4

ROUBLESHOOTING

T

6828871-R1 EN

3.1 General Procedures

3.1-1 Truck System Requirements

• Truck hydraulic pressure should be within the range

shown in Specifications, Section 5.1. PRESSURE TO

THE ATTACHMENT MUST NOT EXCEED:

• Truck hydraulic flow should be within the range shown in

Specifications, Section 5.1.

• Hydraulic fluid supplied to the attachment must meet the

requirements shown in Specifications, Section 5.1.

3.1-2 Tools Required

In addition to a normal selection of mechanic's hand tools,

the following are required:

• In-line Flow Meter Kit:

10 GPM (37 L/min.) – Cascade Part No. 671476.

OR

20 GPM (75 L/min.) – Cascade Part No. 671477.

• Pressure Gauge Kit:

5000 psi (345 bar) – Cascade Part No. 671212.

• Assorted fittings, hoses, and quick-disconnect couplers

as required.

WARNING: Before servicing any

hydraulic component, relieve pressure

in the system. Turn the truck off and

move the truck auxiliary control valves

several times in both directions.

After completing any service procedure, test the

attachment through several cycles. First test the

attachment empty to bleed any air trapped in the

system to the truck tank. Then test the attachment

with a load to be sure it operates correctly before

returning to the job.

Stay clear of the load while testing. Do not raise

the load more than 4 in. (10 cm) off the floor while

testing.

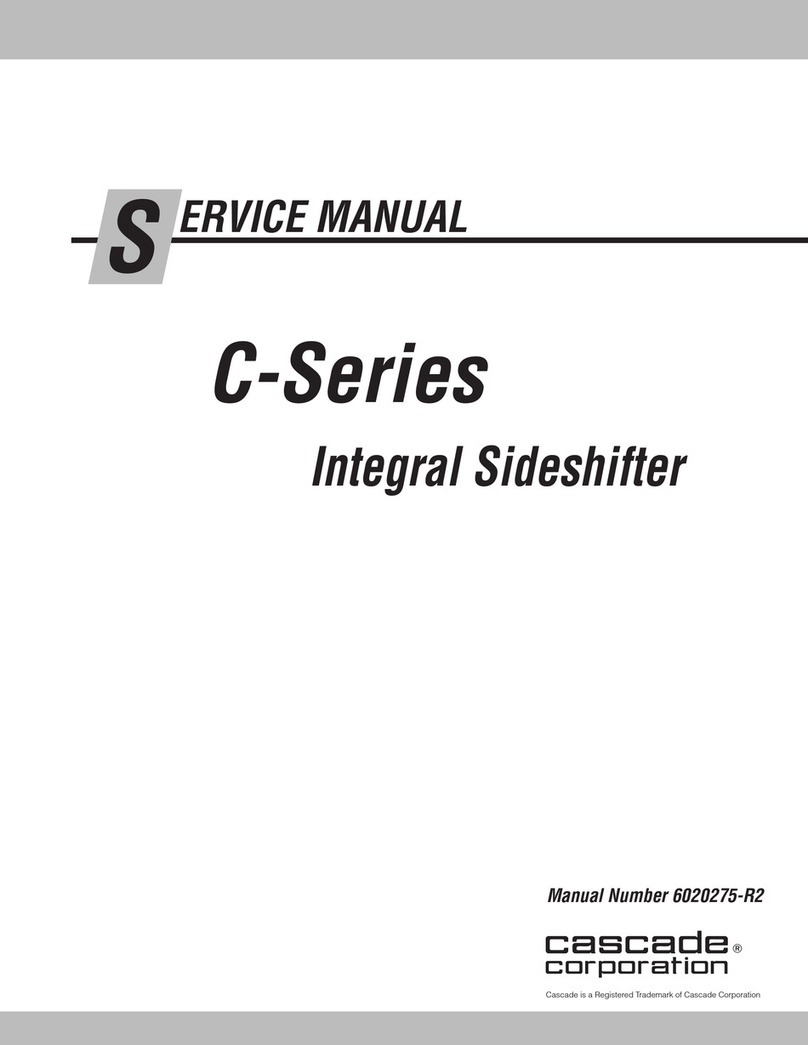

GA0014.eps

Flow Meter Kits

671476 – 10 GPM (37 L/min.)

671477 – 20 GPM (75 L/min.)

(2) No. 8

JIC/O-Ring Flow Meter

(2) No. 6-8

JIC Reducer

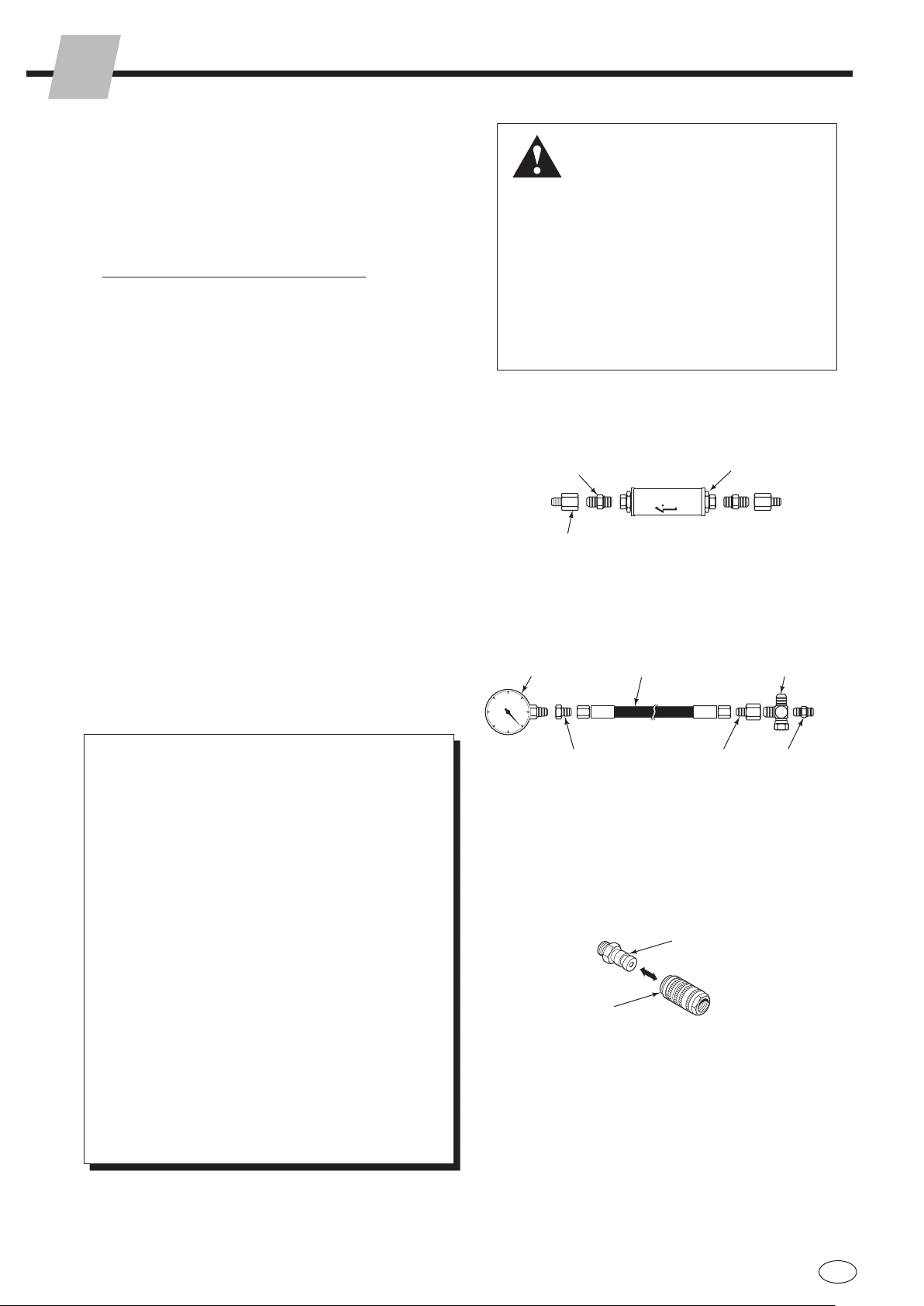

Pressure Gauge Kit

671212

Pressure

Gauge ▲No. 6-6 Hose ▲

No. 6 and No. 8

JIC Swivel Tee

No. 6-8 JIC

Reducer

No. 4, No. 6 ▲

and No. 8

JIC/O-Ring

No. 4-6

Pipe/JIC ▲

▲NOTE: Diagnostics Kit

394382 includes items

marked.

Male Straight Thread

O-Ring Coupler:

No. 4 (Part No. 212282) ▲

No. 5 (Part No. 210378)

No. 6 (Part No. 678592)

Female JIC Thread

Coupler:

No. 4 (Part No. 210385) ▲

No. 6 (Part No. 678591)

Quick-Disconnect Couplers

3.1-3 Troubleshooting Chart

Determine All The Facts

It is important that all the facts regarding the problem

are gathered before beginning service procedures.

The first step is to talk to the equipment operator.

Ask for a complete description of the malfunction.

Guidelines below and on the following pages can then

be used as a starting point to begin troubleshooting.

Clamp Circuit

• Attachment drops load after it has been picked up.

• Attachment will not carry load up to its rated

capacity.

• Attachment arms have uneven travel.

• Attachment arms travel slowly.

• Attachment arms will not move.

To correct these problems, see Section 3.3

Sideshift Circuit

• Attachment drops load while sideshifting.

• Attachment drops load at end of sideshift stroke.

• Attachment sideshifts left and right at different

speeds.

• Attachment will not sideshift

To correct these problems, see Section 3.4.

Model Maximum

80G-140G

Low Pressure 1455 psi (100 bar)

High Pressure 2760 psi (190 bar)

170G 2465 psi (170 bar)