1

INTRODUCTION

You have just purchased a CS 88 / CS 89. We congratulate you on your excellent choice

and we thank you for your trust.

The CS 88 / CS89 benefits from our long of experience in manufacturing frame assembly

machines which have made us famous. It will assemble wooden mouIdings of any profile (Pa-

tent n’8800188).

The CS 88 / CS89 is designed to permit operators to work in front of the machine or behind it.

Assembly is by metal wedges designed specially to ensure perfect joining.

Use only wedges in cartridges manufactured by CASSESE® (CS trademark).

Beware of copies.

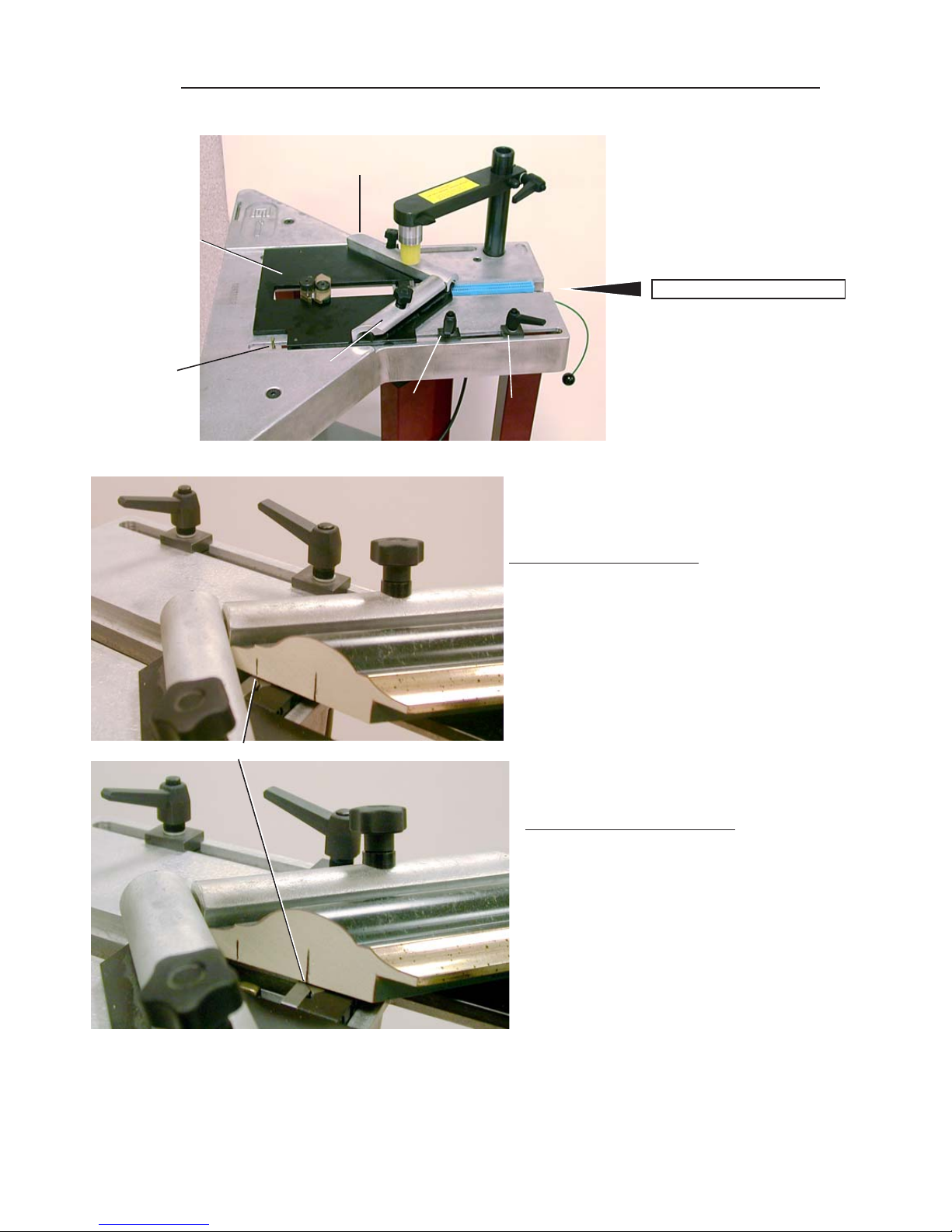

ACCESSORIES supplied with the rnachine:

- 3 allen wrenches ( 2.5 - 3 - 6 ),

- 1 replacement hammer,

- 1 white triangle (for soft woods),

- 1 black triangle for hard woods (mounted on machine)

and its aluminium support,

- 1 tool for removing wedges from distribution head,

- 1 tube of grease

- 1 Spacer bars for small mouldings.

+(CS 89 only) 1 round rubber top presser (yellow for soft woods) + its aluminium

support

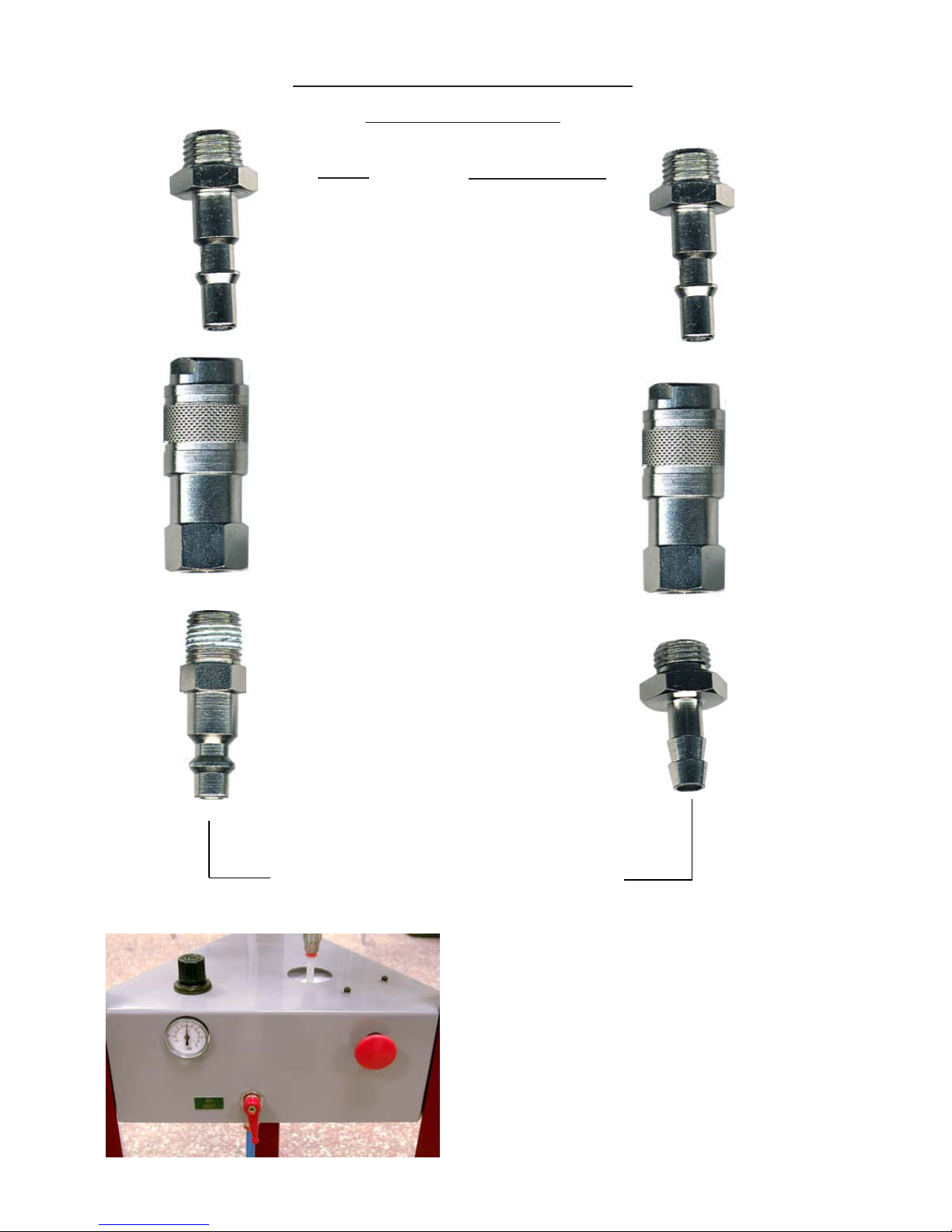

+(CS 89 only) air supply fittings : 1 male connector (on machine) + 1 quick release

female connector + 2 (1 standard + 1 US) hose connectors.

SPECIFICATlONS :

Minimum width of moulding : 5 mm maximum: 95 mm

Minimum height of moulding : 5 mm maximum: 85 mm

Minimum size of frame : 60 x 60 mm (opening) -

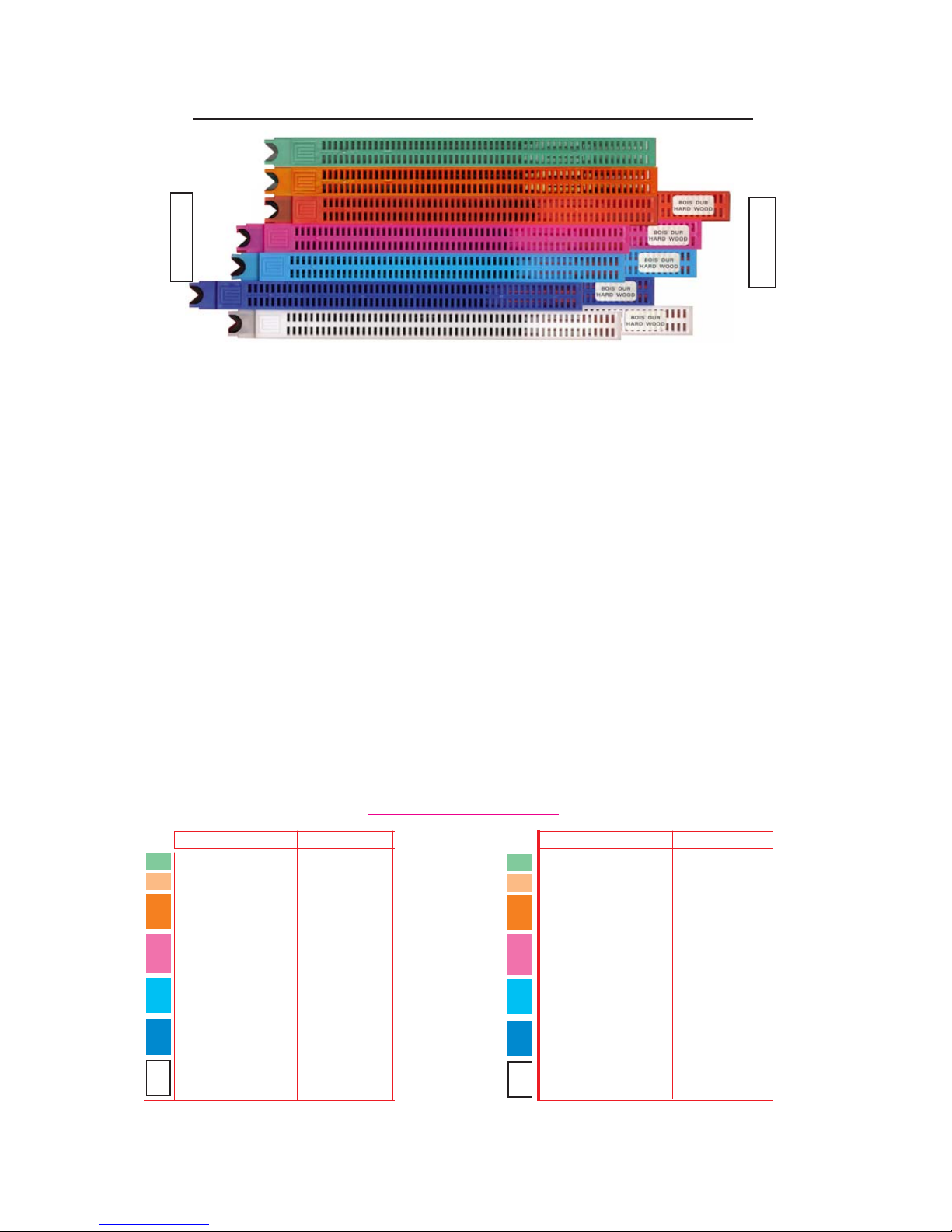

Size of wedges in cartridges of 275 : 3, 4, 5, 7, 10, 12, 15mm

Two types of wedges for : soft wood, hard wood.

Net weight : 25 kg

Dimensions : Width: 600 mm (24’’) Depth: 450 mm (18’’)

Height: 1090 mm (431/2’’)

( CS 89 only) Energy needed : Compressed air 6-7 bars (+/- 100 p.s.i.)

(CS 89 only) air supply : air regulator + manometer, air tube to be used

(inside diameter 8mm) for the standard connector.

OPTIONS

Octogonal, hexagonal inserts or other to order. Other top pressers.

- 3 sockets to attach the machine to the floor:

Insert the part D of the sockets into the holes of the feet

and then fix the sockets to the floor with a screw (not supplied).

WARRANTY

CS 88 / CS89 is covered by a one year warranty for parts and labour and any manufacturing

defects. Worn parts and parts damaged by use not in conformity with the terms of this manual

are not covered by this warranty.

FIXING

SCREW

D