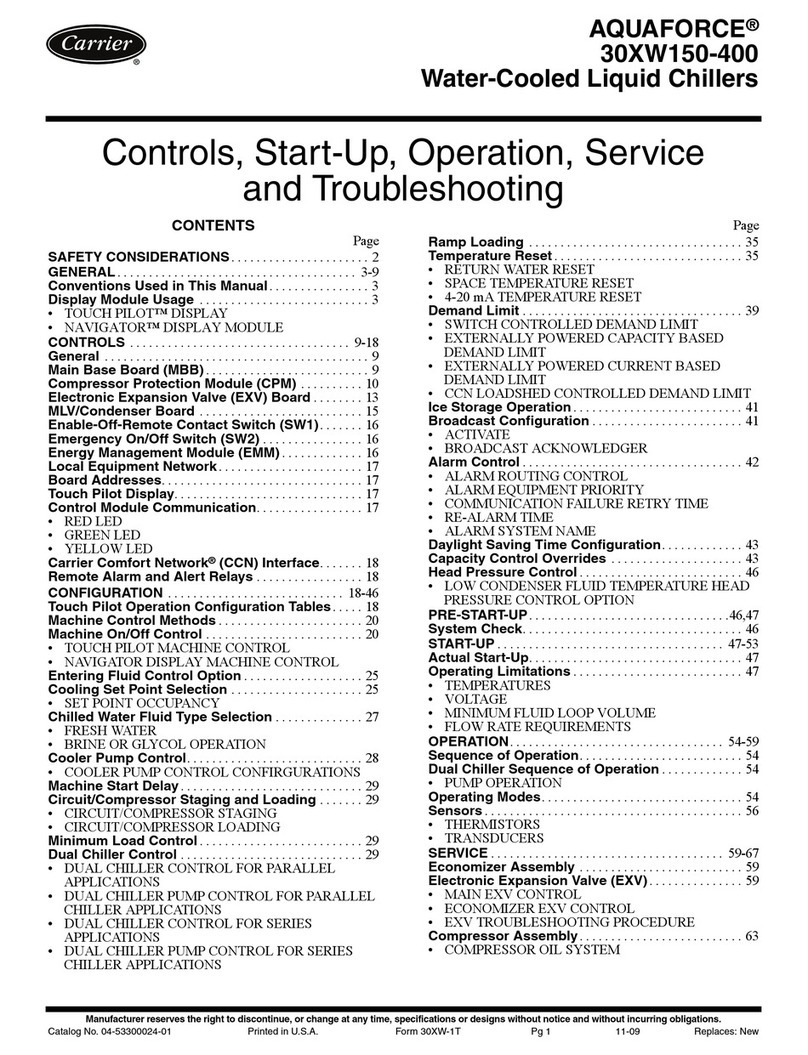

CONTENTS Page

SAFETY CONSIDERATIONS ...................1

INTRODUCTION ..............................2

General ......................................2

Job Data ....................................2

RECEIVING THE CHIILLER ...................2,3

Identify Chiller ...............................2

Inspect Shipment ............................2

One-Piece Chillers: Check Shipping

Vacuum ...................................2

Two-Piece Chillers: Check Shipping

Pressure ..................................2

Provide Chiller Protection ....................2

RIGGING AND POSITIONING .................3-8

Rig One-Piece Units ..........................3

Rig Two-Piece Units ..........................3

• PREPARATION

• RIGGING

Position and Level the Equipment ............8

CHIILLER ASSEMBLY .......................8-10

Assemble Two-Piece Units ...................8

Purge Exhaust Assembly .....................8

Chiller Leak Test .............................8

Chiller Evacuation ...........................8

Connect Water Piping ........................9

Install Steam and Condensate Piping ........10

Fusible Plug Drain Piping ...................10

Rupture Disc Piping .........................10

INSULATION AND PAINT .....................11

Insulation (If Required) ......................11

• COLD SURFACES

• HOT SURFACES

Final Paint Coat (If Required) ................11

CONTROLS AND WIRING ....................11

Two-Piece Chiller Connections ...............11

Chillers With Electro-Mechanical Controls ....11

• CAPACITY CONTROL VALVE(S)

• EXTERNAL WIRING

• SENSOR ELEMENTS

Chillers With PIC Controls ...................11

• CAPACITY CONTROL VALVE(S)

• EXTERNAL WIRING

• SENSOR ELEMENTS

INITIAL SOLUTION AND REFRIGERANT

CHARGING ...............................12

INTRODUCTION

General — The 16JT chiller is factory assembled, wired,

and leak tested. Installation (not by Carrier) consists prima-

rily of establishing water, steam, and electrical services to

the chiller. Rigging, installation, insulation, field wiring, and

field piping are the responsibility of the contractor and/or

customer. Carrier has no installation responsibilities for the

equipment.

Job Data — Necessary information consists of chiller lo-

cation drawings, piping drawings, field wiring diagrams, and

a rigging guide.

RECEIVING THE CHIILLER

Identify Chiller — The chiller model number and serial

number are stamped on the chiller identification plate. Check

this information against shipping papers and job data. For

information on model number nomenclature, see Fig. 1.

The 16JT comes with either electro-mechanical controls

or Product Integrated Controls (PIC), depending on when it

was manufactured.

If the last five digits of the serial number are 80XXX (where

XXX stands for the last three digits of the serial number),

the model comes with fusible plug drain piping and rupture

disc piping; if the last five digits are 92XXX, the model comes

with rupture disc piping only.

For 16JT chillers sizes 810 to 880, the evaporator and ab-

sorber are located side by side; for sizes 080 to 150 and 080L

to 150L, the evaporator is located above the absorber.

Inspect Shipment (Fig. 2) — One-piece chillers are

at a deep vacuum when shipped. Do not open any valves

until the vacuum has been noted. Refer to One-Piece Chill-

ers: Check Shipping Vacuum below.

NOTE: Chillers shipped in 2 pieces are under nitrogen

pressure.

Inspect for shipping damage while chiller is still on ship-

ping conveyance. If chiller appears to be damaged or has

been torn loose from its anchorage, have it examined by trans-

portation inspectors before removal. Forward claim papers

directly to transportation company. Manufacturer is not re-

sponsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify

the nearest Carrier Air Conditioning office if any item is

missing.

To prevent loss or damage, leave all parts in original pack-

ages until installation.

One-Piece Chillers: Check Shipping Vacuum —

To check for leaks that have occurred during shipment on

one-piece chillers:

1. Connect an absolute pressure gage to a service valve.

2. Record the absolute pressure of the assembly. If the ves-

sel pressure is greater than 0.28 in. (7 mm) of mercury,

the chiller has acquired a leak in shipping and must be

leak tested. Refer to the Chiller Leak Test section for

instructions.

Two-Piece Chillers: Check Shipping Pressure

—To check for leaks that have occurred during shipment

on two-piece chillers:

1. Connect a pressure gage (30 psig [200 kPa]) to a service

valve on each piece. Two-piece chillers are pressurized

with nitrogen to 5 psig (34 kPa).

2. If the vessel has lost its pressure, it has acquired a leak

during shipping and must be leak tested after positioning

and assembly. Refer to the Chiller Leak Test section for

instructions.

Provide Chiller Protection — If the chiller will not

be installed immediately, it is very important to use a drop

cloth or plastic cover to protect the chiller from construction

dirt and moisture before installation.Also, do not remove pro-

tective shipping cover on control panel until ready to use.

Fig. 1 — Model Number Nomenclature

2