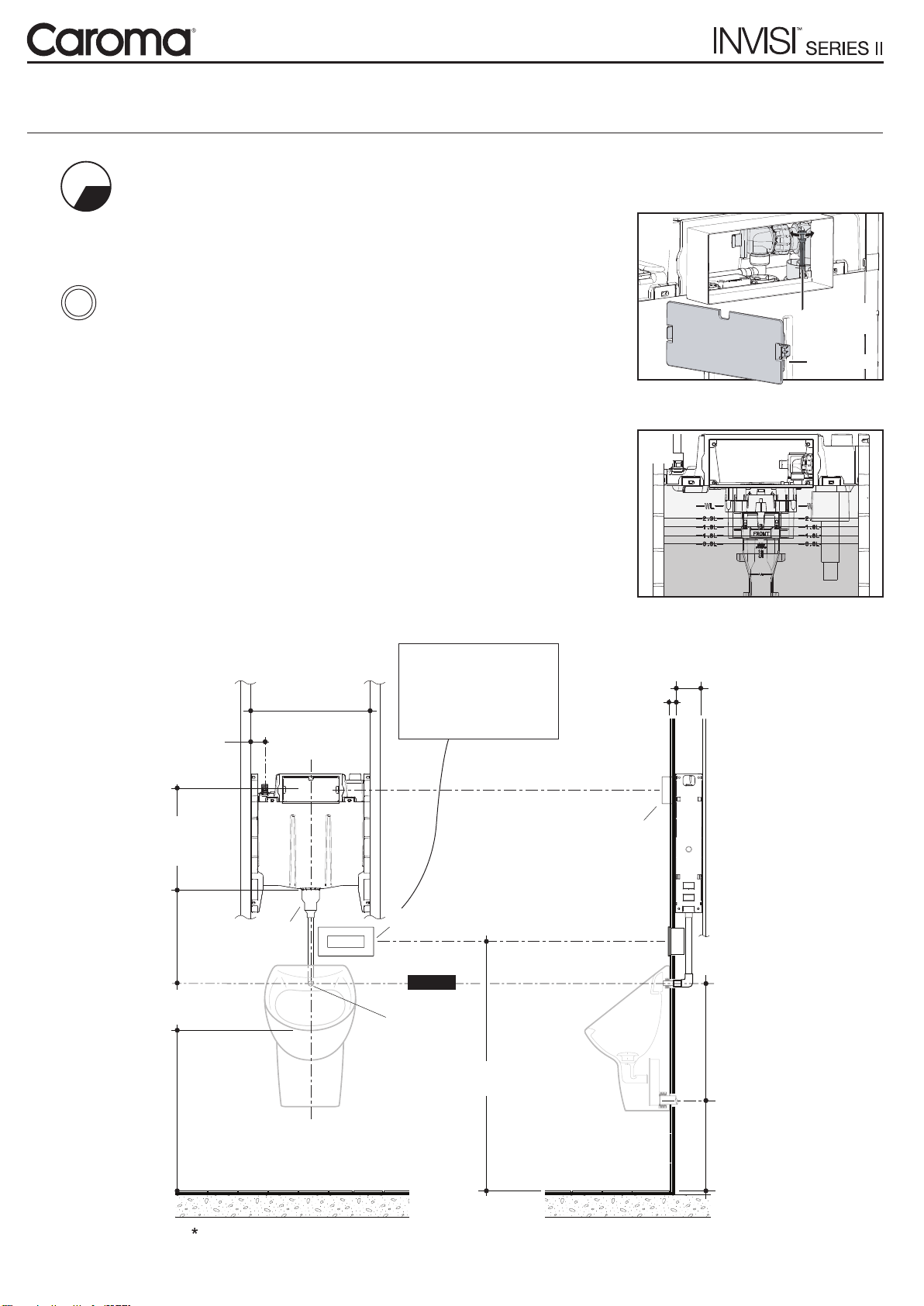

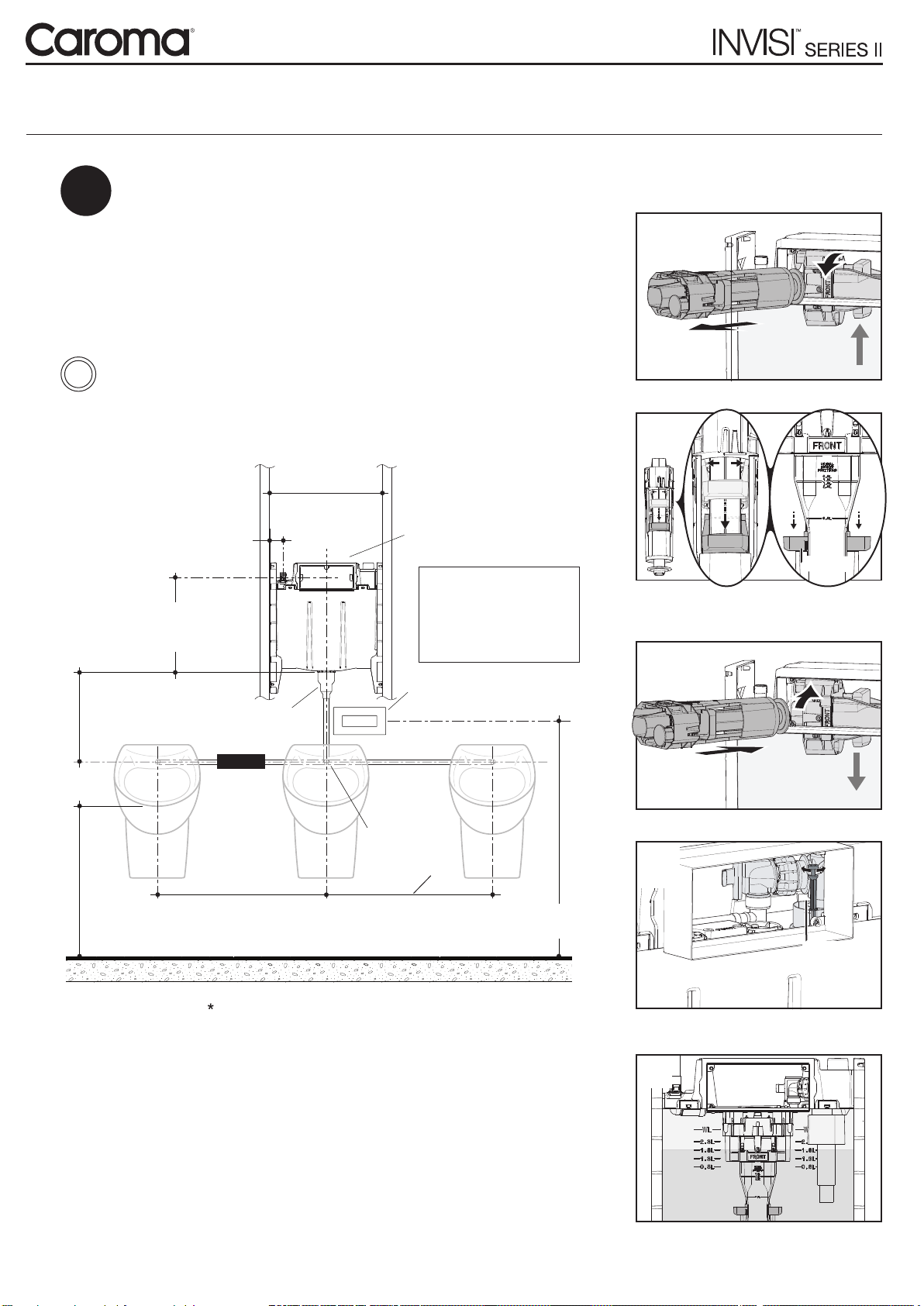

Button Service Access Options

34

29

200 - 210 Frame

Wall

Pipe

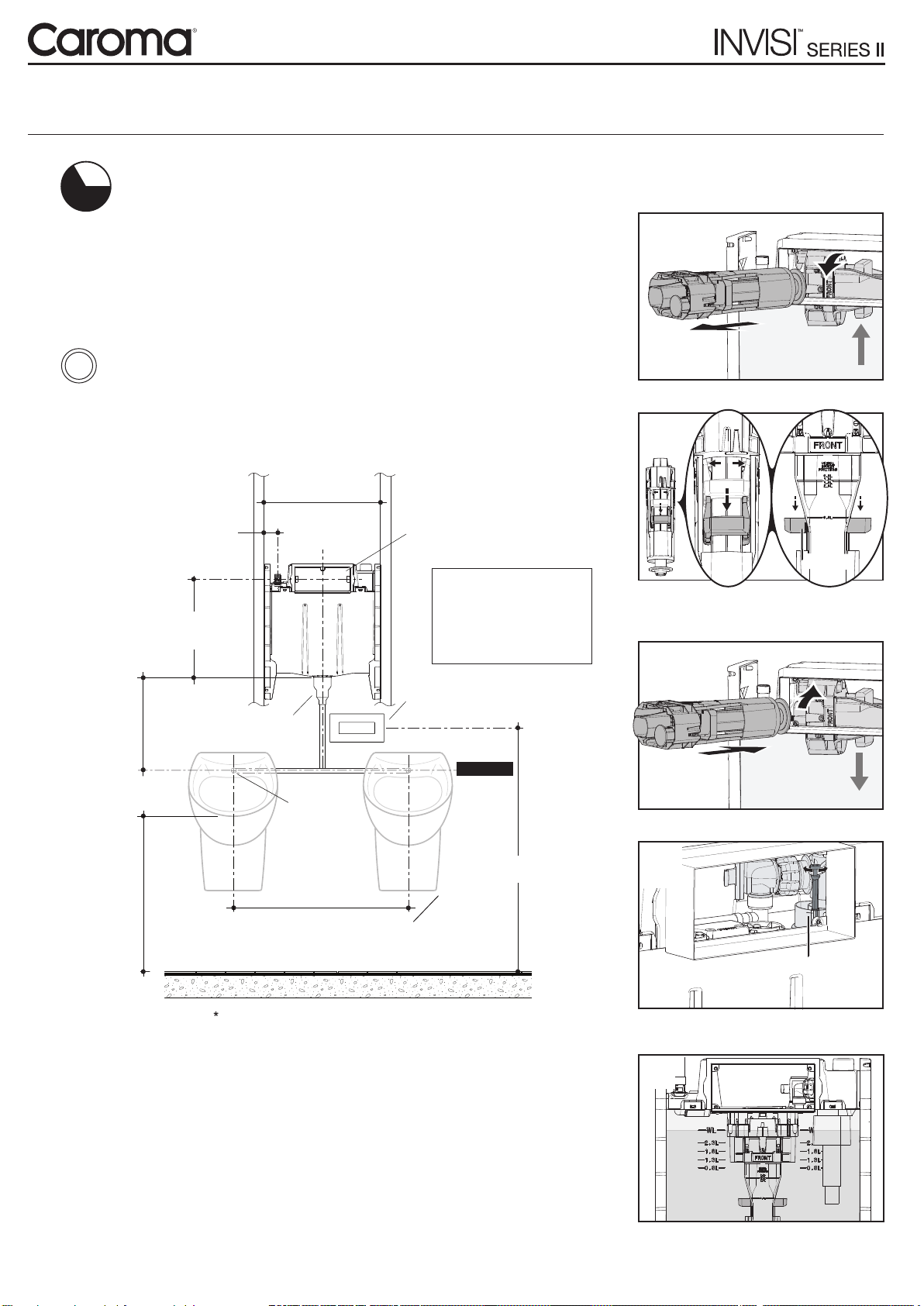

IMPORTANT - Does your urinal flush for more than 20 seconds?

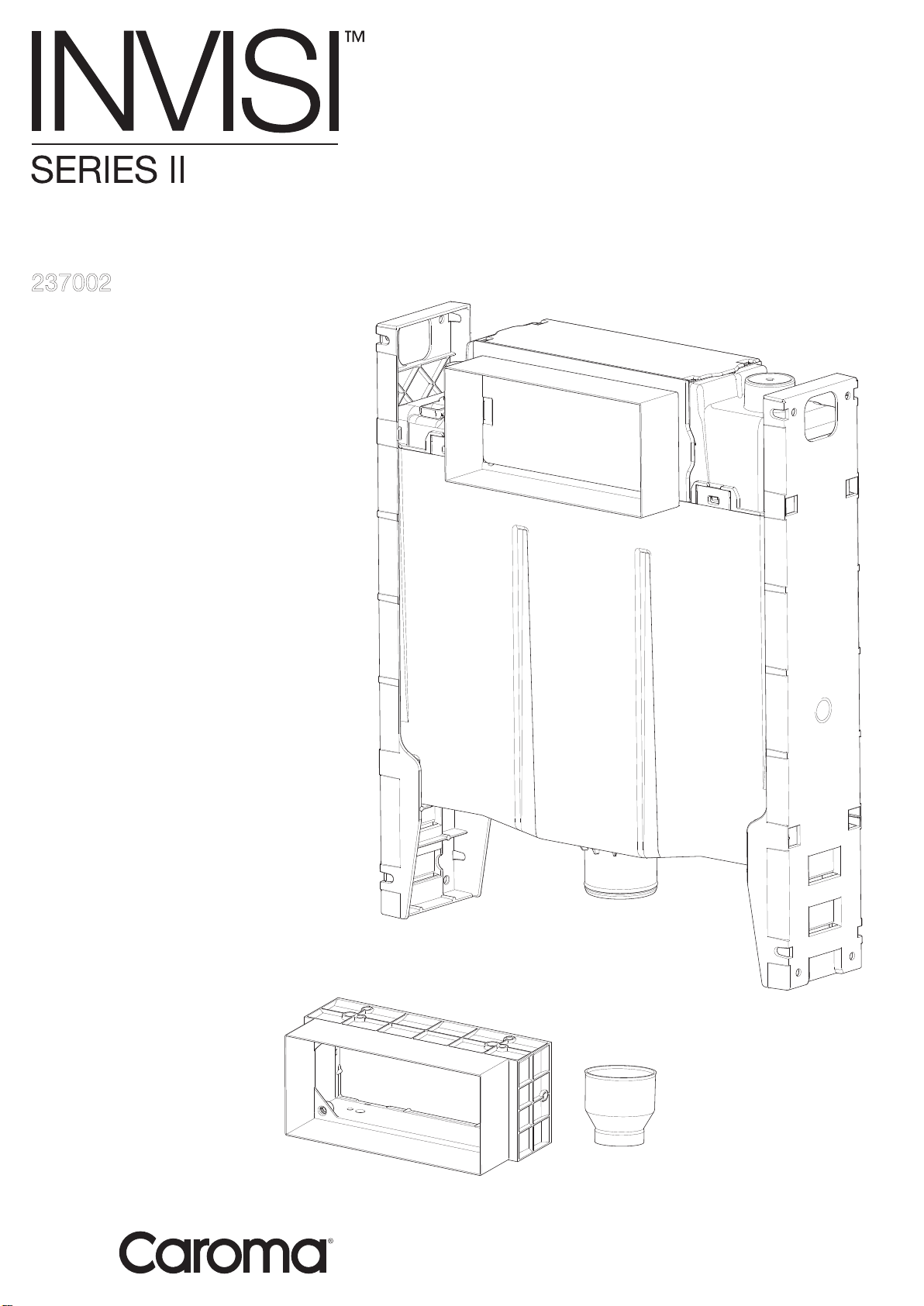

Cistern Service Access Options

Direct Panel Mounting

This is suitable for use with any

of the button panel kits.

Requires a 5mm minimum -

45mm maximum cladding

thickness.

Access to the cistern internals

is provided through the panel

window.

Remote Panel Mounting

This is suitable for use with any

of the button panel kits.

Suits up to 45mm cladding

thickness.

A Blanking Panel is required

for inwall access to cistern

internals.

Remote Button Mounting

Access to the rear of the buttons

must be provided for servicing.

Suitable for mounting through

panels up to 55mm thick.

A Blanking Panel is required for

inwall access to cistern internals.

Large Button Panel

Used in combination with Round

Remote Buttons allows access to

the whole cistern.

With some urinal types it is possible for the discharge rate to be slower than the rell rate. When the cistern is

ushed, the water level will begin to fall until the inlet valve opens. When water is added faster than it can leave,

the cistern never empties (the outlet valve remains open and the cistern runs on).

The ush volume required for each urinal stall is 1.5 - 2.5 litres. This amount of water passes relatively slowly

through the spreader system of some urinals, (as slow as 2 litres/min) which is normally slower than the

cistern rell rate. If a urinal installer does not consider this issue it is possible that cistern run-on will occur.

There are a number of checks to ensure that the urinal operates correctly:

1. Ensure that the ush volume is correctly adjusted

for the installation.

2. Where the urinal ushes for more than 20 seconds,

the inlet valve ow rate must be reduced. This is

achieved by carefully adjusting the Isolating Tap

to restrict the incoming ow.

3. Flush urinal several times to conrm settings.

NOTE: In some instances, particularly single stall

urinals, it maybe necessary to adjust the Isolation

Taps ow rate down very low (almost to the off position).

OFF

ON

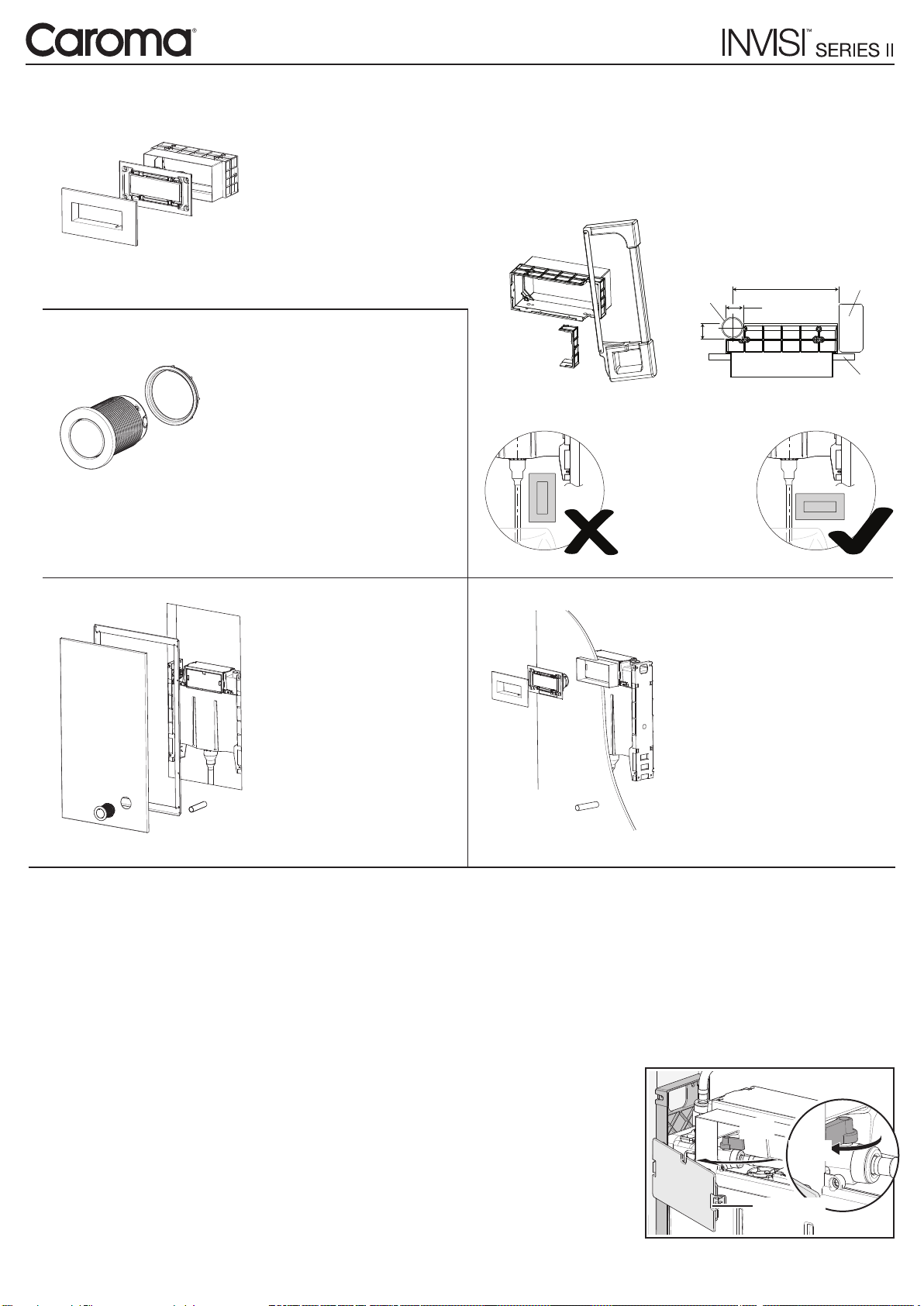

Dust Cover

INSTALLATION NOTE:

When installing between the copper pipe and the wall frame you

may need to modify the Remote Mounting Box for

optimum tment.

Using a hacksaw cut away the

corner adjacent to the pipe

WARNING:

Do not install the

Remote Mounting

Box vertically