2

Instructions for use of the tyre assembly system.

INDEX

1. Introduction ...............................................................................................................................2

2. General safety rules................................................................................................................. 33

.................................................................................................................................................... 3

3. Technical data......................................................................................................................... 33

.................................................................................................................................................... 3

4. Transport................................................................................................................................ 34

.................................................................................................................................................... 3

5. Rozpakowywanie ..................................................................................................................... 44

.................................................................................................................................................... 4

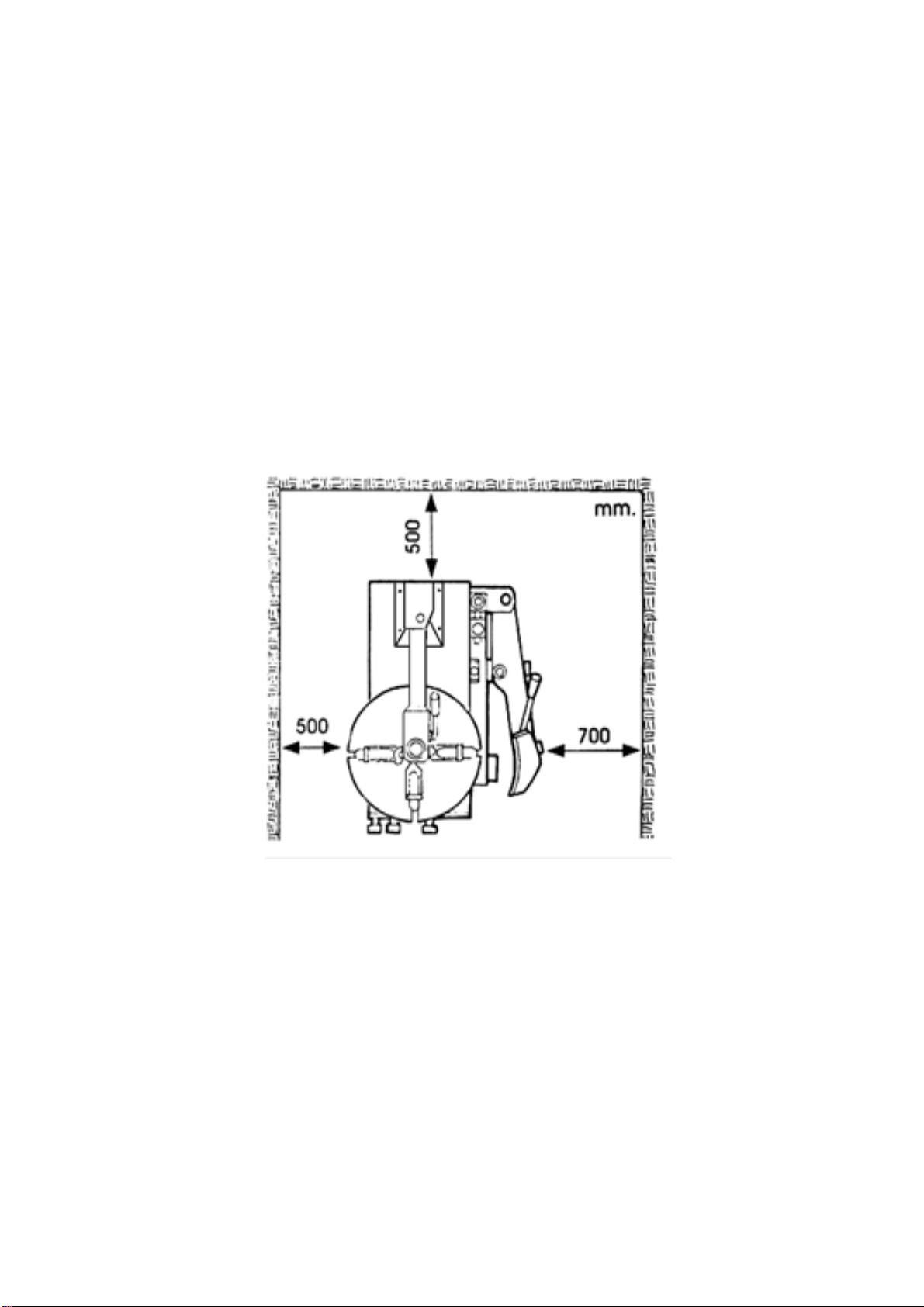

6. Workplace............................................................................................................................... 44

.................................................................................................................................................... 4

8. Installation method.................................................................................................................. 66

.................................................................................................................................................... 6

9. Pneumatic connector: .............................................................................................................. 66

.................................................................................................................................................... 6

10. Electrical connector................................................................................................................ 67

.................................................................................................................................................... 6

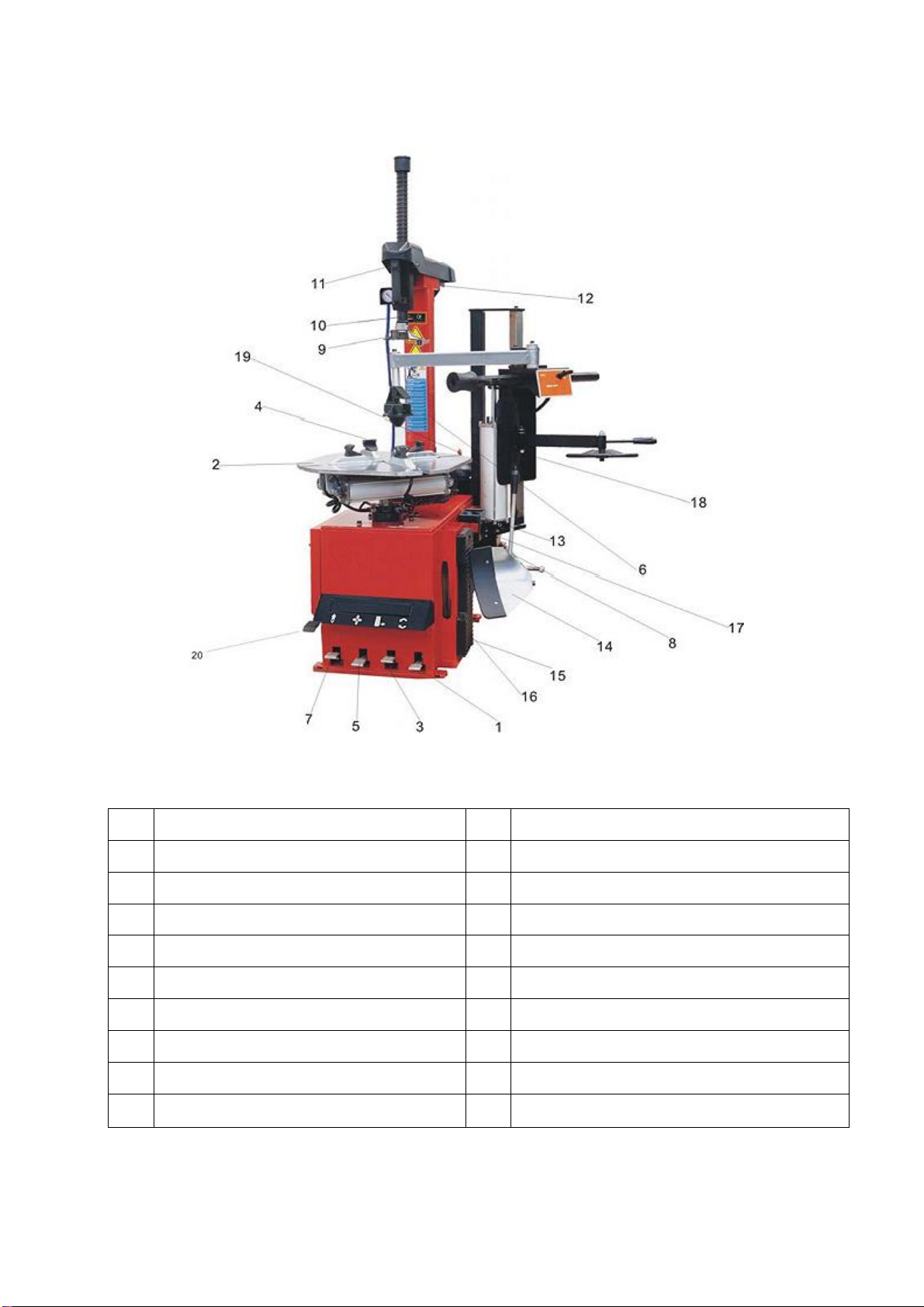

11. How the device is used. ........................................................................................................ 77

.................................................................................................................................................... 7

12. Preparing for use. ................................................................................................................. 77

.................................................................................................................................................... 7

13. Instructions for use................................................................................................................ 78

.................................................................................................................................................... 7

13.1 Loosening the tyre edging ................................................................................................ 88

................................................................................................................................................ 8

13.2 Tire....................................................................................................................8crimping 8

................................................................................................................................................ 8

13.3 Removing the tyre ........................................................................................................... 89

................................................................................................................................................ 8

13.4 Tyre assembly ..................................................................................................................... 99

.................................................................................................................................................... 9

13.4.1 Checking the tyre and wheel rims. Fig. 9 ..........................................................................

99.......................................................................

9

13.4.2 Tyre assembly .............................................................................................................910

................................................................................................................................................ 9

13.5. Pumping a threadless wheel (without the use of a special device for pumping heatless tyres)

...............................................................................................................................................1010

.................................................................................................................................................. 10

13.6 Pumping of driverless tyres (using a device for this type of tyre) .........................................1011

.................................................................................................................................................. 10

14. Storage..............................................................................................................................1112

.................................................................................................................................................. 11

15. Maintenance.......................................................................................................................1113

.................................................................................................................................................. 11