ONTENTS

C

i

Page

INTRODUCTION, Section 1

Introduction, 1.1 1

Special Definitions, 1.2 1

INSTALLATION, Section 2

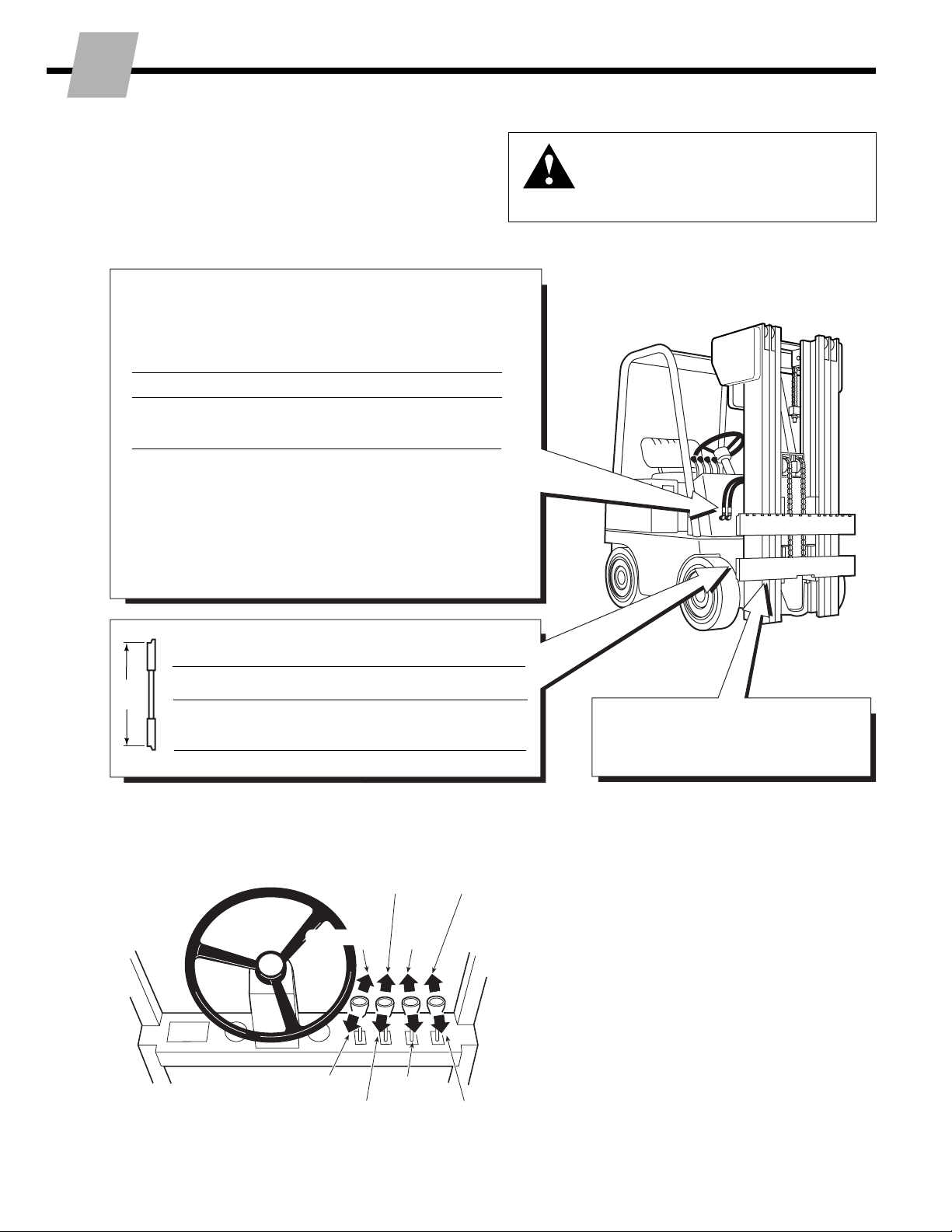

Truck System Requirements, 2.1 2

Recommended Hydraulic Supply Options, 2.2 3

Revolving Clamp Installation Procedure, 2.3 4

PERIOD MAINTENANCE, Section 3

100-Hour Maintenance, 3.1 10

500-Hour Maintenance, 3.2 10

1000-Hour Maintenance, 3.3 10

TROUBLESHOOTING, Section 4

General Procedures, 4.1 11

Truck System Requirements, 4.1-1 11

Tools Required (metric), 4.1-2 11

Troubleshooting Chart, 4.1-3 11

Plumbing, 4.2 12

Hosing Diagram, 4.2-1 12

Hydraulic Circuit, 4.2-2 13

Clamp Function, 4.3 14

Supply Circuit Test, 4.3-1 14

Clamp Circuit Test, 4.3-2 14

Rotate Function, 4.4 15

Supply Circuit Test, 4.4-1 15

Rotate Circuit Test, 4.4-2 16

Electrical Circuit, 4.5 17

SERVICE, Section 5

Revolving Clamp Removal, 5.1 18

Arms, 5.2 19

Arm Assemblies – Removal and Installation, 5.2-1 19

Drum Arm Pad Surface Replacement, 5.2-2 20

Rigid Arm Pad Replacement/Rotation, 5.2-3 21

Clamps without Arms, 5.2-4 22

Arm Bearings – Removal and Installation, 5.2-5 23

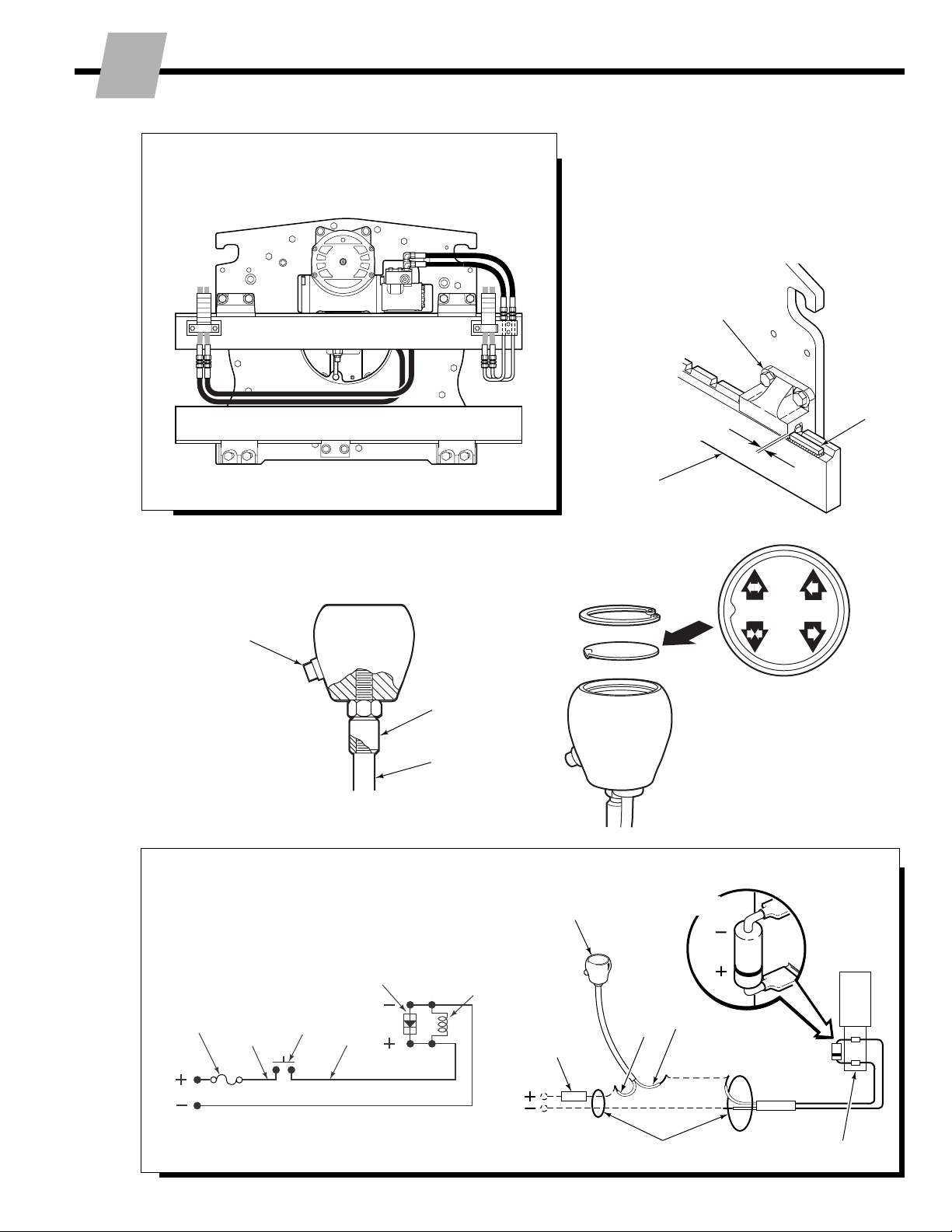

Drive Group, 5.3 24

Drive Group Removal and Installation, 5.3-1 24

Drive Group Disassembly and Service, 5.3-2 24

Drive Group Reassembly, 5.3-3 26

Drive Motor, 5.4 28

Drive Motor Removal and Installation, 5.4-1 28

Drive Motor Disassembly, 5.4-2 29

Drive Motor Inspection, 5.4-3 30

Drive Motor Reassembly, 5.4-4 30

Drive Check Valve, 5.5 32

Check Valve Service, 5.5-1 32

Revolving Connection/Manifold, 5.6 33

Rev.Conn. Removal and Installation, 5.6-1 33

Manifold Removal and Installation, 5.6-2 33

Rev.Conn. Service, 5.6-3 35

Relief Valve Adjustment, 5.6-4 37

Cylinders, 5.7 38

Cylinder Service, 5.7-1 38

Cylinder Disassembly, 5.7-2 38

Cylinder Inspection, 5.7-3 39

Cylinder Reassembly, 5.7-4 40

Cylinder Replacement, 5.7-5 42

Base Unit, 5.8 43

Rotation Bearing Removal and Installation, 5.8-1 43

180-Degree Stop Group, 5.9 45

Stop Valve Adjustment, 5.9-1 45

Stop Valve Service, 5.9-2 46

Solenoid Valve, 5.10 46

Coil Service, 5.10-1 46

Valve Service, 5.10-2 46

SPECIFICATIONS, Section 6

Specifications, 6.1 47

Hydraulics, 6.1-1 47

Auxiliary Valve Functions, 6.1-2 47

Truck Carriage, 6.1-3 47

Torque Values, 6.1-4 48

Page