3

•Before turning the device on, make sure that (in addition to the instructions above):

oeveryone inside the region of potential laser exposure wears laser safety

goggles that block laser radiation at 690 ± 10 nm and/or at 810 ± 10 nm

othe laser output and laser light blockers/absorbers are aligned and positioned in

such a way that the direct/reflected/scattered laser beam will not be dangerous

to anyone

•If the laser is to be used at high duty cycle and if the beam is to be focused tightly, the

possible risk of fire or explosion in the presence of flammable materials has to be

taken into account

•Ensure that there is no risk of unintentional voltage signal/peak (e.g. static discharge)

at the Set Mode I/O (SMIO) connector, since this may enable/disable laser output (see

Chapter 3 for more information)

•Other instructions:

oDo not make ANY modifications to the device by yourself

CAVILUX Smart is not certified for medical use

oDo not try to repair the device by yourselfo

oIt is strictly forbidden to open the cover of the laser unit or the control unit.

Otherwise serious damage or injury to the user or to the device may occur.

Laser unit contains gallium arsenide, which is a known human carcinogen

oDo not expose the system to moisture, rain or condensing environment

Before turning the device on, ensure that all connections are properly made

oExcessive vibration or strong mechanical impact may damage the equipmento

oThe operating temperature of CAVILUX Smart is +10…+40 °C. Do not

expose CAVILUX Smart to excessively low or high temperatures

oIf you are uncertain about any issue related to safety or proper operating

conditions, please contact your vendor or Cavitar

CERTIFICATIONS:

•Cavitar Ltd. is an ISO 9001:2008 certified company

•EC- cde laration of conformity

othe device fulfils the requirements of the following directives/standards:

Low Voltage Directive (LVD) 2006/95/EC

Directive of Electromagnetic Compatibility (EMC) 2004/108/EC

Laser Safety Standard EN/IEC 60825-1

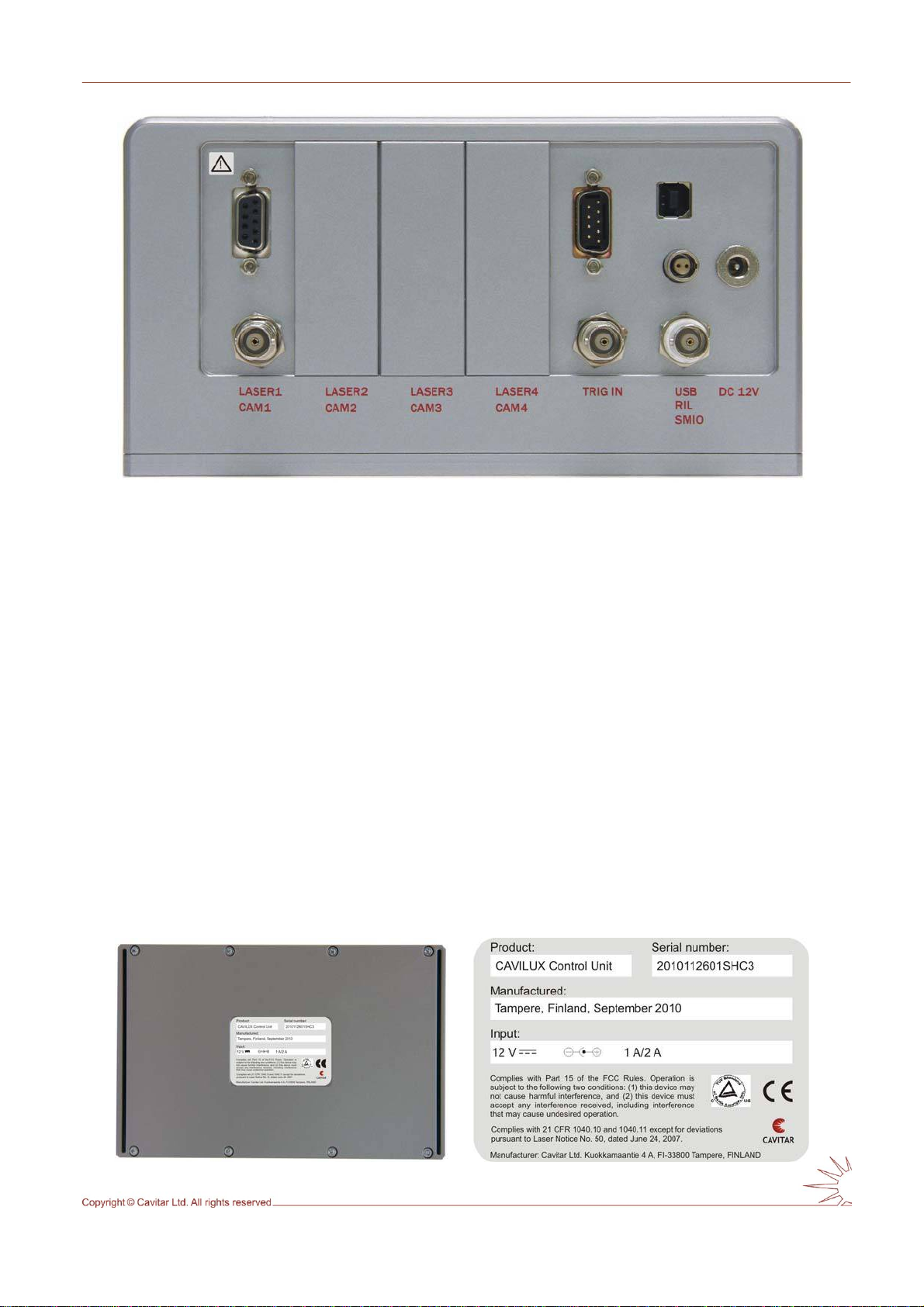

•Cer ctifi ations for USA and Canada

oComplies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007.

oThis device complies with Part 15 of the FCC rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including

interference that may cause undesired operation.