tornos EvoDECO 10/10 User manual

EvoDECO 10/10 & 10/8

INSTRUCTION MANUAL

ENGLISH VERSION TRANSLATED FROM THE ORIGINAL VERSION

TORNOS SA CH-2740 MOUTIER

http://www.tornos.ch

Ref. : 298061_fr – Printed in Switzerland - Copyright © 1999-2012

Attention!

Read this precautions before,

all users must read the instruction manual and pay

particular attention to the "SAFETY INSTRUCTIONS" !

Keep this document for future reference.

Instruction Manual - EvoDECO 10/10 & 10/8

298061_en - 07/12

I. Identification

I.1. Document

Instruction Manual EvoDECO 10/10 & 10/8

No 298061_en

Version manager

Version Date Description

06/12 01/06/2012 First edition

298061_en - 07/12

Instruction Manual - EvoDECO 10/10 & 10/8

I.2. Manufacturer

TORNOS SA

Rue Industrielle 111

CH-2740 MOUTIER / SWITZERLAND

Tel. +41 (0)32 494 44 44

Fax +41 (0)32 494 49 03

www.tornos.ch

I.3. Products

EvoDECO 10/10 & 10/8

Instruction Manual - EvoDECO 10/10 & 10/8

298061_en - 07/12

Source suvaPro

Behaviour in the event of an emergency

1. Keep calm

2. Think

3. Act Raise the alarm Ambulance

Police

Fire brigade

Poisoning

Doctor

Hospital

Who? Person raising the alarm.

What? What happened?

Where? Place, street, number, access, floor, etc.

How many? Number of people involved.

Other Particular dangers, dangerous materials, etc.

Accident 1. Secure the dangerous area.

2. Raise the alarm.

3. Give first aid.

4. Inform ambulance staff.

Position(s) of first aid box:

Fire 1. Notify the fire brigade.

2. Find shelter for yourself and others.

3. Close window(s) and door(s).

4. Inform the fire brigade staff.

5. Put the fire out.

Evacuation 1. Notify the people in danger and evacuate them.

2. Leave the premises using the stairs.

3. Go to the assembly point.

Assembly point(s):

Person in charge of keeping the emergency numbers, first aid boxes and training

up-to-date:

Mandatory!

Apply the regulations in force in your company. If there are no regulations, you can adapt the

above example to your country’s legislation and to the specific needs of your company.

298061_en - 07/12

Instruction Manual - EvoDECO 10/10 & 10/8

Instruction Manual - EvoDECO 10/10 & 10/8

298061_en - 07/12

TABLE OF CONTENTS

1 Installation conditions.............................................................................. 1-1

1.1 Machine identification....................................................................................1-1

1.2 Machine dimensions.......................................................................................1-2

1.2.1 Dimension specifications....................................................................................... 1-2

1.2.1.1 Dimensions EvoDECO 10/10 & 10/8 ................................................................................1-2

1.2.1.2 Dimensions EvoDECO 10/10 & 10/8 with bar feeder SBF 216 EVO...............................1-3

1.3 Safety clearance.............................................................................................1-4

1.3.1 Chip tank................................................................................................................. 1-4

1.4 Conditions of use.............................................................................................1-5

1.4.1 Respecting the environment ................................................................................. 1-5

1.4.2 Quality of the floor.................................................................................................. 1-5

1.4.3 Operating environment.......................................................................................... 1-6

1.4.3.1 Temperature and ambient humidity...............................................................................1-6

1.4.3.2 Noise ..................................................................................................................................1-6

1.4.4 Air extraction specifications.................................................................................. 1-7

1.4.4.1 Minimum room volume....................................................................................................1-7

1.4.4.2 Ventilation of premises.....................................................................................................1-7

1.4.4.3 Oil spray and fume extraction.........................................................................................1-8

1.5 Energy supply connection specifications...................................................1-10

1.5.1 Electrical connection........................................................................................... 1-10

1.5.2 Pneumatic connection......................................................................................... 1-10

1.6 Guard opening/closing................................................................................1-11

1.7 Machine connection to the barfeeder .......................................................1-12

1.7.1 Description ............................................................................................................ 1-12

1.7.2 Necessary specifications..................................................................................... 1-12

1.7.3 Capacity and length of the remnant.................................................................. 1-14

1.7.4 Length of the remnant and part for SBF 216....................................................... 1-14

2 Installation................................................................................................. 2-1

2.1 Work environment (specific to the installation) ...........................................2-2

2.1.1 Order and cleanliness............................................................................................ 2-2

2.2 Unpacking........................................................................................................2-4

2.2.1 Removal of the transport flanges.......................................................................... 2-4

2.3 Installation........................................................................................................2-4

2.4 Cleaning...........................................................................................................2-4

2.5 Alignment of the bolt-making machine / bar feeder .................................2-4

2.6 Connecting the energy supplies ...................................................................2-5

2.6.1 Electrical connection ............................................................................................. 2-5

2.6.1.1 Connection to the local mains........................................................................................2-6

2.6.1.2 Connection via an autotransformer................................................................................2-7

2.6.2 Pneumatic connection........................................................................................... 2-8

2.7 Topping up liquids...........................................................................................2-9

2.7.1 Glycerine tank ........................................................................................................ 2-9

2.8 Topping up liquids.........................................................................................2-10

2.8.1 Cutting liquid tank ................................................................................................ 2-10

2.8.2 Centralised lubrication reservoir......................................................................... 2-11

2.8.3 Spindle coolant circuit reservoir ......................................................................... 2-12

298061_en - 07/12

Instruction Manual - EvoDECO 10/10 & 10/8

2.9 Preparation of the machine for movement................................................ 2-13

2.9.1 Disconnecting power sources............................................................................. 2-13

2.9.1.1 Electrical power supply ................................................................................................. 2-13

2.9.1.2 Pneumatic supply........................................................................................................... 2-14

2.9.2 Emptying liquids.................................................................................................... 2-14

2.9.2.1 Cutting liquid................................................................................................................... 2-14

2.9.2.2 Spindle coolant............................................................................................................... 2-14

2.9.2.3 Greasing liquid ............................................................................................................... 2-14

2.9.2.4 Machine cleaning.......................................................................................................... 2-14

2.10 Moving the machine .................................................................................... 2-15

2.10.1 Machine maintenance ........................................................................................ 2-15

2.10.2 Lifting the machine............................................................................................... 2-16

Instruction Manual - EvoDECO 10/10 & 10/8 - 1. Installation conditions

298061_en - 07/12 1-1

1. Installation conditions

For unpacking and moving the machine, see the document Transportation sheet.

1.1. Machine identification

The warning plate contains the following information:

Fig. 1

Location of parts

Marker lines Function

(1) Machine type

(2) Serial number

(3) Machine identification number

(4) Year of manufacture

Mandatory!

The serial number must be quoted for all contacts with TORNOS SA departments.

(1)

(2)

(3)

(4)

298061_en - 07/12

1. Installation conditions - Instruction Manual - EvoDECO 10/10 & 10/8

1-2

1.2. Machine dimensions

1.2.1. Dimension specifications

1.2.1.1. Dimensions EvoDECO 10/10 & 10/8

Fig. 2

Name Unit Value

Dimensions

Length m 1.870

Width m 1.140

Width (NC control expanded) m 2.045

Height (without signal lamp) m 1.950

Height (doors and guards open - without signal lamp) m 2.350

Spindle height m 1.100

Weight

Complete machine kg 1650

Instruction Manual - EvoDECO 10/10 & 10/8 - 1. Installation conditions

298061_en - 07/12 1-3

1.2.1.2. Dimensions EvoDECO 10/10 & 10/8 with bar feeder SBF 216 EVO

Fig. 3

298061_en - 07/12

1. Installation conditions - Instruction Manual - EvoDECO 10/10 & 10/8

1-4

1.3. Safety clearance

Fig. 4

1.3.1. Chip tank

Mandatory!

A clearance of at least 1 metre must be left for access all around the machine and the bar

feeder.

This clearance space is reserved and authorised only to those people working on the machine

for production or maintenance purposes.

Specifications

Name Unit Value

Minimum safety clearance all around the machine m 1

Warning !

The clearance space of 1 metre around the machine must consider the length of the chip tank

which is 1.3 metres.

Instruction Manual - EvoDECO 10/10 & 10/8 - 1. Installation conditions

298061_en - 07/12 1-5

1.4. Conditions of use

1.4.1. Respecting the environment

Machine use

- Take the necessary precautions in the plants, so as not to pollute the environment.

- The use of the machine and of the different elements surrounding it must be made in observance

of the environmental regulations in force in the country of installation.

- Production effluent must be disposed of in accordance with the regulations in force in the country

of installation.

- Waste resulting from production must be disposed of in accordance with the regulations in force

in the country of installation.

Scrapping

Scrapping the machine, its components and the elements connected to it must be performed in

observance of the environmental regulations in force in the country of installation.

Special attention must be paid to:

- lubricant oils;

- batteries;

- electronic parts.

which must be handed over to a recycling plant.

Regulations in force

The user should find out more from the relevant authority in the country of installation.

1.4.2. Quality of the floor

Information!

The floor needs to be sufficiently resistant to support the weight of the machine and all its

components. TORNOS SA recommends a non-slip surface. We do not recommend the use of

non-slip mats in other places. This could cause people to trip and fall.

Specifications

Name Unit Value

Quality of the floor - Hard, stable, free

from vibrations

and perfectly

level.

Allowable surface load daN/cm² 12

298061_en - 07/12

1. Installation conditions - Instruction Manual - EvoDECO 10/10 & 10/8

1-6

1.4.3. Operating environment

1.4.3.1. Temperature and ambient humidity

Mise en garde !

Tout appareil s’utilise dans des tolérances n’atteignant pas et ne dépassant pas les limites de ses

caractéristiques de fonctionnement.

1.4.3.2. Noise

The purpose of the noise measurements is to determine the average sound levels where an

operator works most of the time.

The measurements take account of the following:

- a) sound power level;

- b) sound surface pressure level;

- c) Sound pressure level at the operator's workstation.

Avertissement !

Si pour des raisons particulières, la charge sonore au poste de travail (Leq) est de 85 dB (A) ou plus,

l'employeur met à disposition de son personnel des informations utiles sur le bruit, ainsi que des

protecteurs d'ouïe au poste de travail et leur port est recommandé.

Specifications

Name Unit Value

Maximum ambient humidity % 79

Ambient temperature of the workplace °C 5 - 35

Relative temperature °C +/- 15

Note!

The parameters which influence the real exposure levels include the duration of the operator's

exposure to noise, the shop characteristics, the other sources of noise, etc.

The values measured in the given conditions are those of the actual emission levels and make no

claim to conform to the safety-at-work levels.

Even though correlations between the noise emission and exposure levels exist, this noise

measurement report cannot serve as a basis for determining whether additional precautions are

required.

Any measurement results obtained on a particular production site, will obviously differ from those

measured by TORNOS SA at its plants.

Instruction Manual - EvoDECO 10/10 & 10/8 - 1. Installation conditions

298061_en - 07/12 1-7

1.4.4. Air extraction specifications

1.4.4.1. Minimum room volume

1.4.4.2. Ventilation of premises

Information!

According to DIN 14497, the minimum room volume per machine must be 10m3 per kilogram of

CO2in order to allow use of the fire-fighting equipment (reference 5483).

Warning !

If the room volume is too small, there is a risk of death from asphyxiation when using the fire-

fighting equipment.

Minimum shop volume per machine

Name Unit Value

EvoDECO 10/10 & 10/8 DCS-PTO m3100

Information!

The premises where the machine is installed must be adequately ventilated.

Mandatory!

Observe the regulations in force in the country of installation.

298061_en - 07/12

1. Installation conditions - Instruction Manual - EvoDECO 10/10 & 10/8

1-8

1.4.4.3. Oil spray and fume extraction

Fig. 5

Mise en garde !

Assurez-vous du bon fonctionnement des ventilateurs ainsi que de leur nettoyage périodique

(grilles, filtres). Prêtez une attention particulière aux ventilateurs des moteurs dans la zone

d'usinage.

CHARACTERISTICS OF OIL SPRAY EXTRACTION

Machine type Unit Value

EvoDECO 10/10 & 10/8

minimum suction Ø [mm] mm 100

Machining area volume m³ 1

Extraction rate m³/h 500

Danger!

Based on the type of machining applied to the machine, the release of vapour and fumes may

be significant. It is highly recommended in all cases, to install a fume and oil spray extraction

system.

All TORNOS SA machines are equipped with a connection for a fume and vapour extractor or

collector.

Warning !

Despite installation of the fume discharger, the treatment system may be insufficient during heavy

release of fumes.

Mandatory!

During installation of a fume or vapour collector or extractor, the fitting diameter must not be

modified for any reason (constriction or plugging forbidden).

Scrupulously comply with the technical specifications and instructions; siphoning effect to forbid

= accumulation of condensate.

Warning !

The filter must be able to operate constantly while the machine is on. It must not be connected so

that it operates according to the machine cycles or intermittently.

Instruction Manual - EvoDECO 10/10 & 10/8 - 1. Installation conditions

298061_en - 07/12 1-9

Warning !

The entire oil spray extraction system or fume filter (options 5436 or 5438) must be equipped with

a shut-down system compatible with the fire-fighting device (centralised suction check valve or

suction motor brake fitted on the machine, controlled by the emergency stop or fire-fighting

system, this is under the responsibility of and at the expense of the buyer).

Danger!

Make sure the motor rotates in the right direction. Check the rotating field.

Attention!

Make sure the device is at a complete standstill and disconnected from the electricity supply

before opening the cover.

298061_en - 07/12

1. Installation conditions - Instruction Manual - EvoDECO 10/10 & 10/8

1-10

1.5. Energy supply connection specifications

1.5.1. Electrical connection

1.5.2. Pneumatic connection

Name Unit Value

Electric power kVA 10

Protection fuse against intensity overloads A 20

Power supply voltage VAC 400

Power supply tolerance % +/- 5

Power supply frequency Hz 50

Mandatory!

The machine must be supplied with dry air and without oil.

If the air of your network contains oil or condensate it is necessary to install an air dryer at the

circuit inlet to avoid malfunctioning or breakdowns of the machine.

Quality according to ISO 8573-1

Name Unit Value

Operating pressure bar 6

Average consumption of 6 bar system (max) m3/h 20

Flow rate l/min 100

Quality class, shop standard - 4

Maximum particle size µm 15

Mass concentration mg/m38

Maximum pressurised dew point °C + 3

Maximum concentration in oil mg/m35

Fast connection - G 1/4"

Instruction Manual - EvoDECO 10/10 & 10/8 - 1. Installation conditions

298061_en - 07/12 1-11

1.6. Guard opening/closing

Fig. 6

Danger!

Only a qualified person is authorised to work inside the electrical cabinets or on electrical parts.

Description of parts

Rep. Function Operator

access Maintenance

access

(1) Mechanical part lateral access guard lock X X

(2) Chip tank access guard lock X X

(3) Electrical cabinet rear guard lock X

(4) Mechanical part rear access guard lock X

124

3

298061_en - 07/12

1. Installation conditions - Instruction Manual - EvoDECO 10/10 & 10/8

1-12

1.7. Machine connection to the barfeeder

1.7.1. Description

The machine is always equipped with a bar guide (tube or barfeeder with push-rod).

The bar guide must be an independent machine unit with its own control. The control panel will be

positioned so that the manual bar guide controls are adapted to the machine.

1.7.2. Necessary specifications

- If possible machine bars with a diameter of Ø 1 to Ø 10 mm.

- The maximum rotation speed must be 14000 min-1 (left / right).

- The position of the end of bar sensor is set when the "MACHINE / BAR GUIDE" unit is installed, this

position cannot be changed, no matter what the length of the parts to be machined.

- When the position or the end of bar sensor is enabled, the push rod must still be able to make a

stroke of at least 300 mm.

-Foratube:

No preparation of the bar should be necessary to cover the entire range of capacity.

- For a barfeeder:

No preparation of the bar should be necessary for bars with a diameter of Ø 1 to Ø 10 mm, and

remnant extraction should be from the back. When changing the bar, it is necessary to be able to

perform a "calibration" of it to position it a few mm outside the guidebush before the cut off in

order to avoid having to press against the cutting tool (shock).

Warning!

The space between the machine and the barfeeder must not allow a hand to pass, in order to

prevent any risk of accidents.

Warning !

An interface, defined by TORNOS SA, describes the functions that need to be performed by the

bar guide. This must be strictly complied with, in order to ensure perfect operation of the

"BARFEEDER - MACHINE" combination (poor operation of the barfeeding machine risks being

attributed to the machine).

The manufacturer of the bar guide is fully liable for its equipment in terms of current regulations in

the various countries and damage or accident where the cause is due to the bar guide.

This manual suits for next models

1

Table of contents

Other tornos Lathe manuals

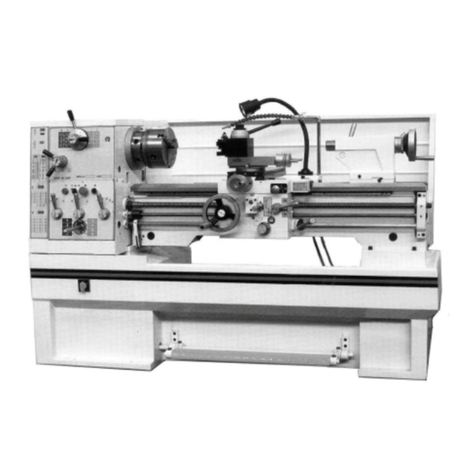

Popular Lathe manuals by other brands

TRAK

TRAK TRL 1630HSRX Safety, installation, maintenance, service & parts list manual

Jet

Jet GH-1640ZK Operation and maintenance instructions

ADENDORFF

ADENDORFF ELATHE-140 Instruction manual & parts list

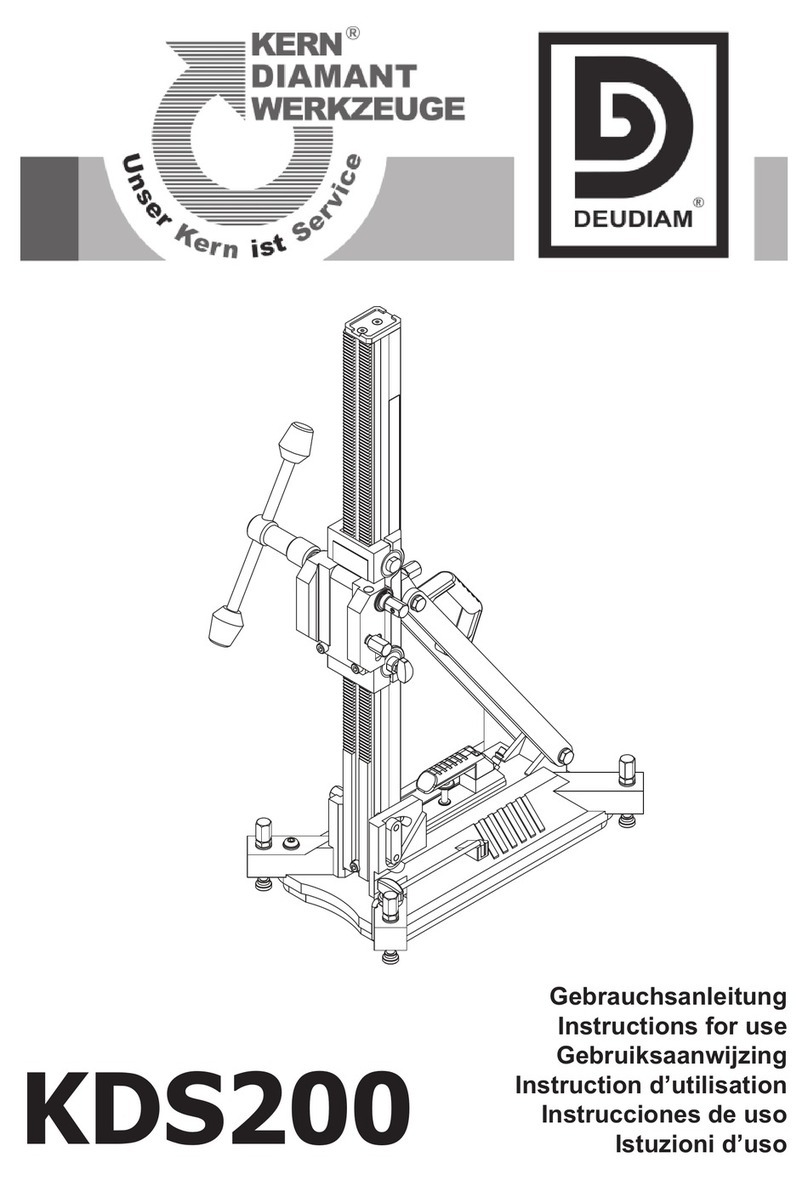

KERN

KERN KDS200 Instructions for use

Jet

Jet BDB-1340A owner's manual

WoodFast

WoodFast M910 instruction manual