NHProEquip TC-1300 User manual

3456789

目

录

C61CN

1

目

Content

1. Introduction .........................................................................................

2.General infomation ...............................................................................

3.Transportation,unpacking and storage ..................................................

4.Installation ............................................................................................

5.Operation ..............................................................................................

6.Inflation.................................................................................................

7.Installation and operation of the helper ...............................................

8.Maintenance .........................................................................................

9.Troubleshooting ....................................................................................

10. Electrical and pneumatic scheme

Symbol and code printed

In the manual, the following symbol and code is convenient for reading

Need careful operation

Prohibition

May cause the danger to the operator

Bold

Important information

Warning:Before lift and any operation, carefully read the

chapter 7 “Installation”in which it is the description of

the proper operation for the better lift.

2

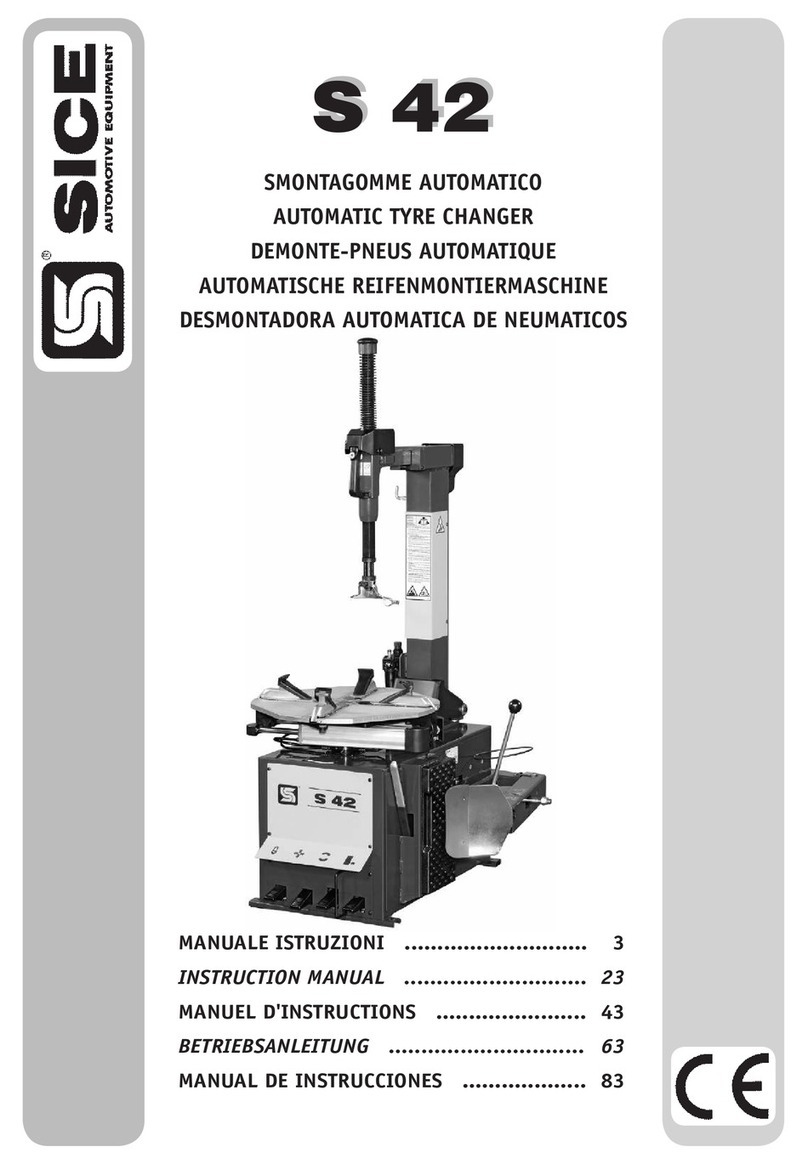

Main operation part(as Fig1)

1. Introduction

1.1 Introduction

The product is based on the principle of the best. Following

the simple instruction in the manual can guarantee the

correct operation and prolong the service life of the machine.

Read thoroughly the instruction manual and make sure that

you understand it correctly.

1.2 Nameplate of the tire changer

The full description of the model and series number will

help our technical assist department to provide the service

easier and also it is convenient to deliver the spare parts. For

your convenience, we will add the data of the tire changer

into the following frame. If the data in the manual is

different from the data on the nameplate, we will consider

the data attached on the machine to be the correct one.

1.3 Remain of the manual

To correctly use this manual, we propose the following

suggestions:

Keep the manual at the place easy to take;

Keep the manual at the moisture-proof place;

Properly use the manual and do not damage it;

The operator must be familiar with the instruction and

procedure of the manual.

This manual is integrated with the products. When the

machine is resold, the manual must be provided to the new

owner.

!

The parts and components on the photo may be

different from the actual ones.

1.4General security measure

2. General information

2.1Purpose

This tire changer is special designed and manufactured for

mounting and demounting rim.

Herewith,the manufacturer will not be responsible for the

damage arising from the operations improper, incorrect

and unreasonable.

2.2Instruction

Tire changer can only be operated by the

professional person under special training.

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

R

Q

T

U

3

Fig2-1

A. vertical shaft spring

B. handle valve lock button

C. hexangular shaft

D. tool head

E. clamping jaw

F. turntable

G. pedal assembly decal

H. column tilting pedal

I. clamping pedal

J. bead breaking pedal

K. turntable rotation pedal

L. crowbar inserting hole

M. wheel supporting rubber

N. bead breaker blade

O. bead breaker blade handle

P. bead breaker arm

Q. clamping cylinder

R. bead breaker cylinder

T. air tank

U. column

V. inflation gauge container

W. horizontal arm

X. lock cylinder

2.3warning decal

Electrical shock!

Do not reach any part of your body

under the tool head.

When breaking bead, the bead

breaking blade will quickly move

leftwards. The operator should not

stand between the blade and tire.

Note: when break the bead, the

opened clamp cylinder may

injury the hand of the operator.

Remember, do not touch the side

wall of the tire.

When clamping the rim, do not

reach your hand or other parts of

the body in between the clamp &

the rim.

Do not stand behind the column

to avoid the column from injuring

the persons when swing.

Wear gloves.

Read the user manual.

Wear goggles.

During maintenance, switch

off the power supply.

Keep hand

away from

tire during

operation

Before use,

carefully read

the manual.

When

operation,

wear

protection.

4

Security position indication

Pay attention to keep the safety labels complete.

When it is not clear of missing, you should change

the new label.

You should let the operators see the safety labels

clearly and understand the meaning of the label.

Fig 2-2

2.4Technical specification(standard configuration):

Outside clamping size(inch)

15-20

Inside clamping size(inch)

15-24

Max. tire size(inch)

24(610mm)

Max. tire wide(inch)

12(305mm)

Bead breaking force(10bar)

2500kg

Work pressure

10bar(145psi)

Max. inflation pressure

3.5bar(50psi)

Electric supply voltage

220V/380V230V/400V 3PH

110V 220V 230V 1PH

Motor power

0.75(3phase, single speed)

0.85/1.1kw(3phase dual speed)

1.1kw(single phase)

Rotation speed

7-14rpm

Max. spindle torque

1200Nm

Package size

1400×880×980

Net weight

243kg STND 310kg G

Noise under work condition

﹤70dB(A)

temperature

-5℃~45℃

R.H

30%~95%

altitude

Max. 1000M

Technical specification(standard configuration):

Different due to the size of the turntable

Outside clamping size(inch)

15-24

Inside clamping size(inch)

15-26

Max. tire size(inch)

26(610mm)

Max. tire wide(inch)

15(305mm)

Bead breaking force(10bar)

2500kg

Work pressure

10bar(145psi)

Max. inflation pressure

3.5bar(50psi)

Electric supply voltage

220V/380V230V/400V 3PH

110V 220V 230V 1PH

Motor power

0.75KW(3phase , single speed)

5

0.85/1.1kw(3phase dual speed)

1.1kw(single phase)

Rotation speed

7-14rpm

Max. spindle torque

1200NM

Package size

1480×1050×1050

Net weight

387kg STND 430kg GT

Noise under work condition

﹤70dB(A)

temperature

-5℃~45℃

R.H

30%~95%

altitude

Max. 1000M

3. Transportation, unpacking &

storage

3.1 Transportation

The transportation should apply the original package.

The tire changer packed should be carried by the forklift

with the proper load. Insert the fork as per the position

indicated(Fig3.1).

Fig3-1

3.2 Unpacking

Remove the cupboard and nylon bag used for protection.

Check whether the equipment is perfect to endure the parts

are not missing and without any damage.

If you have any question, do not use the

machine, contact the dealer.

3.3 Storage

If you need long term of storage, you should ensure the

switching off of the power supply and lubricate the clamping

The tire changer with the motor should not be used

in the environment with the danger of explosion.

IT

Standard:Kg.

GT: Kg

IT

Standard:Kg.

GT: Kg

6

jaw guide rail on the turntable to prevent the oxidization.

4. Installation

4.1Space requirement

When choose the installation site, you should make

sure it meets the forced safety work regulation.

The tire changer must be connected with the power supply

and air supply. Hence, we suggest to install the tire changer

near the power supply and air supply for the convenience

of correct use of all the parts of the machine If installed

outdoors, the machine should be equipped with the shelter

to prevent the rain.

4.2 Assemble the parts

4.2.1Assemble column

Before installation and commission, you should

carefully read the manual. The modification without

the permission of the manufacturer will cause the

damage to the machine.

The person to install and commission must have some

knowledge of electrical.

The operators must under the special train.

Before installation, you must carefully check the

equipment list. If you have any question,

immediately contact the dealer or our company. To

secure the smooth installation and commission, you

should prepare the following common tools:

2 pc monkey wrench(10″), 1pc socket wrench, inner

hex spanner, 1 set of screw driver, 1pc hand hammer

and 1pc universal electric meter

4.2.2 Open the box

4.2.3 As per the instruction to open the box, open

the box. Remove the package material. Check if there

is not any damage during transportation and if the

spare parts are intact.

4.2.4 Take the package material from the working

field where to properly handle as per the local

laws and regulation.

4.2.5Assemble the column

Place the machine cabinet on the ground stably in

the working field. Open the accessory box. Take

out the rotation shaft assembly(Fig4-1 A)and

push-out shaft assembly(Fig4-2 B)and clean up

and spread the grease.

7

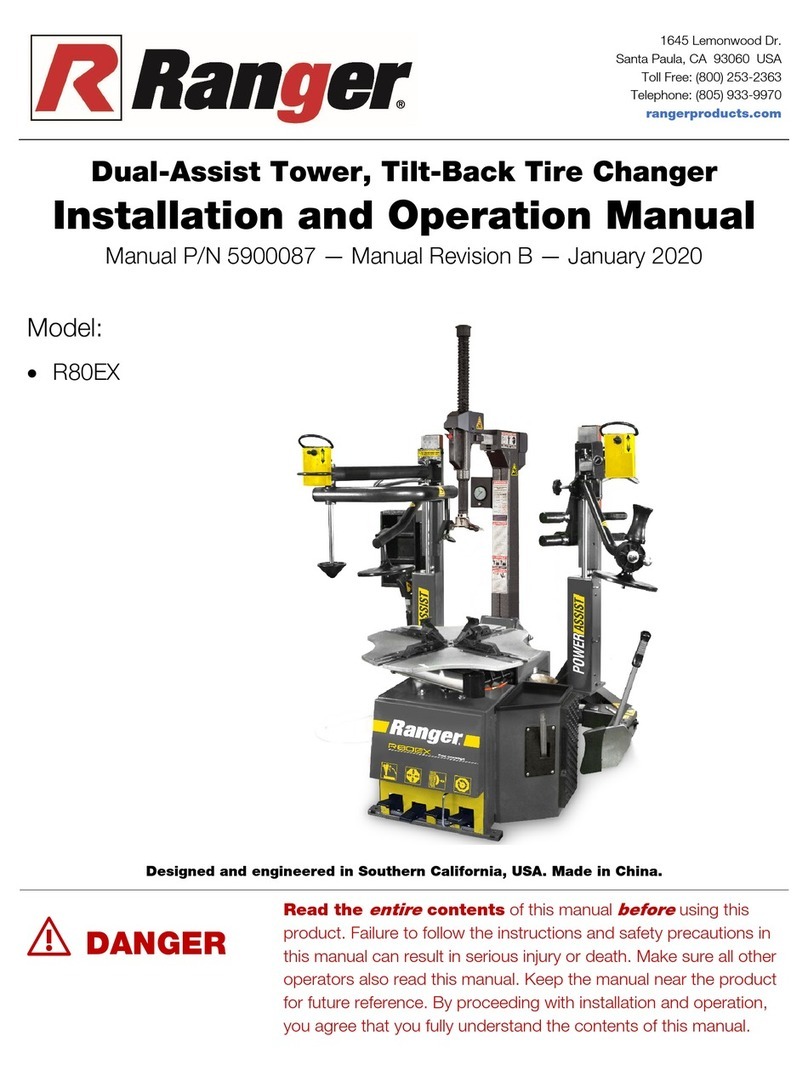

Fig 4-1

4.2.6 Unscrew off the fix screw on the side panel

(Fig4-2 A), Detach the side panel (Fig4-2 B)and the

fix screw on the tool box(Fig4-2 C). Take out the

tool box.

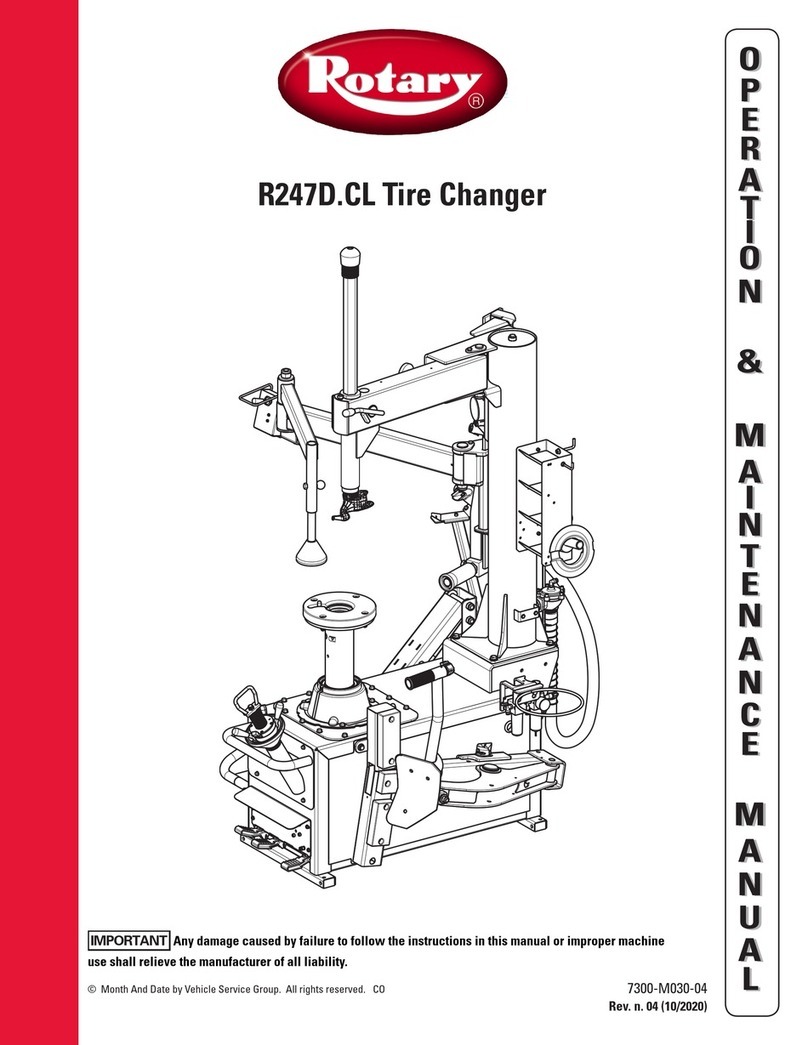

Fig 4-2

4.2.7 Rise up the column. Insert the PU hose at the

bottom (Fig4-3 A)into the open at the top of the

machine cabinet(Fig4-3 B). Adjust the position

of the column to align the rotation shaft bushing

(Fig4-4 A)to the rotation shaft seat at the upper

seat of the machine cabinet(Fig4-4 B). Take out

the nut and washer at one end of the rotation shaft

assembly(Fig4-1 A)and insert the shaft into the

hole, making the end face of the shaft at the

position 1mm lower than the plane of the seat. Screw

the washer and nut with the torque of 70N·m.

Fig 4-3

4.2.8 Tilt back the column. Cut up the tie belt

between the retention level (Fig4-5 A)and put out

cylinder piston rod(Fig4-5 B).

4.2.9 Position theΦ16hole under the column(Fig4-6

A), Detach the retaining washer at one end of

push-out shaft(Fig4-1 B), Insert through Φ16hole

and into the corresponding holes of the retention

rod(Fig4-6E)and push-out cylinder piston rod

(Fig4-6 D). And out from the hole at the other

end and mount the elastic washer.

Fig 4-4

8

Fig 4-5

4.2.10 Connect the PU hose described in the step

4.2.7 into the PU hose of the machine cabinet and

insert into the Tee of the air source pipe(Fig4-7)

Fig 4-6

2.11 Mount the horizontal arm protective cover and

detach the cap nut in the front(Fig4-8 A)and the

protective cover fix screw at the back(Fig4-8 B)

and fix screw(Fig4-8 C)on the vertical shaft cap

(Fig4-8 D)and take out the vertical shaft cap.

Fig 4-7

When you detach the vertical shaft cap,

you should support the vertical shaft to prevent

the slide of the vertical to cause the damage to

the machine and injury to the person.

4.2.12 Remove the package of the protective cover.

Mount the vertical shaft spring(Fig4-9 D), vertical

shaft cap and fix screw(Fig4-8 D)、( Fig4-8 C)and

fix.

4.2.13 Adjust the set screw at the 2sides of the

column. Release the nuts at the 2sides. Adjust the

screw heads making the gap between them and the side

plane of the column is 0.3mm(Fig4-10). Lock the

nuts.

9

Fig 4-8

4.2.14 Air test:

After connect the air source, press down the lock

valve press button Fig2-2 to lock the horizontal

arm. Step down column tilting pedal (Fig2-11)

and the column will tilt back by about 25 º. The

tilting speed of the column has been set to be about

2 seconds before the machine is delivered out of

the factory. After long us, the speed will become

too slow or too fast. You can use the speed adjust

valve at the two head of the push-out cylinder.

Release the nut and clockwise adjust the speed of

the screw to be slow and counterclockwise adjust

the speed of the screw to be fast. After adjustment,

tighten the nut.

Fig 4-9

Fig 4-10

4.2.15 Install the bead breaker arm

Fig 4-11

4.2.16 Unscrew the stop nut (Fig4-11 B)from the

top end of bead breaker piston rod and unscrew the

bolt connect on the machine cabinet(4-11 F)( 4-11

D). As per the instruction of Fig4-11, insert the

bead breaker blade (4-11 C)through the cylinder

piston rod(4-11 A). Hang one end of the bead breaker

arm spring(4-11 E)on the machine cabinet and then

insert the bolt(4-11 F)through the machine cabinet

and blade and use the nut and flat washer(4-11 D)

and bolt (4-11 F)to connect and fix. Tighten the

stop nut(4-11 B)and bead breaker cylinder piston.

Hang the other end of the bead breaker arm spring

(4-11 E)Fig 4-11 on the spring pin shaft(4-12 A)

L=0.3mm

10

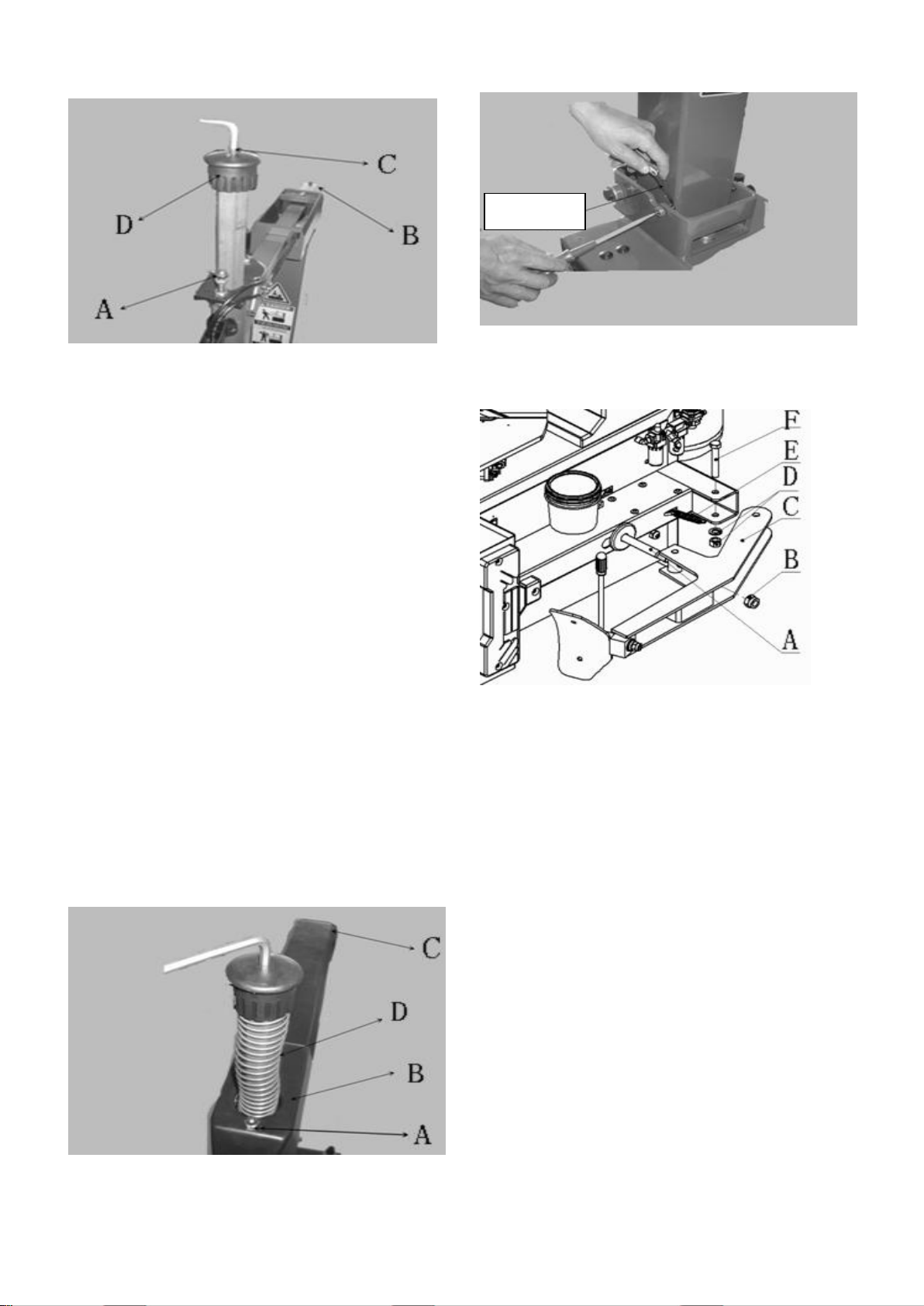

4.2.3 Air source

4.2.3 First take out the air source connect(Fig4-14

A)from the accessory box. Insert the connect at

the outlet of the air source (Fig4-13 A)。 After

installation, insert the air source quick insert into the air

source connect.

Fig 4-12

Note:When you install the air source, you should switch

off it!

Fig 4-13

Fig 4-14

4.2.2Install and connect pressure gauge

Via screw(Fig4-15 B),fix the pressure gauge

(Fig4-15 A)on the column(Fig4-15 C).

Fig 4-15

4.3Commision

All the work related to electrical must be

undertaken by the professional persons to secure

the power supply is correct and also secure the

phase connection is correct. The improper

electrical wiring will damage the motor and will

not be under the warranty.

Check whether the characteristic of your system meets the

requirement of the machine. If you have to change your

11

machine’s operation electrical voltage, please refer to the

Chapter 9 “electrical scheme”to undertake the necessary

adjustment on the terminator.

Connect the machine to the electrical

system which should be equipped with

fuse. Perfect grounding should meet

local national regulation. If

necessary, you should equip the

equipment with the electric leakage

protection device to secure the safety

running of the equipment. If the tire

changer without power supply plug, it is

necessary for the user to install one,

the min. electrical current of which

should be 16A and meet the relative

regulation and the electrical voltage of

the machine.

4.4Operation test

When step down the pedal(Fig4-17 K), the turntable will

rotate clockwise. When rise up the pedal(Fig4-17 K),the

turntable will rotate counterclockwise.

If the rotation direction of the turntable is

different from the direction described in 4.4,

change the wires at the 3-phase terminal.

Step down the pedal H, column U tilt back and once

rise up the pedal, the column will back to its work

position;

Step down the pedal I, 4 pieces of clamping jaw will

open and once rise up the pedal, they will close;

Step down the pedal J, bead breaker blade will go

to the work position and once rise up the pedal, it

will return to its original position;

When fix button at Y position, the tool arm U and

the horizontal arm C will be locked;

When fix button at Z position, the tool arm U and

the horizontal arm C will be released;

Note:When the tire mounted is heavier than 25Kg,

please select the lifting device model SR68 or the

other lifting device. But it is prohibited to lift

by the human force.

Fig 4-16

Fig 4-17

12

5.Operation

You must use machine after you read and

understand the entire manual and its warning.

Before use, deflate the air in the tire and remove all

the weights attached on the wheel.

The operation of tire changer consists of :a)bead breaking

b)demounting tire c)mounting tire

We suggest the tire changer should be

equipped with pressure adjust device.

5.1Breaking bead

When break the bead, you should be very

careful. When the bead breaking pedal drives

the bead breaker arm to move fast and

forceful, the bead breaker arm will cause

danger and crash to everything in its moving

area.

Check whether the tire is deflated. If no, deflate the air in the

tire and close the clamping jaw completely.

When break the bead, if the clamping jaw at the

open position, it will be very dangerous to the

hand of the operator. During bead breaking

process, never contact your hand with the wall

of the tire.

Lean the wheel against the wheel guard (Fig5-1 M), as

Fig5-2. Lean the bead breaker blade (Fig5-1 N)against the

bead 1cm from the rim. Note that the blade is leaned against

the tire not the rim. Step down the pedal(Fig5-1 J), move

the blade, when the blade moves to the limit of its travel,

release the pedal and rotate the tire slightly until the tire is

completely detached from the rim.

Fig 5-1

Spread the lubrication oil or the similar

grease on the bead. The lubrication oil

applied must be featured with non-toxic,

harmless and non-flammable. Not using

the grease will cause the serious damage to

the bead.

To avoid damaging the tube, you need to

position the core of the wheel at the right

side of the tool head with the distance of

10cm(Fig5-5)

13

Fig 5-2

5.2 Demounting tire

Before operation, you must secure all the

weights has been detached from the wheel

and check the deflation of the tire.

When the column tilts back, you must secure

there is not any person behind the column.

5.2.1Step down the pedal(Fig5-1 H)to tilt down the column.

Step down the clamping jaw open/close pedal, the jaw will

open.

Use the tire press block to press the center of the rim and

then step down the clamping jaw open/close pedal to clamp

the tire on the turntable.

During the process to lock the rim, never

place your hand under the rim. The correct

method to fix is the tire is just at the center

of the turntable.

Outer clamping

Refer to the position of the

clamping jaw on the

turntable(Fig2-1 F and

Fig1-5)to place the tire.

Step down the pedal

(Fig5-1 I)to the middle

position. Place the tire on

the clamping jaw and

press down the rim. Step

the pedal(Fig5-1 I)to the

limit position.

Inner clamping

Refer to the position of the

clamping jaw(Fig2-1 E)

to position the tire to make it

completely closed.

Place the tire on the

clamping jaw and press

down the rim. Step the pedal

Fig5-1 I)to open the jaw to

clamp the rim.

Position the lock press button at the position(Fig4-16 Y)to

release the lock of the tool arm M.

5.2.2 Move the tool arm downwards making the tool head

above the rim. Position the lock button at the position

(Fig4-16 Z)to lock the entire tire demounting assembly.

This kind of lock is the vertical and horizontal lock. The

distance from the tool head to the rim is 2mm(Fig5-3).

Insert the crowbar in between the bead and tool head (Fig5-5)

making bead move above tool head.

Never place your hand on the wheel. When

the column back to its work position, the

hand of the operator will be crashed in

between the tire and rim,

Secure the rim is firmly fixed on the

clamping jaw.

14

Fig 5-3

Necklace, bracelet and loosen cloths or the foreign

objects near the moving pars will cause danger

5.2.3 As shown in the figure, use the helper press

roller to press the tire.

5.2.4 Move the tool head downward to reach out the

tool hook.

5.2.5 until the tool hook deeply into the inside of

the tire

5.2.6 Push upward the tool head handle valve to take

back the tool hook. At this moment, the tool hook

has detached the tire from the rim.

5.2.7 Step down the main shaft rotation switch to

make the turntable carry the tire rotates

clockwise.

15

5.2.7 Use the tire support disk on the helper.

5.2.8 Press down the tool hook handle to extend the tool

hook.

5.2.9 Use your hand to rise up the outside of the tire and

press upward tool hook handle to hook up the tire.

5.2.10Step down the main shaft rotate switch to make the

turntable drive the tire clockwise rotate.

5.3 Mounting tire

5.3.1Place the tire repaired and the new tire on the rim as

shown in the following figure.

5.3.2 Clockwise rotate the turntable to drive the rim.

16

5.3.3 As the figure shown, press the tire press roller and

the tire presser under the edge of the rim.

5.3.4Clockwise rotate the turntable to drive the rim.

The most important is to check the rim and tire

to prevent the explosive during re-inflation

process. Before installation, you should secure:

Tire and tire thread fiber not damaged. If you

find the damage, do not mount the tire;

The rim without dent and warp by visual check.

Note that there is not any small scratch inside

the Alum alloy rim. These are dangerous,

especially while inflation.

Use the special grease to lubricate the bead for fear the bead

to be damaged and convenient to operate.

When lock the rim, do not place the hand under

the tire. The correct operation is to position the

tire at the center of the turntable.

22inch turntable clamping range:10-20inch is the inside

clamping without washer;12-24inch is the outside clamping

While the column is tilting, you should make

sure that nobody is standing behind the column.

If the tire changer handle the same size of the

rim, it is no need to frequently lock or release

the lock of the tool arm. What you need to do is

only to tilt back and forward the column and

17

keep the tool arm at the work position.

Never place your hand on the wheel. The

column back to its work position will crash the

operator ( in between the rim and tool head.)

Move the tire making the bead pass under the tool head. The

buckling part of the bead will lean against the back of the

tool head. Use your hand to press the bead into the groove of

the rim. Step down the pedal(Fig5-1 K)making the turntable

rotate clockwise. Continue this operation until the tire is

completely into the rim.

To prevent the industrial accident, when the

turntable rotates, keep your hand and the other

part of your body far away from the tool arm.

Put in the tube, repeat the above operation

When demount and mount the tire, the turntable

will clockwise rotate. Counterclockwise rotate

on the condition that the machine turns off

causing the wrong operation and must make

correction.

6. Inflation

You should be very carefully when inflate the

tire. Seriously follow the following instruction

due to design of the tire changer does not

consider the prevention the persons around from

the accidental tire burst.

Tire burst will cause the serious injury or death

to the operator. Carefully check whether the

size of the rim and tire is the same. Before

inflation, you should check whether there is

any fault and abrasion on the tire. After each

inflation, you should check the pressure. All

of our tire changers is limited to the max.

inflation air pressure of 3.5 巴equal to

51psi. No matter how, it will not exceed the

pressure value suggested by the manufacturer.

And keep your hand and body far from the

tire.

6.1Use the inflation gauge to inflate the tire. On

the condition of the standard mode, our tire

changers are equipped with the inflation gauge. The

process is as follows:

①Connect the inflation gauge with the core of the

tire.

②Check whether the size of the tire is mating with

the size of the rim.

③Check whether the bead has been fully lubricated.

If necessary, undertake the lubrication.

④Inflation,Check the air pressure of the pressure

gauge.

⑤Continue inflation. Check air pressure while

inflation.

18

Danger of explosive!

When inflate the tire, do not exceed 3.5bar

(51psi); If need relative high air pressure,

detach the tire from the turntable and place

into the special tire cage to inflate, Never

exceed the inflation pressure suggested by the

manufacturer. Keep your hand and the body

behind the tire being inflated. Only can the

person under the professional training inflate

the tire. The other persons should not stand

near the tire changer and operate.

6.2Use the IT system to inflate the tire

When inflate the tubeless tire, it is convenient to use IT

system to inflate.

During this process, the noise can reach

85dB.At this time, we suggest to use the

noise protection.

①Fix the wheel on the turntable and connect the

inflation head with the core of the tire.

②Check whether the size of the tire is mating with

the size of the rim.

③Check whether the bead has been fully lubricated.

If necessary, undertake the lubrication.

④Step down the pedal to the middle position.

⑤Inflation,Check the air pressure of the pressure

gauge. Continue inflation. Check air pressure while

inflation until the pressure reach the pressure

value required.

Danger of explosive!

When inflate the tire, do not exceed 3.5bar

(51psi); If need relative high air pressure,

detach the tire from the turntable and place

into the special tire cage to inflate, Never

exceed the inflation pressure suggested by the

manufacturer. Keep your hand and the body

behind the tire being inflated. Only can the

person under the professional training inflate

the tire. The other persons should not stand

near the tire changer and operate.

7. Helper installation and

operation(helper is optional)

PL330 left helper and AL335 right helper is the

important assist device to the tire changer. You can

attach one or both to the tire changer with the

turntable larger than 20 ″, helping demount and

mount the stiff and run flat tire difficult or

impossible to complete only be human force.

7.1 Left helper installation

Switch off the power supply and air source

before installation!

19

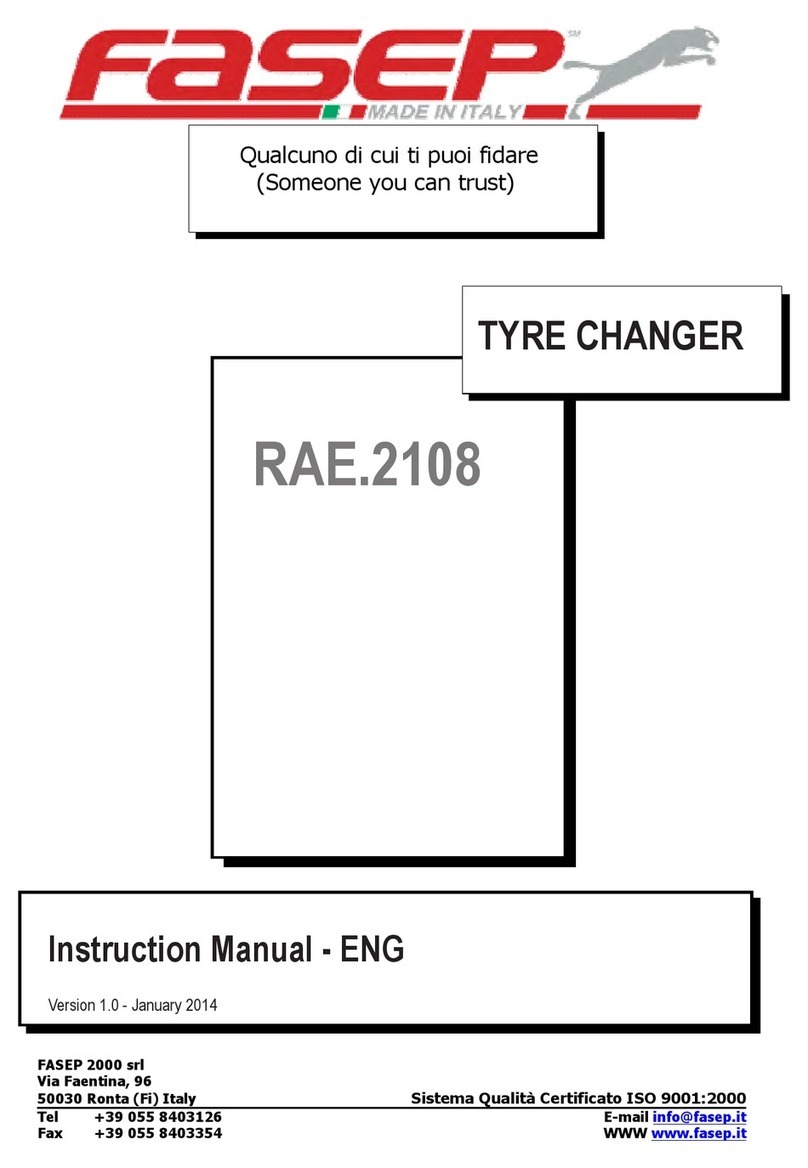

Fig 7-1

Fig 7-2

7.1.1 There is the installation hole prepared at the

back of the base plate of the machine cabinet of each

machine that can handle the tire more than 20″.

Before installation, detach the side panel and then

the T rubber plug.

7.1.2 Open the package box of PL330 helper and then

check whether the spare parts is are intact as per

the packing list Fig 7-2. And then take out the base

frame assembly(Fig7-1)and detach the screw and

washer on it.

7.1.3 Push the base plate of the base assembly into

the machine cabinet from left back, making the

thread hole align to the reinforcement hole. Use

the bolt and washer to fix(Fig7-2).

7.1.4 Place the main frame support(Fig7-3 A)

on the base assembly Fig 7-3. Align and use the screw

unscrewed before Fig(7-3)to fix. Remind not too

tight.

Fig 7-3

Fig 7-4

7.1.5 Use the fix bracket(Fig7-4 A)to connect the

main frame support with the machine cabinet and

insert the screw to fix.

7.1.6 Use the Y Tee to connect the air source

(Fig7-5 A)and the other end is connected with the

helper pressure valve inlet.

7.1.7 Connect the air route. Insert the tire press

roller connect rod(Fig 7-6 A)into the rotating

arm rotating shaft hole(Fig7-6 B). Operate the

handle direction changing valve to make the tip of

the tire press conic roller align with turntable

Table of contents

Popular Tyre Changer manuals by other brands

Hofmann

Hofmann monty 3850 Operation manual

TMG

TMG TMG-TTC26 product manual

Hofmann Megaplan

Hofmann Megaplan Megamount Twister EVO CP Installation, operation and maintenance guide

SICE

SICE S 42 instruction manual

Mondolfo Ferro

Mondolfo Ferro Aquila AS 914 TI Operator's manual

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES Coats 50 manual