ERIODIC MAINTENANCE

P

2 6851096

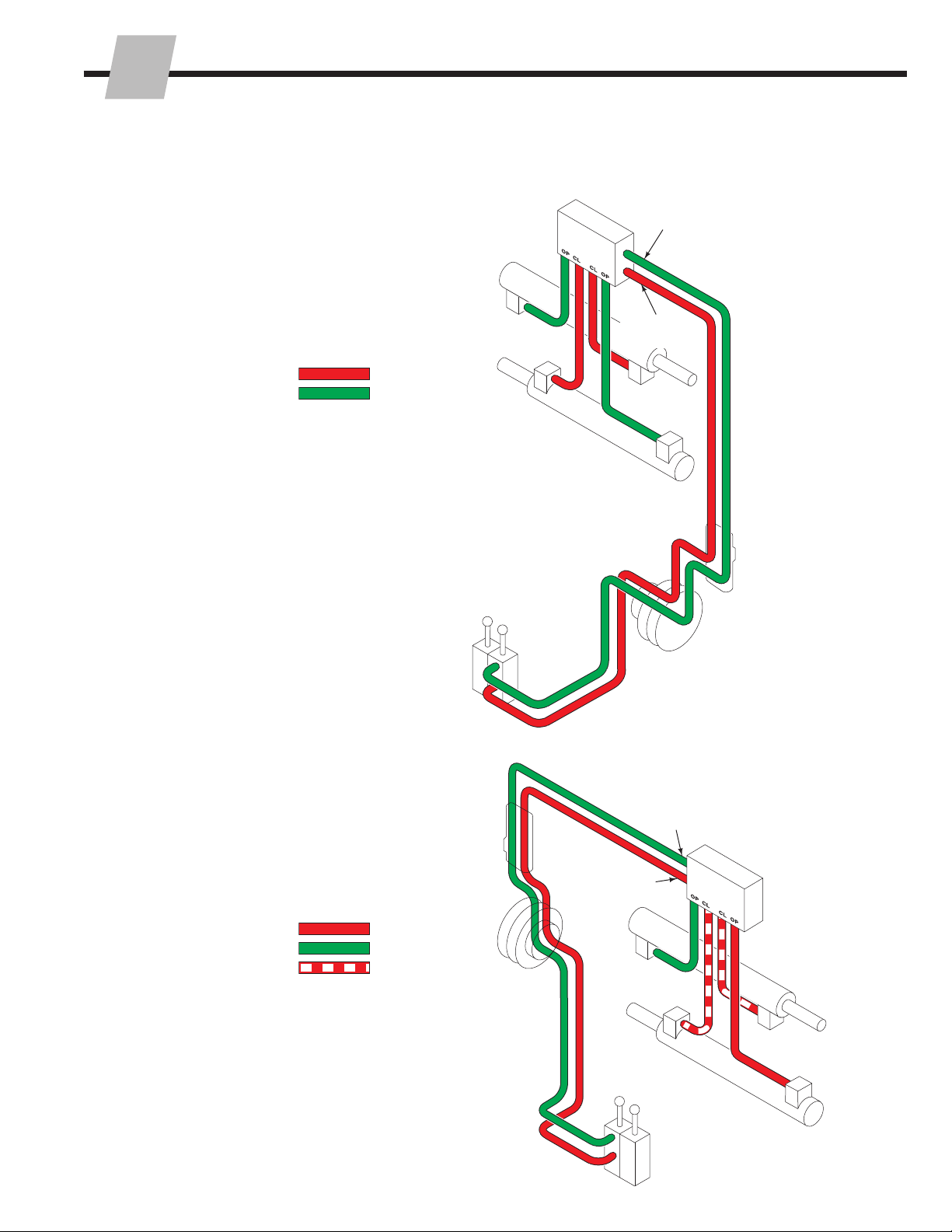

RC4283.eps

WARNING: After completing any service

procedure, always test the attachment

through five complete cycles. First test

empty, then test with load to make sure

attachment operates correctly before

returning it to the job.

2.1 100-Hour Maintenance

Every time the lift truck is serviced or every 100 hours

of truck operation, whichever comes first, complete

the following maintenance procedure:

• Check for loose or missing bolts, worn or damaged

supply hoses and hydraulic leaks.

• Check decals and nameplate for legibility.

• Inspect the cylinder rod anchor joint for lubrication

and correct hold.

NOTE: Anchor joint operates with a loose

clearance. Lubricate with wheel bearing grease.

• Check for equal arm movement.

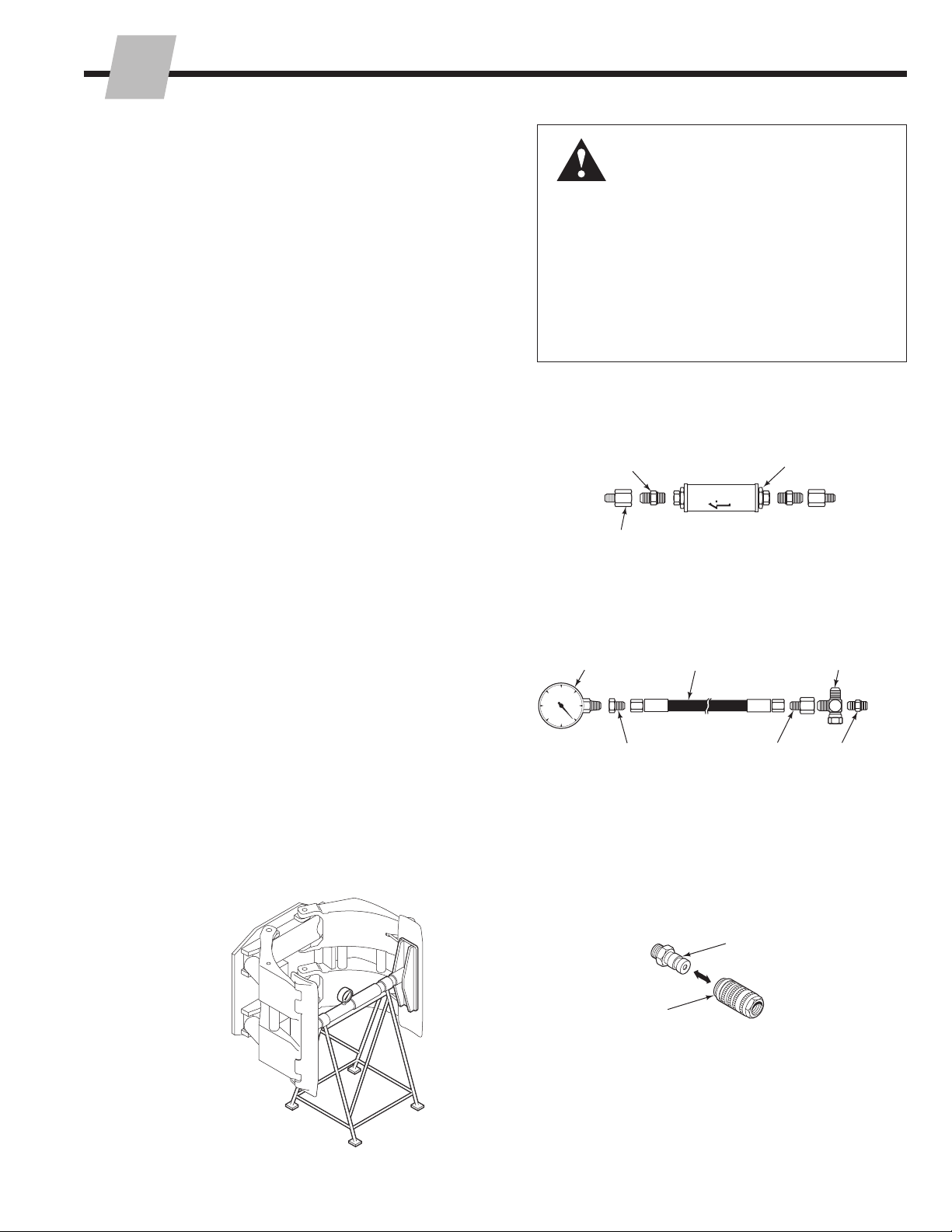

• Check the load holding hydraulic system for

proper function. Cascade Clamp Force Indicators

300G-CFI-812C and 300G-CFI-824C are available

for this test.

2.2 500-Hour Maintenance

After each 500 hours of truck operation, in addition

to the 100-hour maintenance, perform the following

procedures:

• Check the lower mounting hook engagement

clearance with the truck carriage bar:

Quick-Change Hooks – 3/32 in. (2.5 mm) min.

3/16 in. (5.0 mm) max.

Bolt-On Hooks – Tight against lower carriage

bar.

If adjustment is necessary, refer to Section 4.1,

Step 3. Tighten the lower hook capscrews to a

torque of:

CL III – 120 ft.-lbs. (165 Nm)

CL IV – 320 ft.-lbs. (435 Nm)

• Tighten the upper hook capscrews to a torque of

320 ft.-lbs. (435 Nm).

• Inspect all load-bearing structural welds on arms,

frame and cylinder anchor areas for visual cracks.

Replace components as required.

• Inspect contact pads, pivot pins, wear tiles and

arm tips for wear and damage. Replace or repair,

as needed.

2.3 1000-Hour Maintenance

After each 1000 hours to lift truck operation, in

addition to the 100 and 500-hour maintenance

procedures, perform the following procedures.

• Inspect the arm bearings for wear. If any bearing

is worn to less than 0.04 in. (1.0 mm) thickness,

replace all bearings.

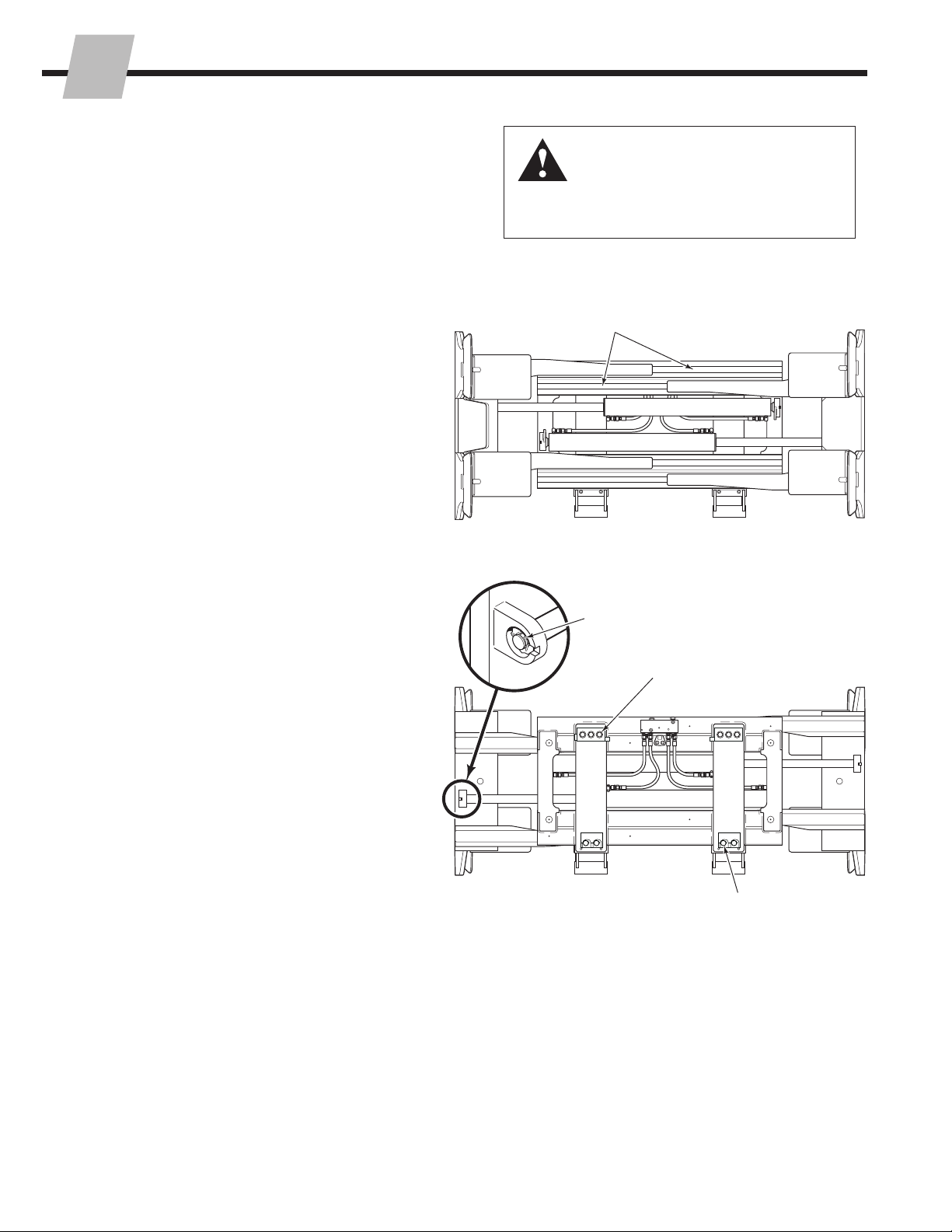

Arm Bearings

Cylinder Anchor Joint

Hook Capscrews

Lower Hook Capscrews

Front View

Back (Driver's) View

2.4 4000-Hour Maintenance

After each 4000 hours of truck operation, in addition to

the 100, 500 and 2000-hour maintenance, perform the

following procedures:

• Due to normal mechanical wear and component

service life, cylinder seals should be replaced to

maintain performance and safe operation.