10/2010 - Art. Nr. 4200 1032 1300A 13

Commissioning

Working cycle test

Firing

Safety unit settings and checks

e

- Pre-ventilation,

- Return to ignition position,

- Ignition of electrodes,

- Valves open,

- Burner stops due to lack of gas

pressure or control unit locks because

flame is extinguished.

- If unsure, redo the above test.

The unit can only be fired once this very

important operating sequence check

has been performed.

Firing

Warning:

The burner may be only fired when

all the requirements listed in

previous sections have been met.

• Connect a microammeter (scale 0 -

100 µA DC).

• Open the quarter-turn hand-operated

fuel valve.

• Close the thermostatic circuit.

The leak tester is charged. After running

the test (30 s), the control unit

programme will relaunch. After pre-

ventilation, the burner comes on and

operates at minimum power.

• Check the following:

- the combustion

- the overall leak tightness of the gas

train using foam designed for this

purpose.

No leaks should be detected.

• Measure the gas flow shown on the

counter.

• Slowly increase the power to nominal

output, controlling the combustion

throughout. If necessary, adjust the

combustion by adjusting the

Pair:Pgas pressure ratio ( ,

Screw R).

• Adjust the servomotor control cam I

(Nominal output) to limit the maximum

opening of the air flap to the position

reached for nominal output.

• Slowly reduce the power to the

nominal output required, checking the

combustion values throughout; if

necessary, at minimum power, adjust

the combustion via parallel shifting of

the characteristic ( , Screw D).

• Adjust servomotor control cam III

(Minimum output) to limit the minimum

opening of the air flap possible during

operation to the position reached for

minimum output.

•Precautions: On principle, the

nominal output must only be modified

by adjusting the Pair:Pgas pressure

ratio ( , Screw R), and the

minimum output must only be

modified by offsetting in parallel to the

characteristic e ( , Screw D).

• After any modification to the minimum

output settings, check the combustion

at nominal output and adjust if

necessary.

• After any modification to the nominal

output settings, check the combustion

at minimum output and adjust if

necessary.

• To complete the adjustment process,

restart the burner and check the

power and the combustion. If

necessary carry out adjustments as

described above.

• Check the leaktightness of the gas

train.

• No leakage should be detected.

• Check the safety devices.

• Setting and checking the safety

devices

Gas pressure switch

• Set it to the minimum distribution

pressure.

• The burner operates at minimum

output.

• Slowly close the 90° manual shut-off

valve.

• The burner must stop due to a lack of

gas pressure.

• Open the 90° manual shut-off valve.

• The burner restarts automatically.

• The pressure switch is set.

• Fix and screw on the cover.

Air pressure switch

• See the paragraph entitled

"Determining the differential pre-

ventilation pressure and setting the

differential pressure switch" (page

16).

Leak testing device VPS:

• Open pa on the device.

• Restart the burner. After 30s the tester

should enter safety mode (red light

on).

• Reclose pa.

• o Unlock the tester safety catch by

pressing the red indicator.

The test cycle is relaunched.

The burner will be working.

• Check the leaktightness.

• Disconnect the measurement devices.

• Re-close the pressure tap.

• Reset the unit.

The burner will be working.

• Check:

- the seal between the flange and the

boiler front,

- the opening of the control circuit

(limiter and safety),

- the current on the motor relay.

• Check the combustion under actual

working conditions (doors closed,

cover in place, etc.) and check all

circuits for possible leaks.

• Establish a measurement protocol.

• Start-up automatic operation.

• Provide all the data required for proper

operation. (Inform the boiler room

operator).

• Place the boiler plate in a visible

location.

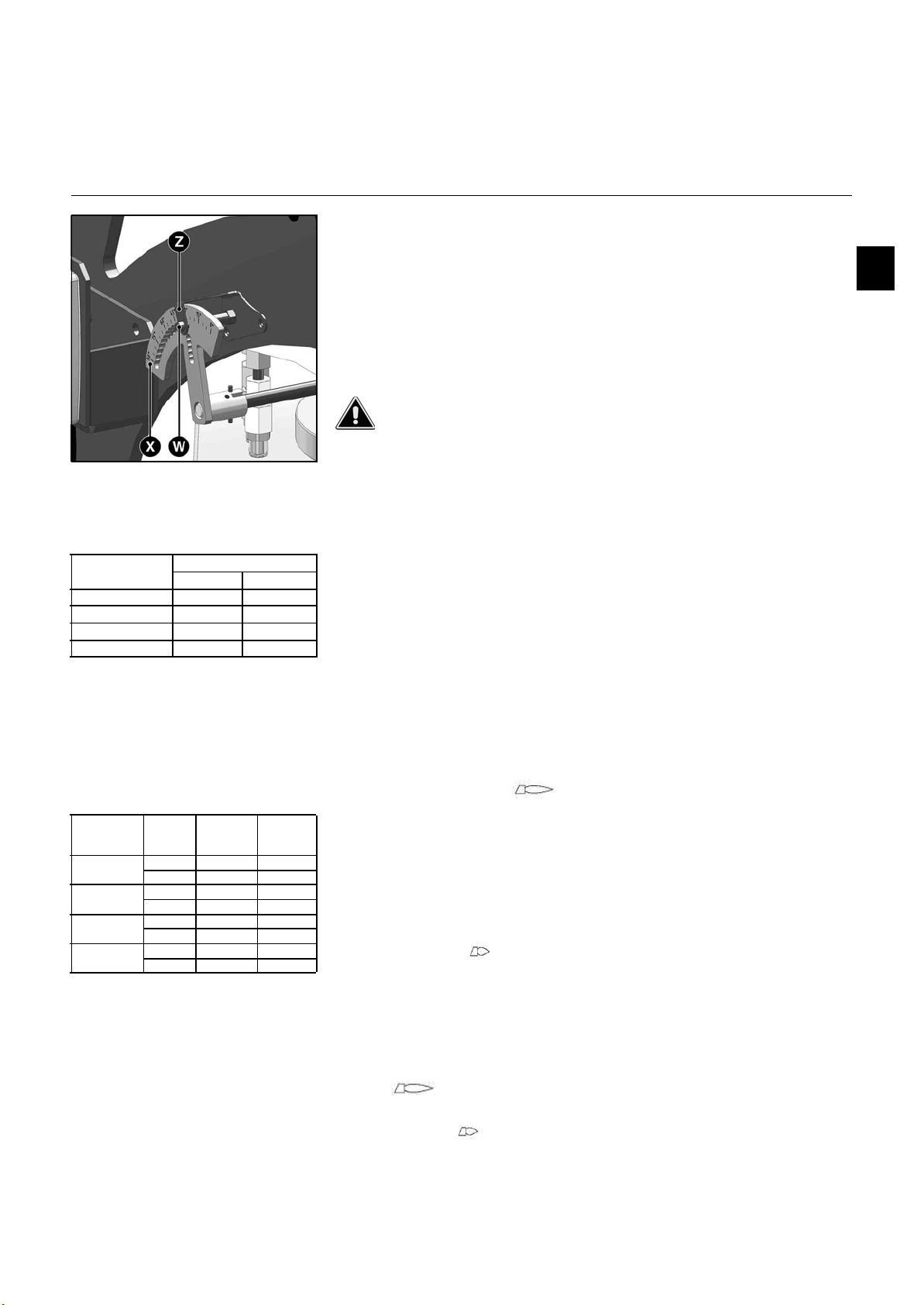

Important!

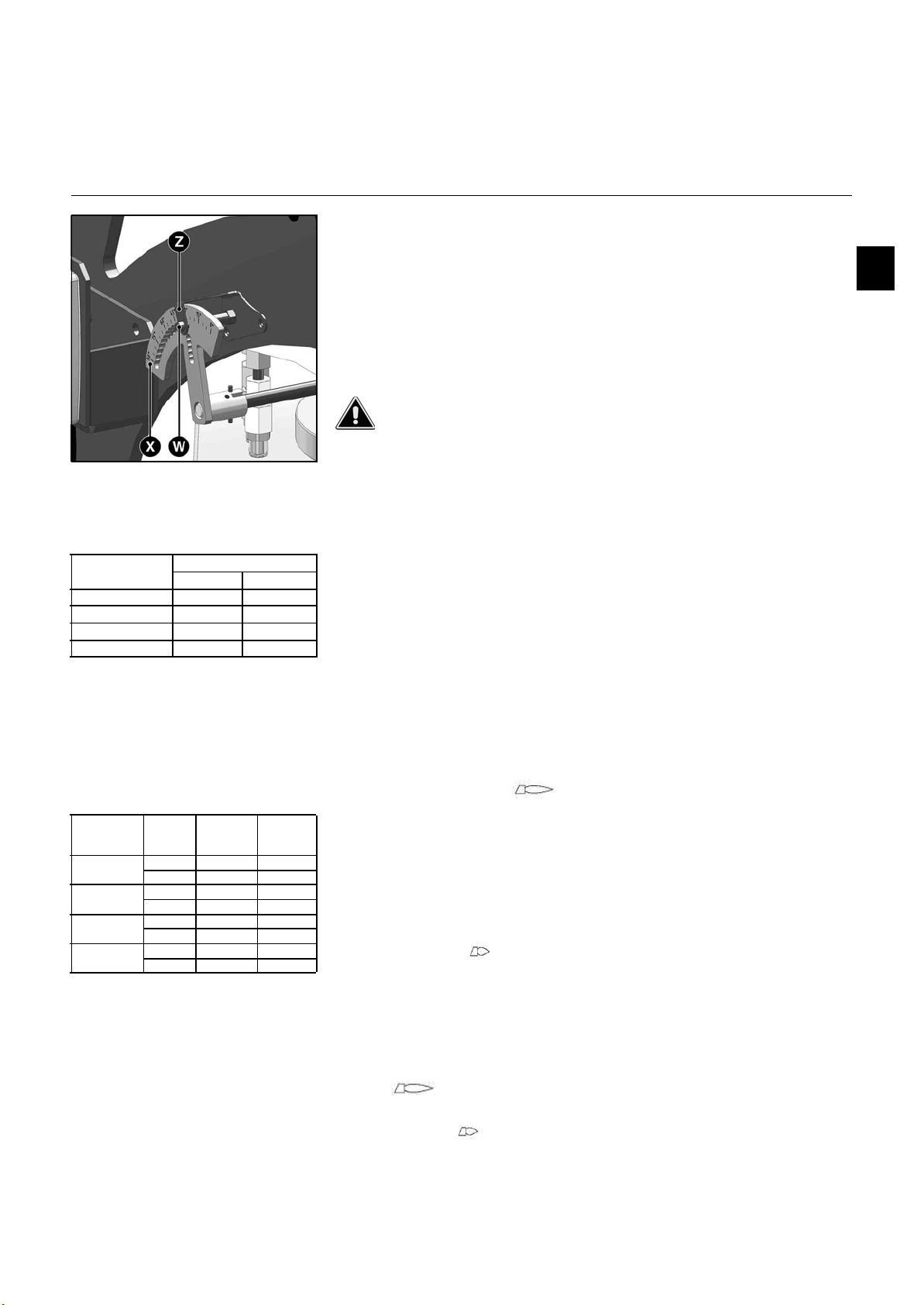

Before firing, to ensure the gas train

operates correctly, the position of the

gas flap must be checked. The table

below shows the recommended setting

depending on the burner.

• If a correction is necessary, proceed

as follows:

• Loosen screw S.

• Manually move lever Hto the

recommended position (setting

according to the table above).

• Lock into position using screw S on the

housing mounting bracket.

Pre-setting the SKP 75 according to

the table below: (these values are

given as a guide only)

Pre-setting the pressure switches on

the burner and the gas train

See the "Commissioning, Gas pressure

switch/air pressure switch" section.

Checking the operating sequence

• Open the quarter-turn hand-operated

fuel valve, then immediately close it

again.

• Switch the burner on.

• Select manual operation mode on the

control cabinet.

• Close the thermostatic circuit.

The VPS 504 S02 leak tightness test

device is switched on. After 30 s if the

test is validated, the amber light will

come on. The control unit is now

powered on.

The program should function in the

following way:

- Air flap opens to the servomotor

nominal output position,

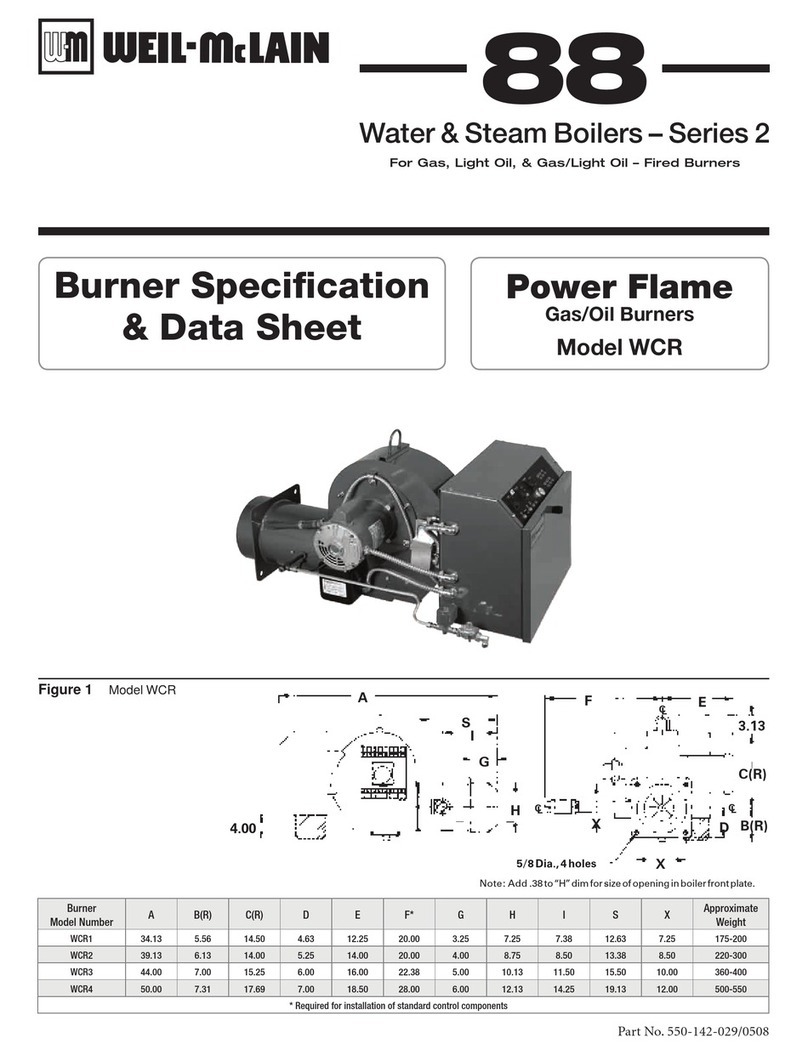

Burner Setting (°)

50 mbar 300 mbar

N6.2400 G-V 90 45

N6.2900 G-V 90 45

N7.3600 G-V 45 45

N7.4500 G-V 45 45

Burner Gas

pressure

[mbar]

Shift from

origin

(screw D)

Pressure

ratio

(screw R)

N6.2400 G-V 50 0,5...0,9 0,8

300 2,9...4,0 2,2...2,3

N6.2900 G-V 50 0,9 1,3...1,4

300 2,9...3,7 2,2...2,3

N7.3600 G-V 50

300

N7.4500 G-V 50

300