8

MN60200FR1 070319© Copyright 2019 — Carlin Combustion Technology, Inc.

TECH SUPPORT HOTLINE 800-989-2275

Carlin Combustion Technology, Inc.

126 Bailey Road North Haven, CT 06473 Phone 203–680–9401 Fax 203–764–1714

FROZEN PIPES/WATER DAMAGE

This is not a freeze protection device. Suitable freeze protection monitoring or other precautions are recommended to protect against

ruptured pipes/water damage caused by fuel outage, safety related fault conditions or equipment failure.

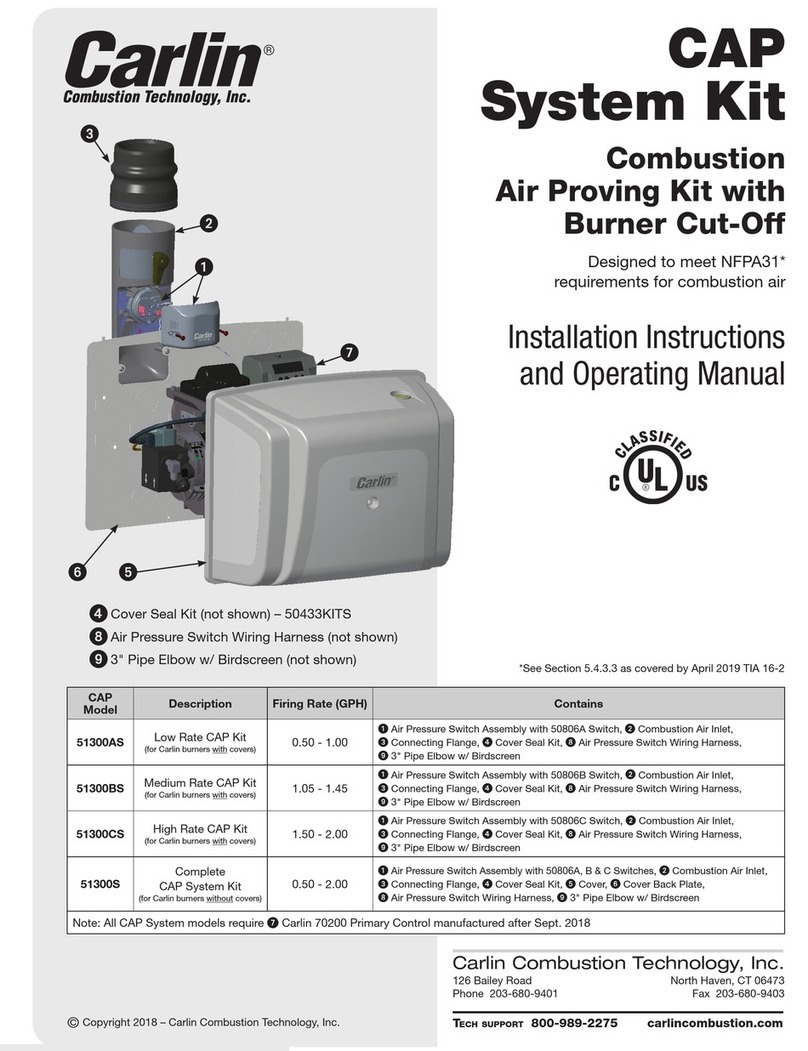

Service and Troubleshooting

Last Fault Display: When the control is reset from a lockout

condition, if the burner resumes normal operation, the screen

will toggle the last fault and its cause for five days (longer du-

ration if control is not wired for constant power). This feature

is designed to allow the service technician to easily see what

caused the condition in the event the homeowner reset the

control prior to their arrival. The screen will alternate between

displaying what the last fault was and displaying how to clear

the message hold ESC for 3 seconds.

Display Voltage and Current: Press + for 3 seconds to

display real time voltage and current.

Lockout: If lockout occurs, the screen turns on, the fault icon

flashes and a fault message is displayed on the screen. To

Reset Push in and hold the red Reset button for 1 second,

then release. NOTE: Recycling power to the control will not

reset it from it from a lockout condition.

Two fault conditions result in an immediate lockout. These

include; Flame detected during pre-purge and flame failure

during Trial for Ignition. All other faults will result in a Recycle

(unless the Allowed Recycles is set to ‘None’ in the Set-up

Menu). A Recycle results in the burner shutting down for 60

seconds then resuming operation in Standby (if there is no

Call for Heat) or initiating the Operating Sequence above (if

there is a Call for Heat).

Latch-up: If the control locks out 3 times during a single Call

for Heat, Latch-Up will be displayed on screen.

To Reset the control after latch-up, press and hold the red

Reset button for 30 seconds. WARNING: Only a qualified

service technician should attempt to reset the control

after latch-up. The problem that caused the repeat lock-

outs must be corrected before returning the burner to

normal operation. NOTE: Recycling power to the control will

not reset it from it from a latch-up condition.

Burner will not fire

• Check line voltage to the control (at least 102 vac).

• Check all electrical connections.

Other no start problems:

• Valve lead voltage on too early. Correct bad connection.

• Motor relay welded. If valve has no voltage, and line voltage

is okay (102 - 132 VAC), the issue is a welded motor relay.

Replace the control.

• Motor current less than 0.2 Amps.

Blocked vent – not recycling:

• Recycle only works on non-manual reset vent switch

Repeated flame failures

Check for:

• Excessive airflow or draft causing flame to leave burner

head- check for proper air band setting and draft.

• Excessive back pressure causing flame to be erratic –

check appliance and flue for sooting/plugging.

• “Flame rod shorted” message in lockout – defective flame

rod assembly.

Control locks out at end of TFI

• No fuel to burner – check fuel supply lines.

• Shorted electrodes – inspect for cracked porcelain and

replace as needed.

• Airflow too high – check air band setting.

• Ignitor module defective – replace if no spark.

• Check wiring connections.

• Flame rod shorted to ground or defective.

Amps = 7 uA

Line = 115 VAC

Toggle

Last Fault

No Flame Chk Ign

To Clear Message

Hold 3 Sec