

Press Up Sor Down Tto select the required SP. If the SP is higher than the measured

temperature, the OP1 indicator will illuminate in the top left corner of the display, indicating

that the controller is calling for power (giving an output).

The controller will immediately attempt to reach the set temperature and then maintain it.

3.3 Using The controller

The parameters in the controller are first shown by a short code (mnemonic). After 5

Seconds a description of the parameter will scroll once along the display and then revert

back to the mnemonic. The scrolling text can be interrupted at any time by a single press of

any of the buttons, but will not scroll again until the parameter is returned to. In this manual

the mnemonic will be shown first, followed by the scrolling text in brackets;

e.g. Prog <program number>

3.4 Understanding User Levels

There are two user levels in the controller; Level 1(Operator) and Level 2 (Supervisor).

Level 1 (Operator) is for the day to day operation of the controller. These parameters are

not protected by a security code.

Level 2 (Supervisor) provides access to additional parameters. Access to these is protected

by a security code

To Enter Level 2

1. Press and hold the page key for 3 seconds.

2. The display will show Leu 1 GOTO

3. Release the page Key

4. Press the UpSor Down Tto choose LEu 2 (level 2)

5. Press the Up Sor Down Tto enter the code (Level 2 Code = 9).

If the correct code is entered, PASS should momentarily be displayed and then revert to the

level 2 home display (See Section 5.3)

If an incorrect code is entered the display reverts back to Level 1 home display (See Section

5.3)