4 • Important: Always read and follow operating instructions.

Operating Instructions

This unit must be properly operated and properly

maintained to help avoid accidents that could injure

the operator or bystanders, or damage the unit.

This section of the Operating Instructions manual

review basic operations and use of controls. These

instructions should be reviewed with all employees

before they are allowed to work with the machine.

Keep these instructions near the machine for easy

reference.

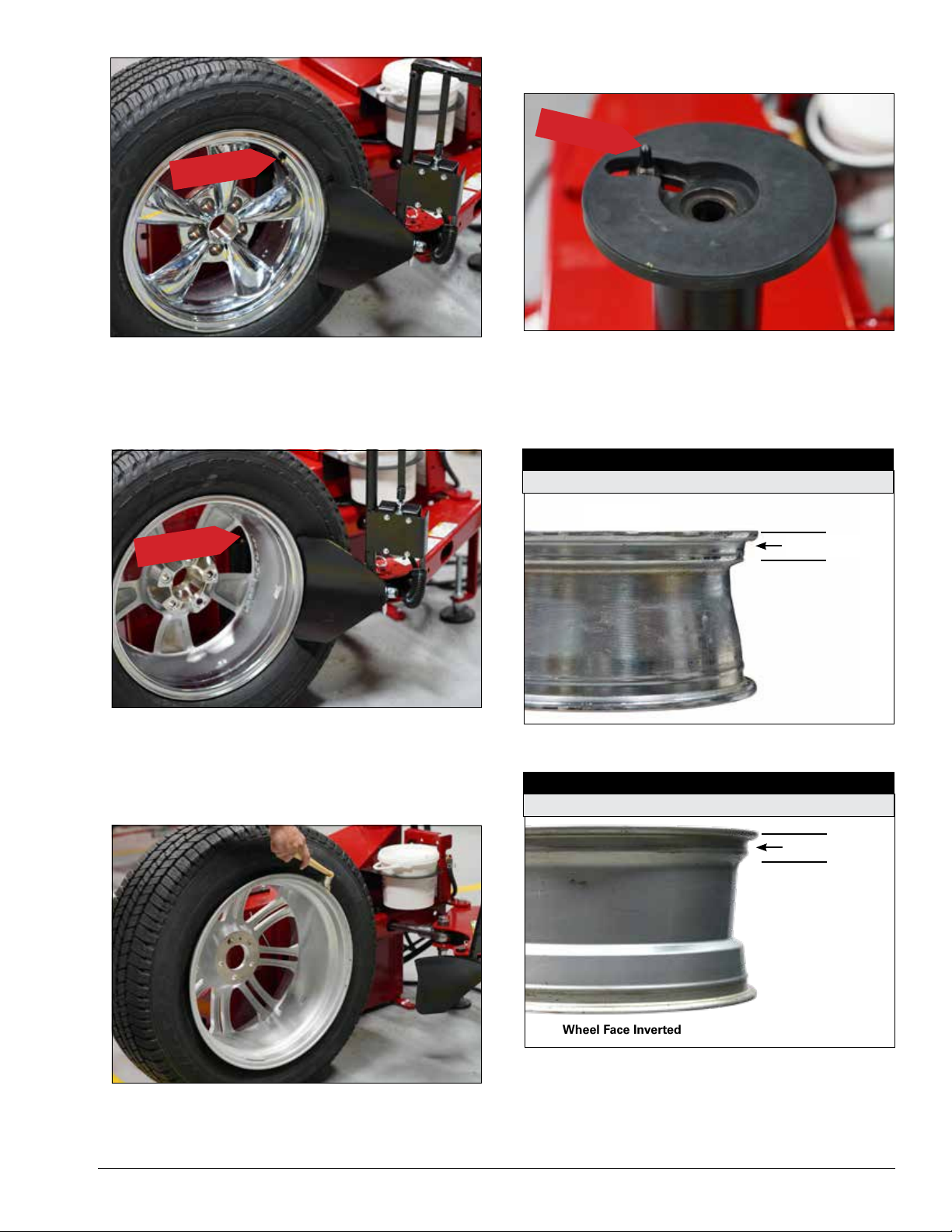

Tire Bead Loosening and Demounting

This machine may operate differently from

machines you have previously operated.

Practice with a regular steel wheel and tire

combination to familiarize yourself with

the machine’s operation and function.

NOTE: Remember to remove all weights from

both sides of the wheel. Weights left on backside

of wheel may cause the wheel to be clamped

unleveled. This may result in the combination

mount/demount tool contacting the rim causing

scratches. On alloy wheels, always rotate the

wheel one turn after setting the Duckhead mount/

demount tool to insure proper wheel clamping.

NOTE: Always review with the owner any nicks

and scratches on expensive wheel and tire combi-

nations prior to servicing.

NOTE: Review the performance wheel section of

this manual prior to servicing performance tire/

wheel combinations.

Loosening the beads on a partially or fully

inflated tire is unsafe and causes excess

movement and friction against the bumper

pads and excessive wear on pivots. Deflate

the tire completely to prolong the life of

your machine.

1. Deflate the tire completely by removing the valve

core from the valve stem (figure 1). Be cautious and

do not smoke as a flammable gas could have been

introduced into the tire at some time.

Figure 1 - Remove Valve Core to Deflate Tire

Tires are always installed and removed

from the rim’s narrow side.

NOTE: Always loosen the bead on the narrow

side of the wheel’s drop center first (tire removed

in figure 2 for clarity).

Figure 2 - Determine Narrow Side of Wheel

NOTE: Use extra care in positioning the bead

loosener shoe on larger wheels/tires, and on alloy

wheels. Make sure the shoe rests next to but not

on the rim, and not on the tire sidewall.

2. Actuate valve to position the bead loosener shoe

away from the machine and roll wheel into position.

The valve stem should be in the 2 o’clock position to

accommodate a possible asymmetric safety hump

type rim. Position the bead loosener shoe against

the tire next to, but not on, the rim. Actuate the bead

loosener handle to position the shoe and loosen the

bead. It may be necessary to loosen the bead in

multiple locations around the tire (figure 3).

Narrow Side

Drop Center

Long Side