10

HOLDING CABINET NORMAL OPERATION (CONT)

CAUTION:

HOT SURFACE

Inner surfaces of the unit

will be very hot during and

after operation.

Avoid touching the cabinet

when loading or removing

product.

Low temperature alarm

The cabinet is equipped with a low temperature alarm feature. When the

alarm is active, the temperature display will indicate “LO” and then “TEMP”

and the audible alarm will sound. To silence the alarm, press the “alarm off”

button. If the actual temperature is still below the low temperature alarm set

point after 5 minutes, the alarm will sound again.

This alarm can be triggered by the door being left open, product that is much

colder than the temperature set point being placed in the cabinet or due to a

malfunction of the heating system.

To change the low temperature alarm set point, press and hold the “alarm off”

button while adjusting the temperature set point knob to the new desired val-

ue. Due to food safety concerns, the low temperature alarm should nev-

er be set below 140 degrees F (60°C).After 3 seconds, the controller will

accept the new set point. The new value will be stored in the controller

memory until the next time the value is changed.

The audible alarm for low cabinet temperature can be turned off. The factory

default is ON. To enter into the adjustment mode, push in and hold the

“alarm off” button until the alarm sounds. The display will read either (ON or

OFF). To change the status, push the temperature knob, which will function

as a toggle switch to select between ON or OFF. After 10 seconds, the con-

troller will accept the desired audible alarm function (either ON or OFF). If

OFF is selected, the temperature display will still indicate “LO” and “TEMP” if

the low temp alarm is tripped.

Low Water Alarm

The cabinet is equipped with a low water alarm feature. When water drops

below the low level probe, the control cuts power to the heating element used

to produce steam. If the water level is below the low probe for more than 5

minutes, an audible alarm will sound and the humidity display will indicate

“LO” and then “H2O”. This alarm can be triggered by a lack of water supply

or due to a malfunction of the humidity system.

The humidity display will normally show the set point value. To display the

actual humidity value, press the knob located next to the humidity display.

The actual temperature and humidity values will be displayed for 5 seconds

and then revert back to the respective set point values. To display only the

actual temperature or humidity, push in the respective adjustment knob.

The audible alarm for low humidity can be turned off. The factory default is

ON. To enter into the adjustment mode, push in and hold the (alarm off) but-

ton until the alarm sounds. The display will read either (ON or OFF). To

change the status, push the humidity knob, which will function as a toggle

switch to select between ON or OFF. After 10 seconds, the controller will

accept the desired audible alarm function (either ON or OFF). If OFF is se-

lected, the humidity display will still indicate “LO” and “H2O” if the low water

alarm is tripped.

Operating ranges:

-temperature: 90-200ºF (32-93ºC)

-temp alarm: 80-180ºF (27-82ºC)

-relative humidity: Off - 90%

The LO / H2O alarm can be

silenced by pressing the

alarm off button or by add-

ing water to the reservoir.

If the alarm off button is

pressed and no water is

added, the alarm will sound

again after 5 minutes.

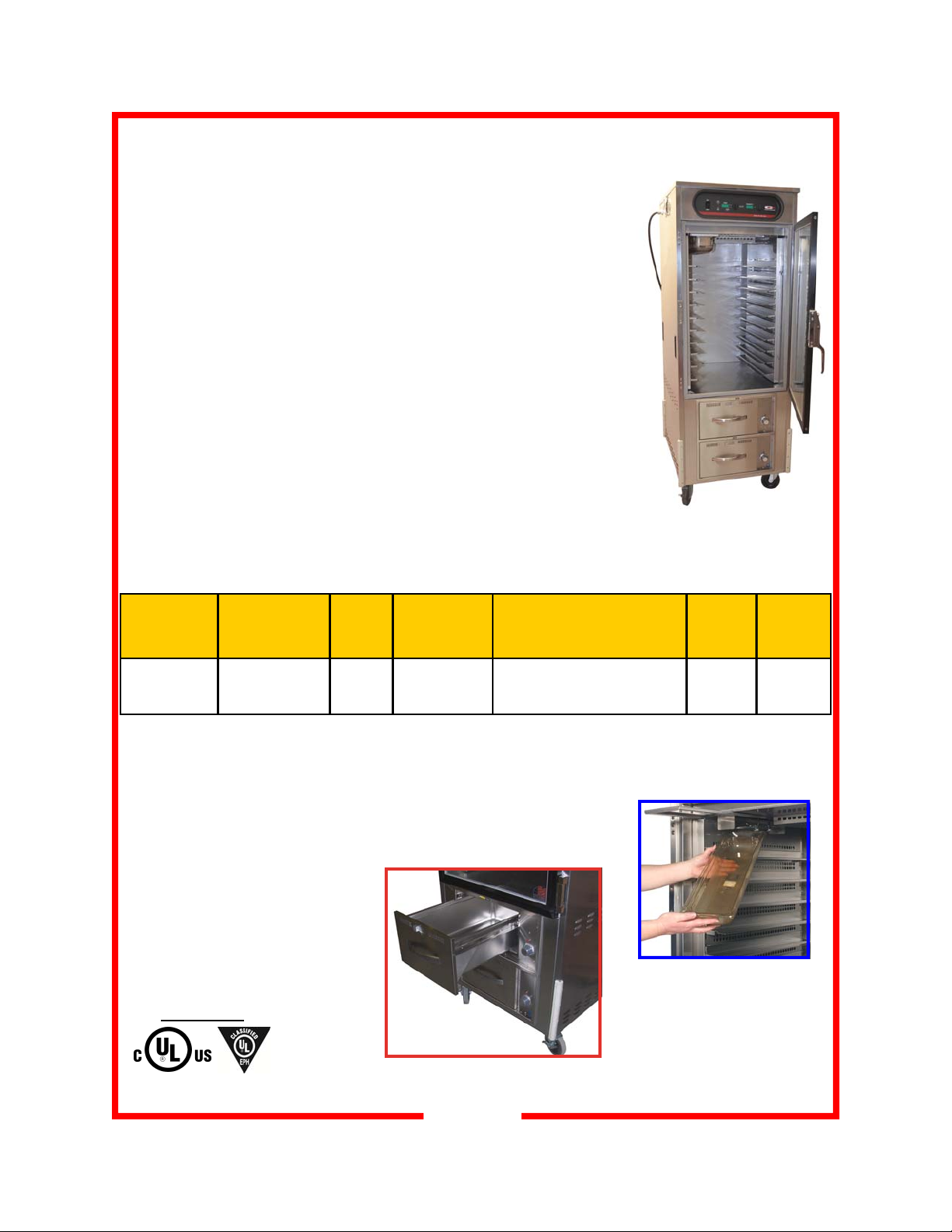

CAUTION:

WATER HAZARD

A water trough is located at

the base of the door to col-

lect condensation. Make

sure to periodically check

and empty it regularly to

avoid overflow. The trough

can be removed and emp-

tied by simply sliding it off

the bolts at the base of the

door.

Factory default setpoints:

- temperature: 160ºF (71ºC)

- humidity: 50%

- low temp alarm: 140ºF (60ºC)

- high temp alarm: 240ºF (115ºC)

- temp alarm: ON

- humidity alarm: ON