6

ROUTINE MAINTENANCE & CARE

FOR THE EQUIPMENT OWNER

While some maintenance can be performed by laymen,

most should be performed by skilled, experienced

personnel. Follow the recommended service maintenance

schedule, and modify it as necessary for your

application/environment. For instance, dusty areas may

require more frequent filter changes.

After performing any maintenance or service on the unit,

be sure all panels are securely fastened in place to prevent

rain from entering unit cabinet and to prevent disruption

of the correct unit airflow pattern.

FIRE AND EQUIPMENT DAMAGE HAZARD

Failure to follow this warning could result in personal

injury and damage to equipment.

Do not use this unit if any part has been under water.

Immediately call a qualified service technician to

inspect the unit and to replace any part of the control

system and gas control that has been under water.

!WARNING

To ensure proper functioning of the unit, flow of

combustion and ventilating air must not be obstructed

from reaching the unit. Follow service and performance

clearances as listed in the product data.

Consider the following information before maintaining or

servicing equipment:

Compressor

All compressors are factory supplied with a normal charge

of the correct type refrigeration--grade oil in them and

should not require additional oil.

Indoor Air Filter(s)

Indoor air filter(s) should be checked every 3 or 4 weeks

(application dependant) and changed or cleaned when

necessary. See Figs. 19 and 20 for air filter access panel

locations. See Table 1 for replacement filter dimensions.

FIRE AND EQUIPMENT DAMAGE HAZARD

Failure to follow this warning could result in personal

injury and damage to equipment.

Never operate unit without filters in place. The

accumulation of dirt, dust or lint on the internal parts

of your unit can cause fire or a loss of efficiency.

Damage to the blower motor and/or compressors

could also result.

!WARNING

Filter Replacement — 48HC Base Unit

1. Remove the screws securing the filter access panel.

2. While holding filters, tilt upper filter rack.

3. Remove filters by pulling up and out toward you from

the track.

4. Inspect filters. Clean or replace as necessary.

5. Follow direction of airflow arrows as noted on filter

frame when returning filters to rack.

6. Reinstall air filter access panel.

Filter Replacement — ERV Unit

1. Rotate the latches on the ERV access door and open

the door.

2. Slide out the supply and exhaust air filters.

3. Inspect filters. Clean or replace as necessary.

4. Direction of airflow is left to right on the lower filters

and right to left on the upper filters as viewed into the

ERV section when the door is open.

5. Close ERV access door and secure by rotating the

latches.

If you have difficulty in locating your air filter or if you

have questions concerning proper filter maintenance,

contact your dealer for instructions. When replacing your

unit filters, always use the same size and type of filter that

was originally supplied by the installer.

Units with outdoor air capability have a cleanable filter

for the outdoor air. This filter should be checked

semi--annually and cleaned as necessary with steam or hot

water and a mild detergent. Do not use throwaway filters

in place of cleanable filters.

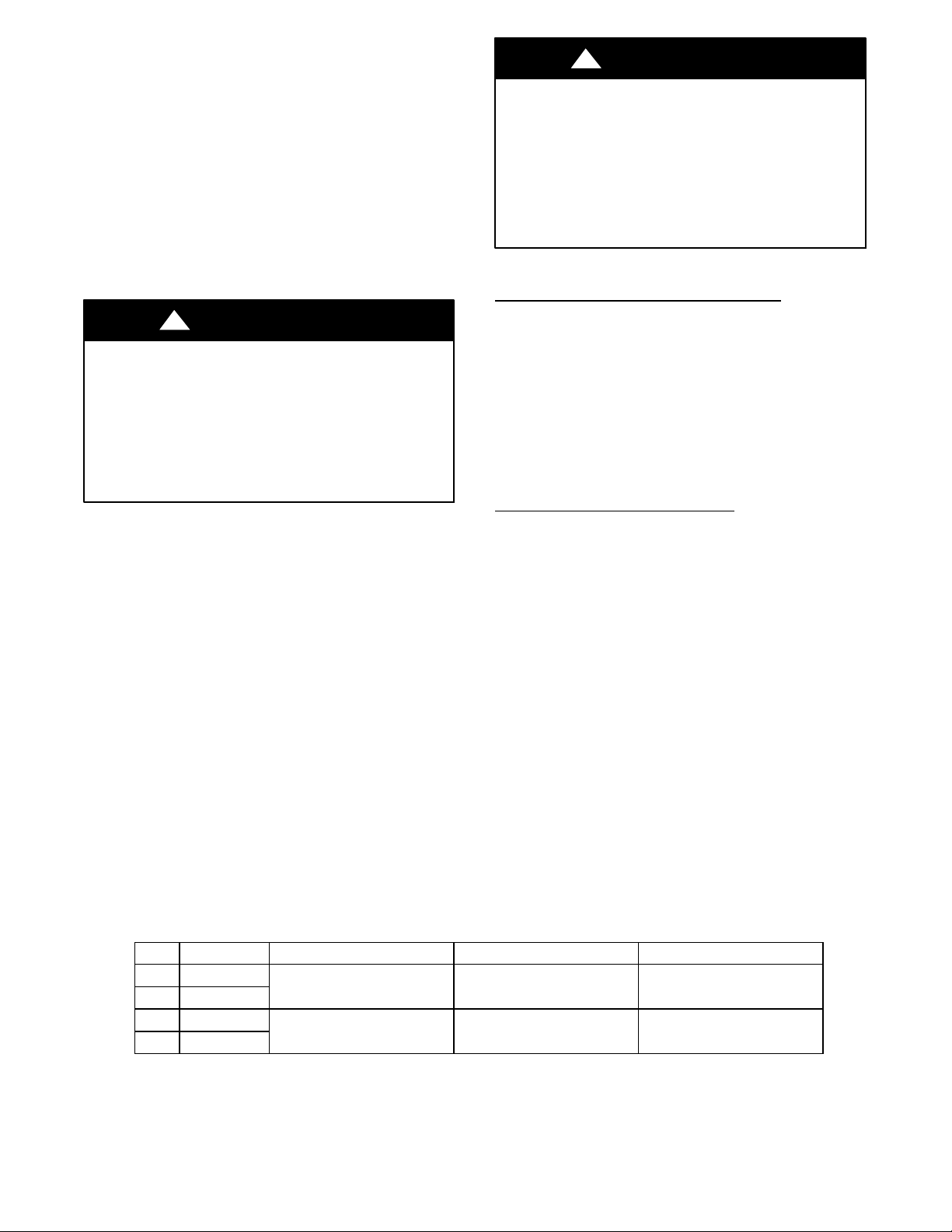

Table 1 – Replacement Filters -- Size and Quantity

Size Capacity 48HC Base Unit ERV Supply Air Filters ERV Exhaust Air Filters

17 15 tons 20x25x2(6) 20x16x2(2) 20x16x2(2)

20 17.5 tons

24 20 tons 16x25x2(9) 16x25x2(2) 16x25x2(2)

28 25 tons

NOTE: Filter sizes in Table 1 are in inches. Numbers in ( ) denote filter quantity.