TTC2000

3703E NOV 07

Box 116

428 22 KÅLLERED SWEDEN

Tel +46 (0)31 720 02 00 Fax +46 (0)31 720 02 50

INSTRUCTIONS INSTRUCTIONS

Control principle

TTC2000 pulses the full load On - Off. TTC2000 adjusts the mean power

output to the prevailing power demand by proportionally adjusting the ratio

between On-time and Off-time. The cycle time (=the sum of On-time and

Off-time) is adjustable 6 - 120 seconds.

TTC2000 has zero phase-angle firing to eliminate RFI.

TTC2000 automatically adapts its control mode to suit the dynamics of the

control object .

For rapid temperature changes i. e. supply air control TTC2000 will act as a

PI controller with a proportional band of 20K and a reset time of 6 minutes.

For slow temperature changes i. e. room control TTC2000 will act as a P

controller with a proportional band of 1.5K.

External control signal

TTC2000 can also be run against an external 0 - 10V DC control signal.

Remove the wire strap between terminals 7 and 9 and connect the control

signal as shown in figure 9.

0V input signal will give 0% output and 10V input will give 100% output.

Minimum and maximum limit functions are not active when using an external

control signal.

NOTE: Do not leave the input unconnected since an open circuit will not

give 0% output but approx. 50%.

To ensure 0% output when no control signal is connected the control input

should be short-circuited.

TT-S1

The power handling capacity of the TTC2000 can be increased by using

the TT-S1 relay control board. On increasing heat demand theTTC2000 will

primarily activate the triac controlled output. When this is running at full

output the TT-S1 relay output will be activated and the triac controlled

output will be reduced. For best control the two part loads must be of equal

size. For wiring diagram and more information, see the instructions for the

TT-S1.

Start-up and fault finding

1. Check that all wiring is correct and that the sensor selector switches

are in the correct position.

2. Measure the resistance between terminals L1out - L2out, L1out - L3out

and L2out -L3out:

At 230V phase-phase voltage: 10.6Ω<R<66.4Ω.

At 400V phase-phase voltage: 18.4Ω<R<115Ω.

3. Connect supply voltage and turn the setpoint knob to the maximum

value. The LED on the TTC2000 should be continuously on or pulse on/

off with longer and longer ontime and eventually be continuously

on.Turn the setpoint to the minimum value. The LED should be

continuously off or pulse on/off with longer and longer offtime and

eventually be continuously off. At a certain position (within the

proportional band) the LED will pulse On-Off as the TTC2000 pulses

current to the heater. The pulse cycle period is approx. 6 -120 seconds

depending on the setting of the CT-potentiometer. Check with a clamp-

on ammeter that current is flowing to the heater.

Something wrong?

4. Remove wiring to external sensor (and setpoint if any). Measure

the resistance of the sensor and setpoint separately. The potentio-

meter resistance varies 0- 5kΩ between the lower and upper end-

point. The sensor resistance varies between 10kΩand 15kΩ

between the upper and lower ends of the sensor temperature

range. I.e. a TG-K330 has 15kΩat 0°C and 10kΩat 30°C. The

resistance changes by 167Ω/°C.

5. Leave the sensor terminals unconnected. Set all switches in the

downward position. Switch the voltage on.

TTC2000 should give full uninterrupted power and the LED should

be lit. Check with a clamp-on ammeter that current is flowing to the

heater.

If the LED is not lit and no current is flowing: Check that you have

power on terminals L1in, L2in and L3in and recheck the positions

of the sensor selector switches. If OK the TTC2000 is probably

faulty.

If the LED lights up but no current is flowing: Recheck the heater

resistance as above. If OK the TTC2000 is probably faulty.

6. Shut off power and short-circuit the sensor input 1 and 4. Switch

on power again.

TTC2000 should not give out any power at all and the LED should

be extinguished. Check with a clamp-on ammeter that no current is

flowing to the heater.

If the LED is extinguished but current is flowing to the heater the

TTC2000 is faulty.

If the LED is lit, recheck the shorting of the sensor input terminals. If

OK the TTC2000 is faulty.

7. If everything is OK this far the TTC2000 and the sensor/setpoint

are OK.

Shut off power, remove the wire strap from the the sensor input

terminals and reconnect external sensor(s) (and setpoint if

any).Set the switches to their correct positions. Connect power.

EMC emissions & immunity standards

This product conforms with the requirements of European EMC

standards CENELEC EN 50081-1 and EN 50082-1 and carries the

CE mark.

LVD

This product conforms with the requirements of the European

LVD standards IEC 669-1 and IEC 669-2-1.

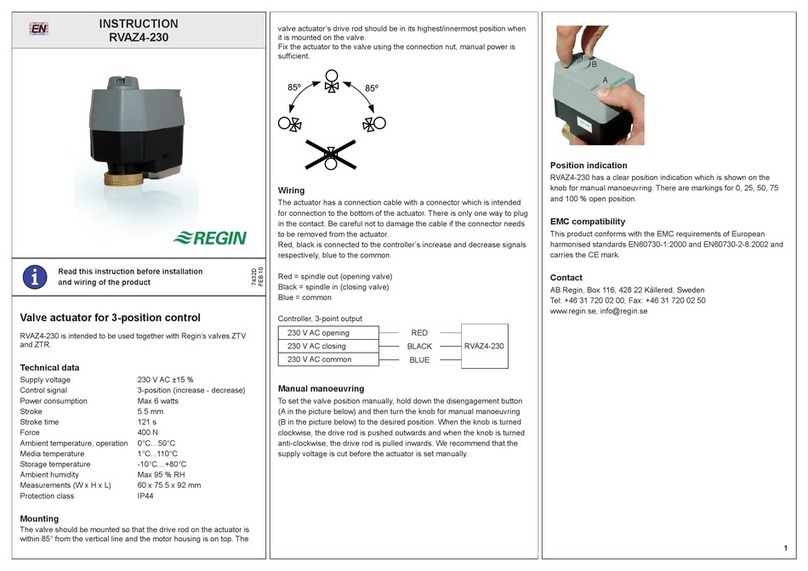

Fig 6

Fig 7

Fig 8

12

3

2

TG-K3xx

TG-G1xx

TG-R4xx

3 4

12

2

1

TG-K3xx

TG-G1xx

TBI-xx

3

4

Fig 9

7

0-10V DC in

Signal neutral

8 9

Remove

wire

TG-K360

5 6

Fig 5

12

TG-K3xx

TG-G1xx

3 4

Fig 4

12

3

1

TG-R4xx

3 4

12

2

1

3 4

TG-R5xx

TG-R3xx

Fig 3