5

CONSTRUCTION...All stainless steel double

wall cabinet construction. Black rubber legs.

Modular design with one controller and one

pan cavity per module.

CABINET MATERIAL...All stainless steel;

20 gauge polished exterior. Each cavity has

a scratch-resistant polymer lower surface

with recessed aluminum plate. Angle slides

keep plastic lids in place. Lids are remova-

ble for holding drier foods and cleaning.

CABINET CAPACITY... Capacity and pan

size(s) accepted depend on model (refer to

individual specification sheets). Pass-thru

design for access from front and back.

LIDS... Spring-loaded, polycarbonate lids or

metal lids, depending on model number.

Easily removed, without tools, for easy

cleaning or holding uncovered food prod-

ucts. Lids in place provide seals for pans

containing moisture-sensitive food products.

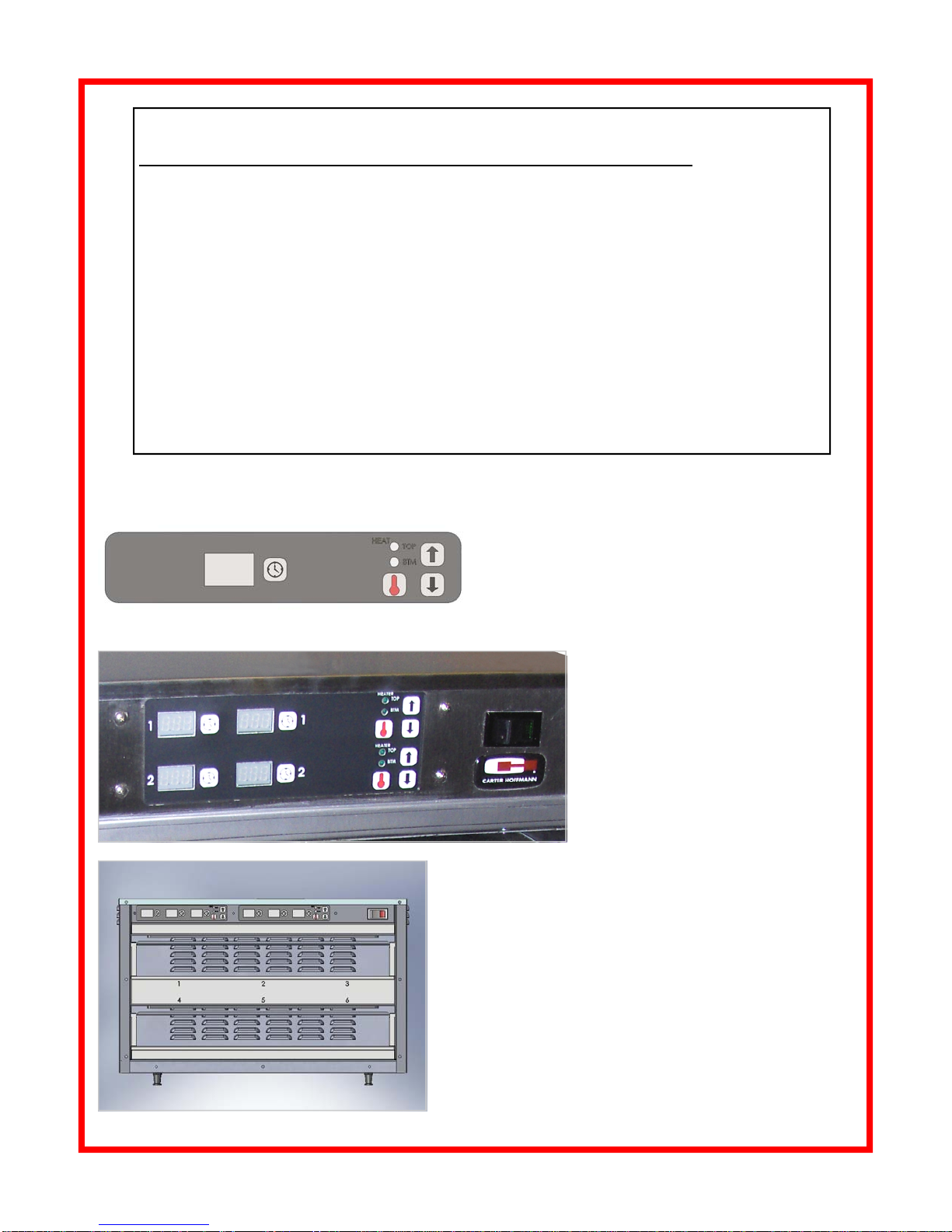

CONTROLLER... Electronic temperature

controls with countdown timer and audio/

visual alarm. One controller per pan cavity.

Allows user to program temperature in one

degree increments up to 225°F (107°C).

Timer can be set for up to 99 minutes, in 1

minute increments. Countdown will convert

to seconds when less than one minute is left.

HEATING SYSTEM... For each module

there are two 200, 250 or 300 watt silicone

pad heater vulcanized to bottom of alumi-

num plate. One mounted to the top of each

cavity and one mounted to the bottom of

each cavity. Programmable controller, with

a digital temperature and time display.

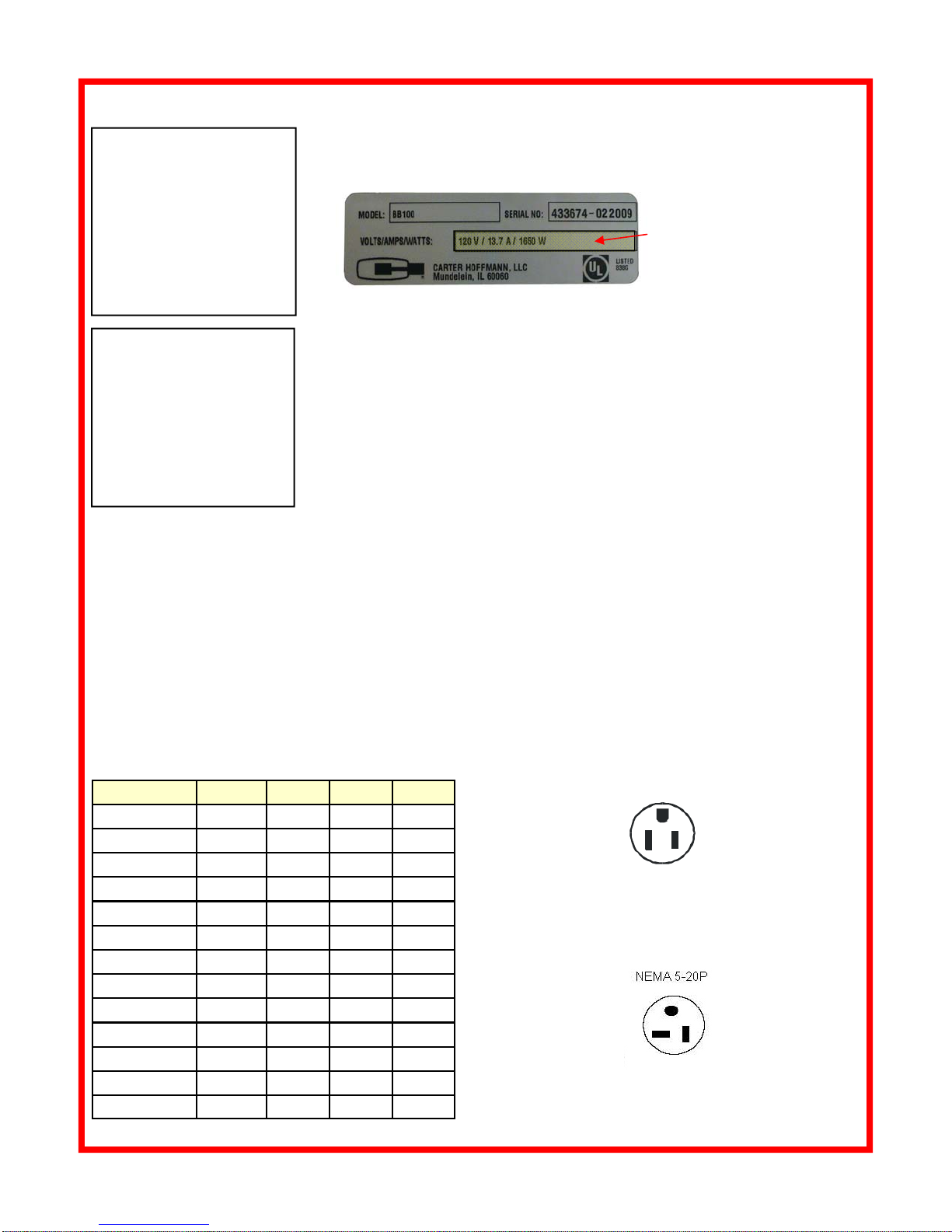

ELECTRICAL CHARACTERISTICS…

Operates on 120 volts, 60 cycle, single

phase, 200, 250 or 300 watts per zone, am-

perage varies in relation to number of zones.

Ten foot 3 wire rubber cord with 3 prong

grounding plug. NEMA 5-15P. MZ423GS-2T

operates on 208v, 2000 watts, 9.6A, NEMA

6-20P. See individual specification sheets for

detailed electrical specifications.

PERFORMANCE...Capable of heating to

195°F (91°C). Temperature default is 195°

F. Preheat to 180°F (82°C) in less than 10

minutes.

OPTIONS & ACCESSORIES...

►Pans with handles (specify size)

►Contact factory for additional non-standard

module configurations

INTRODUCTION

Carter-Hoffmann MZ Modular Holding Cabinets are designed to hold pre-cooked crispy or moist food products at temperature. Hold-

ing times and temperatures are controlled by an electronic controller and are individually programmable for each module. Timer can be

set in one minute increments up to 99 minutes. Temperature can be set in 1ºF increments up to 225ºF (107°C).

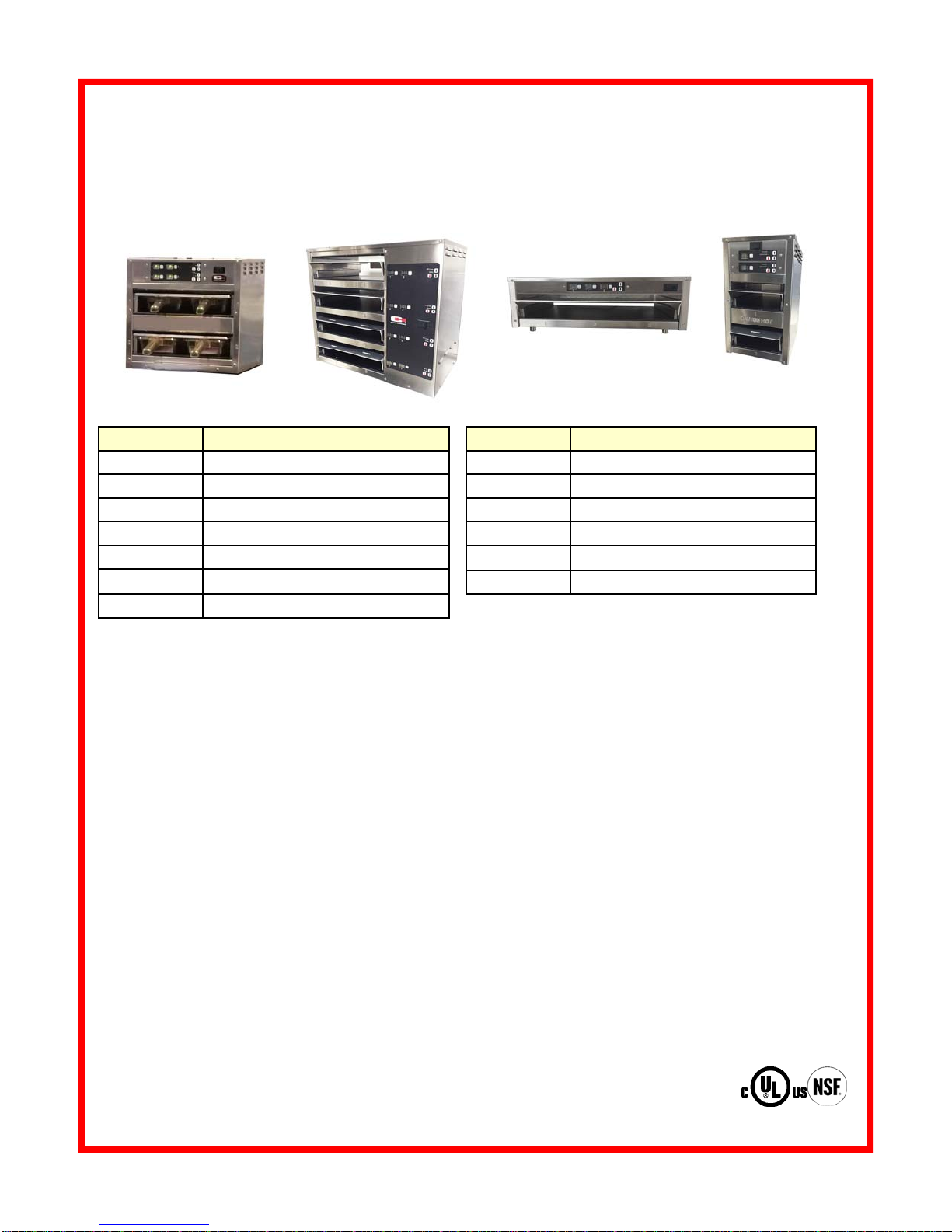

MZ SERIES MODULAR HOLDING CABINET SPECIFICATIONS

MODEL PAN CAPACITY

MZ112S-2T 1 full size, 2 half size or 3 1/3 size (2.5” deep)

MZ212S-2T 2 full size, 4 half size or 6 1/3 size (2.5” deep)

MZ1W2S Two 1/3 size (2.5” deep)

MZ2W2S Four 1/3 size (2.5” deep)

MZ223S-2T Four 1/3 size (2.5” deep)

MZ143S-2T Four 1/3 size (2.5” deep)

MZ243S-2T Eight 1/3 size (4” deep)

MZ223S-2T MZ423GS-2T

MZ112GS-2T

MZ213GS-2T

MODEL PAN CAPACITY

MZ112GS-2T 1 full size, 2 half size or 3 1/3 size (2.5” deep)

MZ212GS-2T 2 full size, 4 half size or 6 1/3 size (2.5” deep)

MZ213S-2T Two 1/3 size (2.5” deep)

MZ223GS-2T Four 1/3 size (2.5” deep)

MZ243GS-2T Eight1/3 size (2.5” deep)

MZ423GS-2T Eight 1/3 size (4” deep)