off quickly. DO NOT hold the button on. The signal generated simulates that of a detected vehicle. No

response indicates component failure on the circuit board or failure of the power supply or a shorted probe or

cable. Disconnect probe wires from terminal strip and try again.

Special Note: After using the TRIP TEST button to test the circuit board, wait at least ten seconds before

re-testing. This allows time for the re-trigger hold-off timer to reset.

RE-TRIGGER HOLD-OFF

The new re-trigger hold-off circuit (Issue 3, July 2000 to present) allows both for a shorter annunciator time

and minimizes irritating multiple alarms. However, if you are working with an application not conducive to this

re-trigger hold-off feature, call Preferred’s technical staff on our 800 number for the disconnect procedure.

TRANSIENT SUPPRESSION

The CT-2B control unit transient suppressor circuit is already connected. The transient suppressor is

activated when the wire is connected to terminal No. 4. This circuit will reduce false alarms caused by

lightning. If difficulty occurs when setting the probe sensitivity, disconnect the wire from terminal No. 4 to de-

activate the transient suppressor.

ADJUSTING ANNUNCIATOR TIME

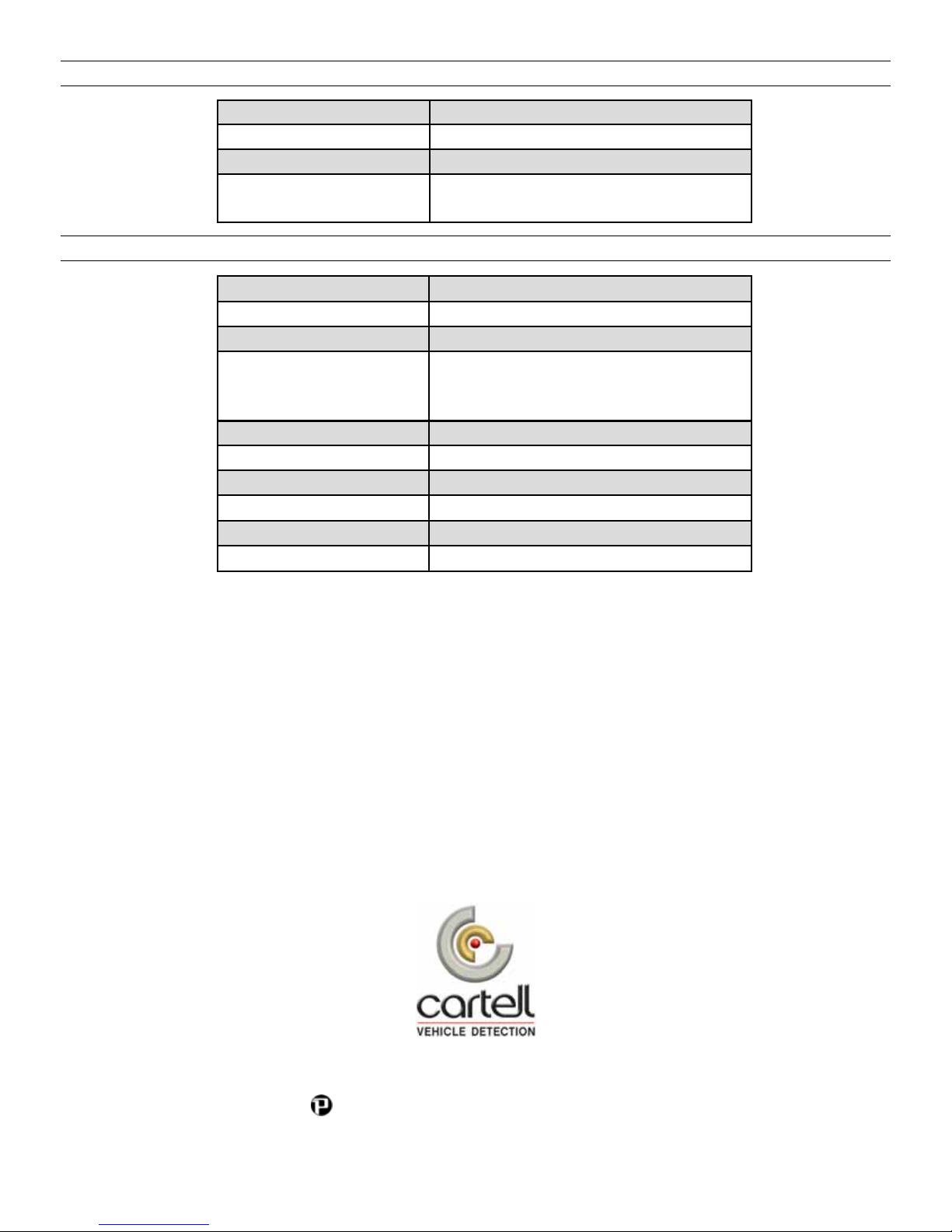

See Figure 1. This function controls the amount of time the customer desires the noisemaker(s) to stay on.

It may be adjusted to stay on anywhere from 2 to 20 seconds (Issues 1,2) or 1/2 to 15 seconds (Issue 3). To

adjust, use the potentiometer "A" (CW to increase time). Push the trip-test button to hear your adjustment.

Keep adjusting until the desired time is achieved.

ADJUSTING PROBE SENSITIVITY

See Figure 1 on page 1. Probe sensitivity is set at the factory and does not usually need to be adjusted.

Factory setting allows a single standard probe to cover a 12 foot wide driveway when installed beside it (see

"Installing Sensor Probe and Cable" on page 4). Increasing the sensitivity above the factory setting is not

recommended unless the probe is located in a low sensitivity area.

When the probe is placed in the center of the drive, sensitivity may be decreased considerably allowing the

probe to be installed closer to highway traffic, power lines, etc.

To adjust probe sensitivity, turn the potentiometer "B" fully counter clockwise and adjust clockwise in small

increments. Use a small, slow moving vehicle to test sensitivity. Have it pass the probe and adjust the

potentiometer between each pass. Stop adjusting at the point where the small car trips the system each time

it passes the probe.

EXTRA SET OF RELAY CONTACTS

See Figure 1 on page 1. The annunciator relay has a second set of free SPDT contacts that connect to

terminals No. 5, 6, and 7. The contacts may be used to trip a dialer, alarm panel, home automation panel,

transmitter, X-10 interface module, etc.

HOOKING TO AGATE OPERATOR

See Figure 1 on page 1. The CT-2BG control unit can be used to trigger a gate operator by using the free

set of relay contacts #6 (Common) and #7 (Normally Open). These contacts are to be connected to the

momentary input terminals of the gate operator, typically the key pad input or RF radio receiver input. The

time adjustment for the relay adjustment "A" should be set at its minimum setting. Longer relay time may be

necessary for those installations where the vehicle stops, then restarts near the sensor probe after the gate is

open.

ANNUNCIATION IN THE HOME WHEN USED WITH GATE

In addition to tripping the gate operator, the CT-2BG can be used to trip a sounder inside the home. Run a

wire to the gate operator from the home and use the extra set of relay contacts to trip the sounder inside the

home. For more information, contact technical support by calling Preferred Technologies Group at 800-223-

4743.

2

Back to Table of Contents

Back to Table of Contents

Back to Table of Contents

Back to Table of Contents

Back to Table of Contents

Back to Table of Contents

Back to Table of Contents