NOTE: Please read instructions before drilling any

holes or marking out hole centres.

Mark both sides of the door using the template (flip

template over to mark other side).

DO NOT drill right through the door as alignment

issues will occur. Only drill to centre.

There are five stages to fitting the Mortice Case:

Stage 1: Mark drilling positions for lock case.

Stage 2: Mark drilling positions for door furniture to

be installed

Stage 3: Prepare door by mortising and drilling holes.

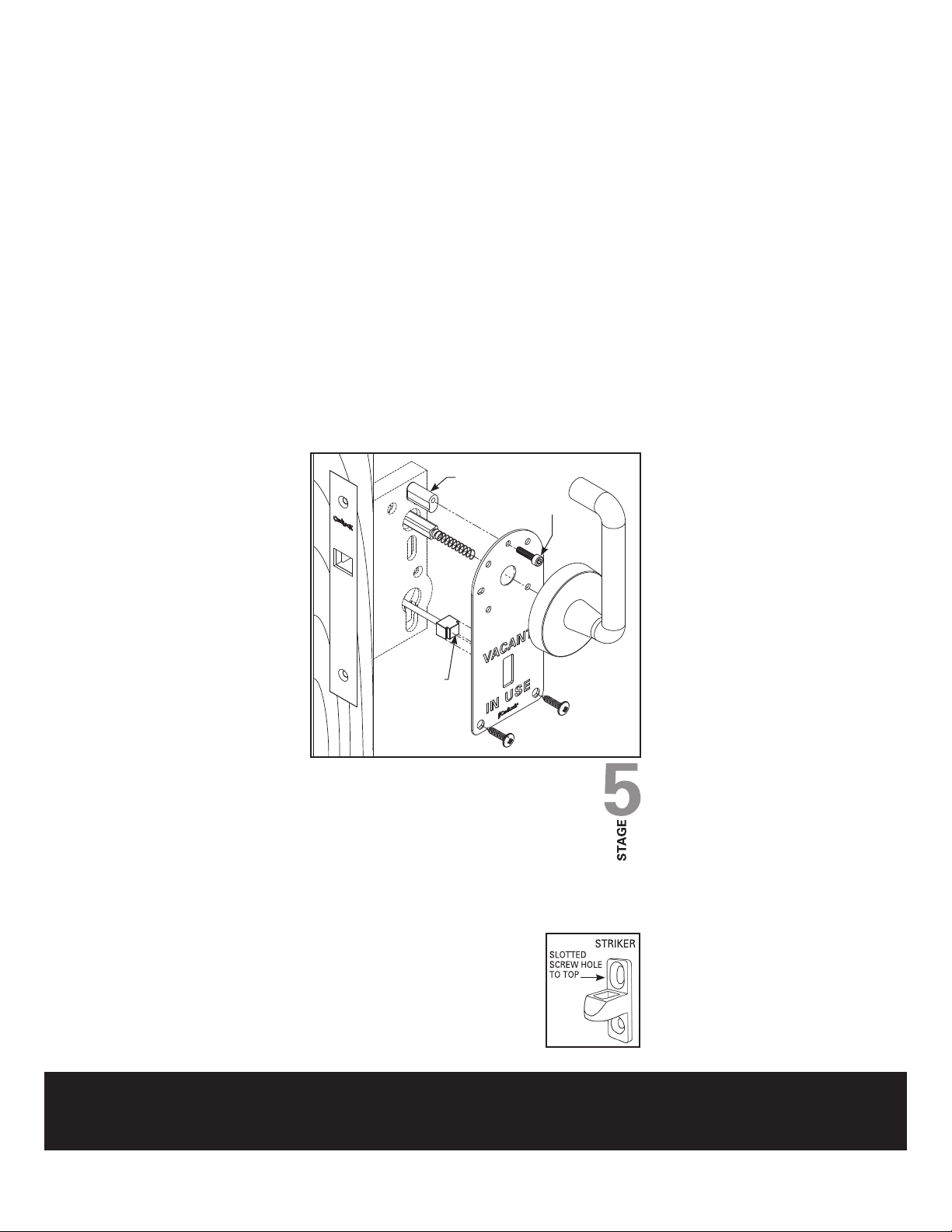

Stage 4: Fit lock & door furniture.

Stage 5: Fit striker.

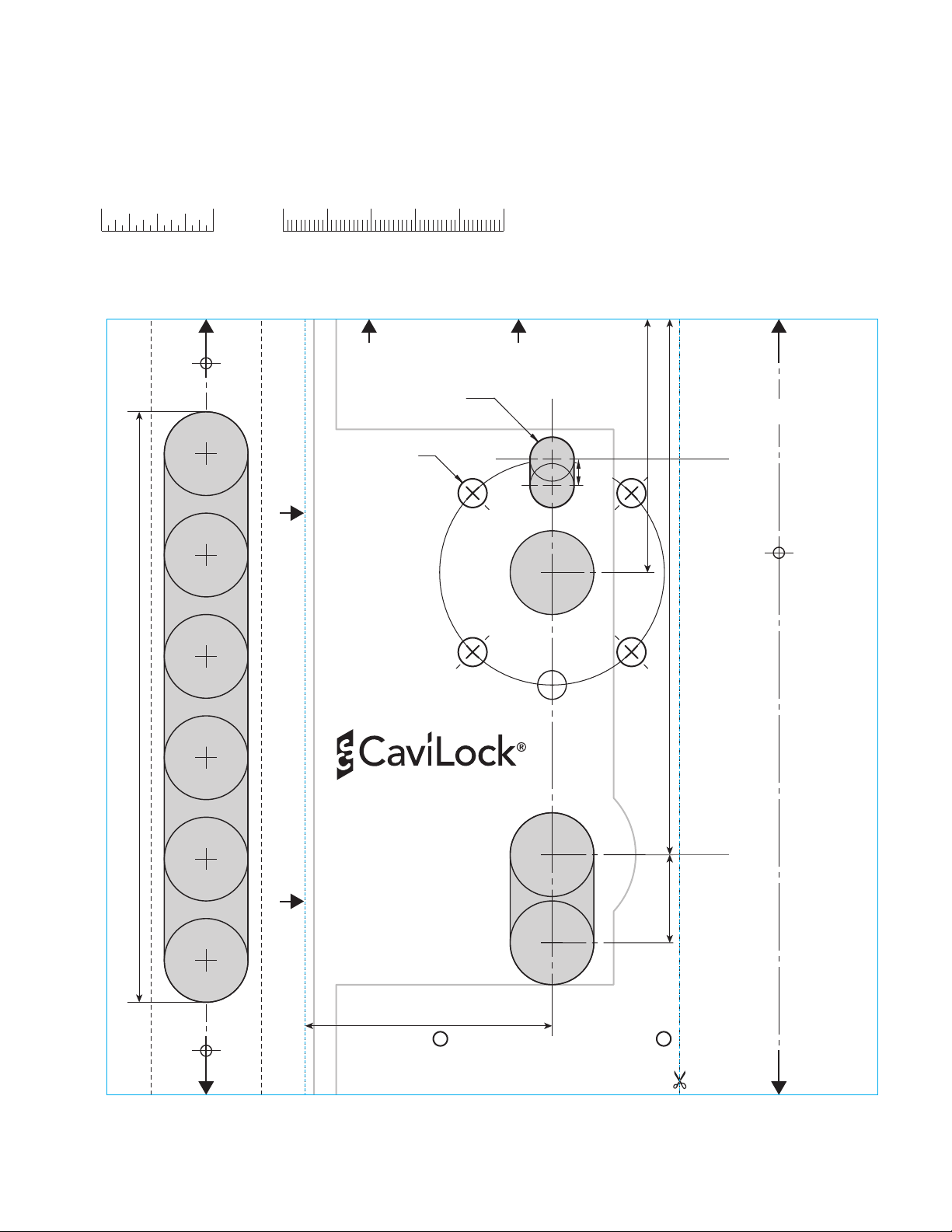

Stage 1 - Mark Drilling Positions

for Lock Case

1. Mark chosen height of lock on face of door.

Height is normally measured to centre of square

spindle (Hole 9).

2. Mark ‘Height Line’ at top of template 57.5mm

(2-9/32”) above Hole 9 or 121.5mm (4-25/32”) above

Hole 10 on front edge and both faces of door.

3. Make a vertical centre line on front edge of door.

Universal Hole Positions

Hole # Hole Diameter Depth

1 - 6 19mm 3/4” 77mm 3”

7 & 8 2.5mm 3/32” 25mm 1”

Indicator Lock Hole Positions

Hole # Hole Diameter Depth Door Side

9 - 11 19mm 3/4” To Centre of Door Both

12 or 13 6.5mm 1/4” To Centre of Door Both

14 &15 10mm 25/64” To Centre of Door Both

4. Align top edge of template with height line and

arrows to vertical centre line.

5. Mark universal hole positions (Holes 1-8) for lock

case using a sharp nail or pencil.

1

2

3

4

5

6

8

7

FOLD HERE AND PLACE ON CORNER OF DOOR

134

mm

(5-9/32”)

9

12 12

1212

16

13

14

15

10

11

Backset 56

mm

(2-13/64”)

CL100ZA525

02.2018

HEIGHT LINE

DRILLING TEMPLATE FOR CL100 MORTICE

READ FITTING INSTRUCTIONS

121.5

mm

(4-25/32”)

20

mm

(25/32”)

57.5

mm

(2-1/4”)

STRIKER TEMPLATE

Ø

10

mm

(25/64”)

4x Ø

6.5

mm

(1/4”)

6

mm

(15/64”)

Stage 2 - Mark Drilling Positions

for Door Furniture

1. Highlight correct drilling options required

for handle and use a sharp nail or pencil to

mark required hole centres. Holes 12-13 to be

vertical or diagonal fixing holes at the correct

hole centres to suit the lever handles being

used.

Stage 3 - Mortice & Drill Holes

DO NOT drill right through the door.

Alignment issues will occur. Drill to centre on

both sides for through holes. Check Stage 2

chart for hole depth.

1. Drill Holes 1-6. Make sure drilled holes are

straight and level.

2. Chisel out remaining wood between holes indicated

in shaded area on template to create a slot.

Note: Maximum slot length not to exceed 134mm

(5-9/32”).

3. Drill Holes 7 and 8.

4. Remove face plate from lock case and temporarily

screw lock case in place. Mark around outside edge

of inner forend then remove lock.

5. Router out marked area to a depth of 7mm (9/32”).

Important: Recess of front section must be routered

flat and even. Long term damage will occur if not

done correctly.

6. Drill Holes 9 to 11.

7. Remove remaining wood from oval shaped slot

between Holes 10 and 11.

8. Drill holes for fixing handles using marks from

Stage 2.

Height

line

Centre

line

Front

edge

of

door

Face

plate

Inner

forend Drilled

holes

7 & 8

Router

out 7mm

(9/32”)

INDICATOR LOCK Fitting Instructions

1

STAGE

STAGE

2

STAGE

3