ROUBLESHOOTING

6817684

T

4

3.1 General Procedures

3.1-1 Truck System Requirements

• Truckhydraulicpressureshouldbewithintherange

showninSpecications,Section5.1.PRESSURE TO

THE ATTACHMENT MUST NOT EXCEED 2300 psi

(160 bar).

• Hydraulicowshouldbewithinthevolumerangeas

showninSpecication,Section5.1.

• Hydraulicuidsuppliedtotheattachmentmustmeetthe

requirementsasshowninSpecications,Section5.1.

3.1-2 Tools Required

Inadditiontoanormalselectionofhandtools,youwillneed:

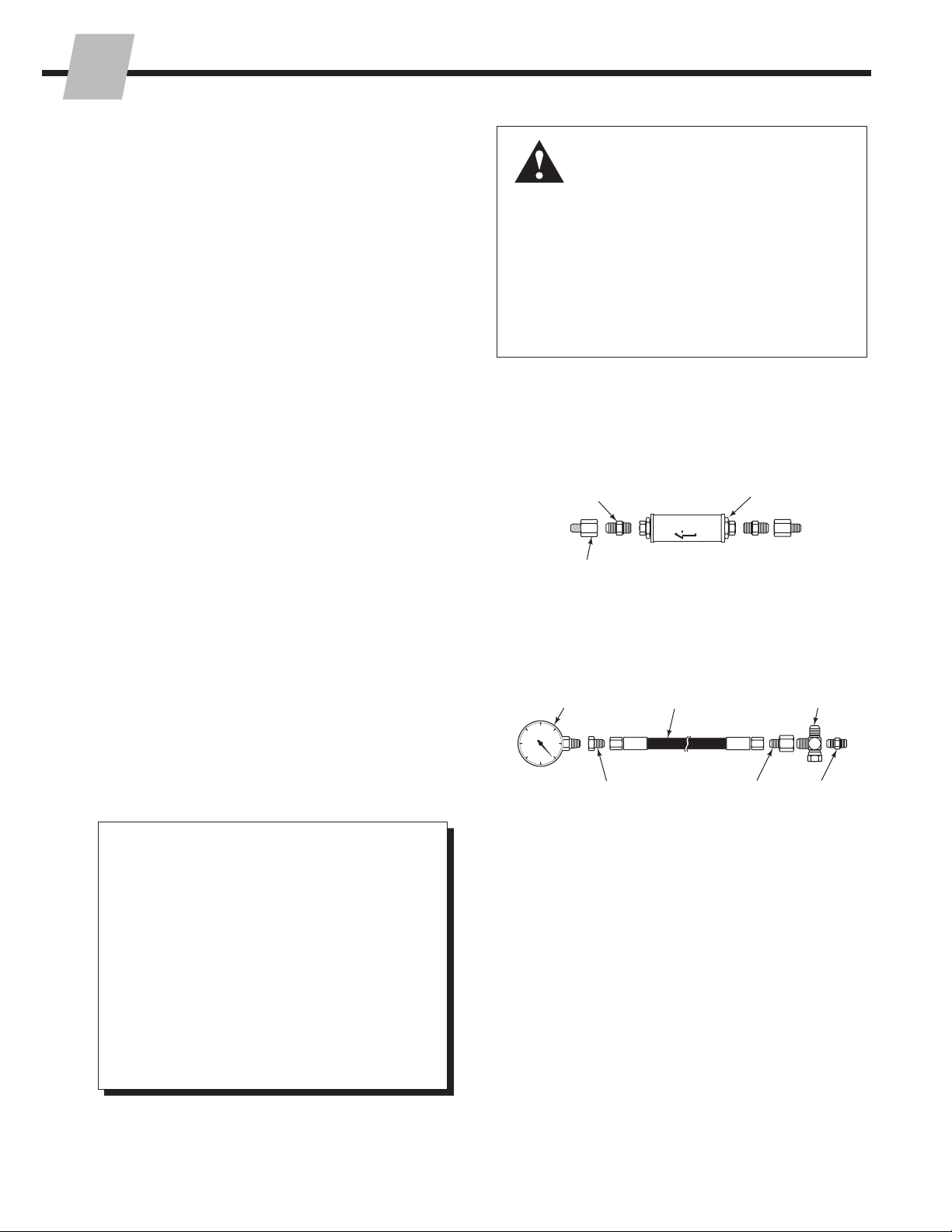

• InlineFlowMeterKit:

20GPM(75L/min.)–CascadePartNo.671477

• PressureGaugeKit:

5000psi(345bar)–CascadePartNo.671212,twokits

required.

• Assortedttingsandhosestoadaptgaugesandow

metertothecomponentsbeingtested.

3.1-3 Troubleshooting Chart

Determine All The Facts –Itisimportantthatall

thefactsregardingtheproblemaregathered

beforebeginningserviceprocedures.Therst

stepistotalktotheequipmentoperator.Askfor

acompletedescriptionofthemalfunction.The

followingguidelinescanthenbeusedasastarting

pointtobegintroubleshootingprocedures:

Rotate Circuit

• Attachmentwillnotrotate.

• Attachmentwillnotrotatewithloadatrated

capacity.

• Attachmentrotatesinonedirectiononly.

Tocorrectoneoftheseproblems,seeSection3.3.

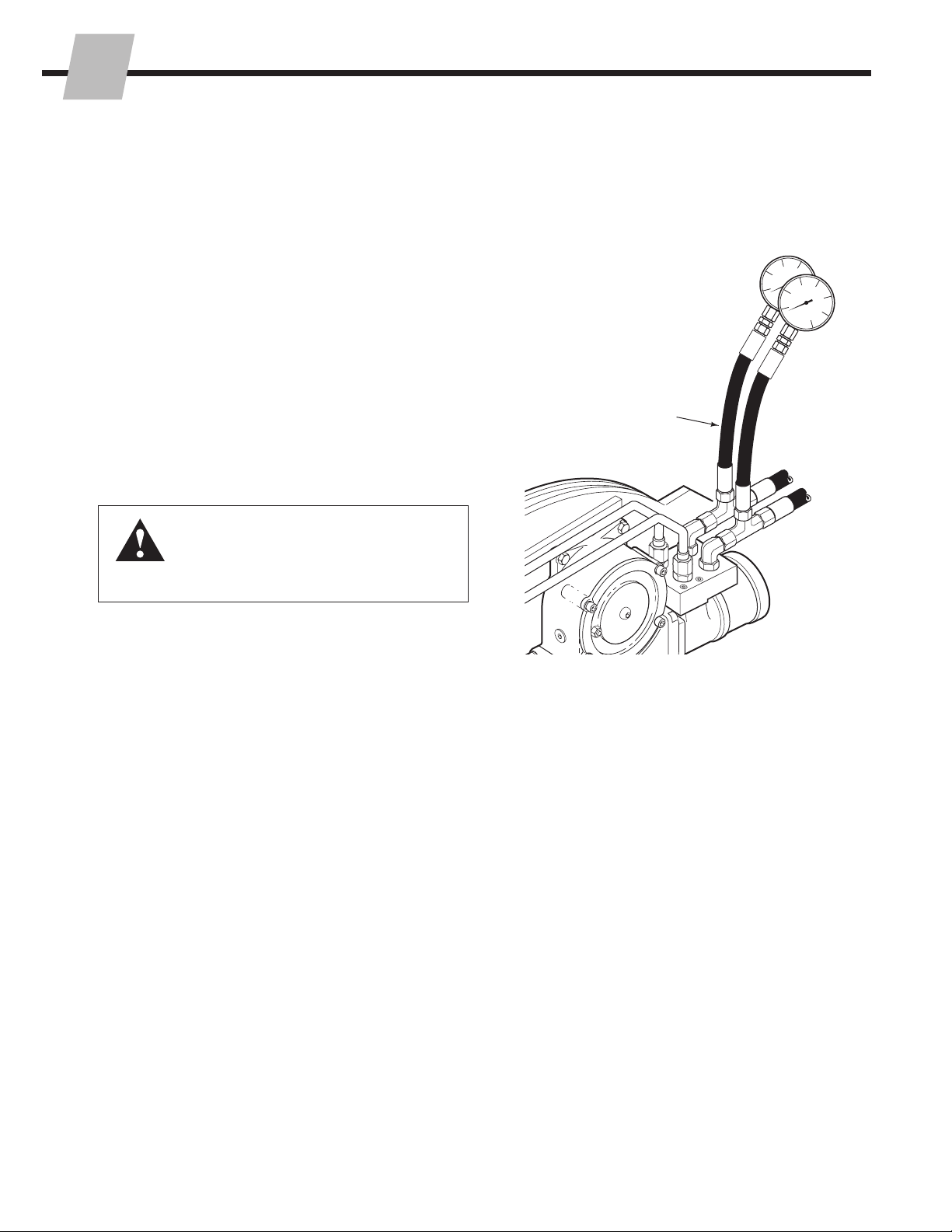

WARNING:Beforeservicinganyhydraulic

component,relievepressureinthesystem.

Turnthetruckoffandmovethetruck

auxiliarycontrolvalvesseveraltimesin

bothdirections.

Aftercompletinganyserviceprocedure,testthe

attachmentthroughseveralcycles.Firsttestthe

attachmentemptytobleedanyairtrappedinthe

systemtothetrucktank.Thentesttheattachmentwith

aloadtobesureitoperatescorrectlybeforereturning

tothejob.

Stayclearoftheloadwhiletesting.Donotraisethe

loadmorethan4in.(10cm)offtheoorwhiletesting.

GA0014.eps

Flow Meter Kit 671477

Pressure Gauge Kit 671212

(2)No.8-12

JIC/O-Ring FlowMeter

(2)No.6-8JICReducer

Pressure

Gauge No.6-6Hose

No.6andNo.8

JICSwivelTee

No.4-6Pipe/JIC No.6-8JIC

Reducer

No.4,No.6

andNo.8

JIC/O-Ring